13

SERVICING

.

We recommend an annual service by an authorised service agent to maintain efficient

appliance performance. To arrange service, please contact your authorised local Service

Agent giving full details of the model, serial number and date of purchase.

Manufactured by:

THETFORD Limited,

Unit 6 Brookfields Way,

Manvers,

Rotherham,

S63 5DL,

UK.

Service Instructions

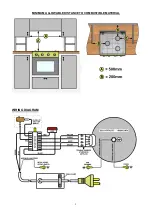

1. Disconnect from gas and electricity supply

Lift and remove the bottom plinth to gain access, and then disconnect the gas supply.

If the appliance is Dual Fuel, the electric supply must be disconnected.

2. Remove hob surface

Isolate and disconnect from gas supply and electricity supply if Dual Fuel. Lift off the

Panrest and remove the two screws securing each burner spreader. Remove front

fascia by removing all push on control knobs and unscrew the two recessed fixed nuts

and both fascia retaining screws. Carefully lift off the fascia and if spark ignition fitted

remove the two spade connectors from the rear of the toggle switch. Remove the two

central screws securing the pressing to the rear box section. Remove the two front

retaining screws located each side and accessed through the outer slots on the angled

front. Grasp the hob by the angled front face; carefully lift the hob surface from the front

to allow the rear edge to unhook from the rear box section. Note: - On Dual Fuel

appliances, remove the hotplate rear cover and disconnect the power leads. The hob

surface should be placed onto a suitably protected surface.

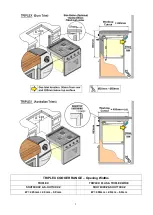

3. Remove appliance from housing

Disconnect from gas and electric supply. Open the oven door and remove the 2 screws

from each side trim - note the appliance can either be front or side fixed, see under

Fixing,

page 13. Open the glass lid and remove the 2 screws from each side trim.

Carefully slide the appliance out one third and check for any possible snagging of wires

or pipes. If the appliance is Dual Fuel, disconnect supply lead from rear terminal block. If

OK, lift appliance out onto a suitable surface.

•

Shut off gas supply at isolating valve and ensure all parts are cool before

cleaning or servicing

•

All servicing must be carried out by an approved competent person.

•

After each service the appliance must be checked for gas soundness

•

Do not modify this appliance.

•

No parts other than those supplied by the manufacturer should be used on

this appliance.