6-1

6. Lubrication

LM Guide

6.

Lubrication

It is necessary to use a good quality lubricant when using an LM Guide. Usage with no lubrication

may increase wear on the rolling elements and shorten the service life.

A lubricant has the following effects.

(1) Minimizes friction in moving elements to prevent seizure and reduce wear.

(2) Forms an oil film on the raceway to decrease stress acting on the surface and extend rolling

fatigue life.

(3) Covers the metal surface in an oil film to prevent rust formation.

To fully bring out the LM Guide’s functions, it is necessary to provide lubrication according to the

usage conditions.

It is necessary to study the mounting positions of the grease nipple and piping joint according to

the installation direction.

If the LM Guide installation direction is other than horizontal use, the lubricant may not reach the

raceway completely. Be sure to let THK know the installation direction and the exact position in

each LM block where the grease nipple or the piping joint will be attached. See the general

catalog for the installation direction of the LM Guide.

Even with an LM Guide with seals, the internal lubricant gradually seeps out during operation.

Therefore, the system needs to be lubricated at an appropriate interval according to the usage

conditions.

6-1

Lubrication Interval

6-1-1

Grease Lubrication

How often grease should be replenished varies depending on the usage conditions and

environment. We recommend greasing the system approximately every 100 km traveled (three

to six months). Final greasing interval/amount should be set at an actual machine.

Normally, relubricate using the same grease type and through the lubrication hole or grease

nipple provided on the LM Guide. Mixing different types of grease may deteriorate the system’s

performance due to increased consistency or other such factor.

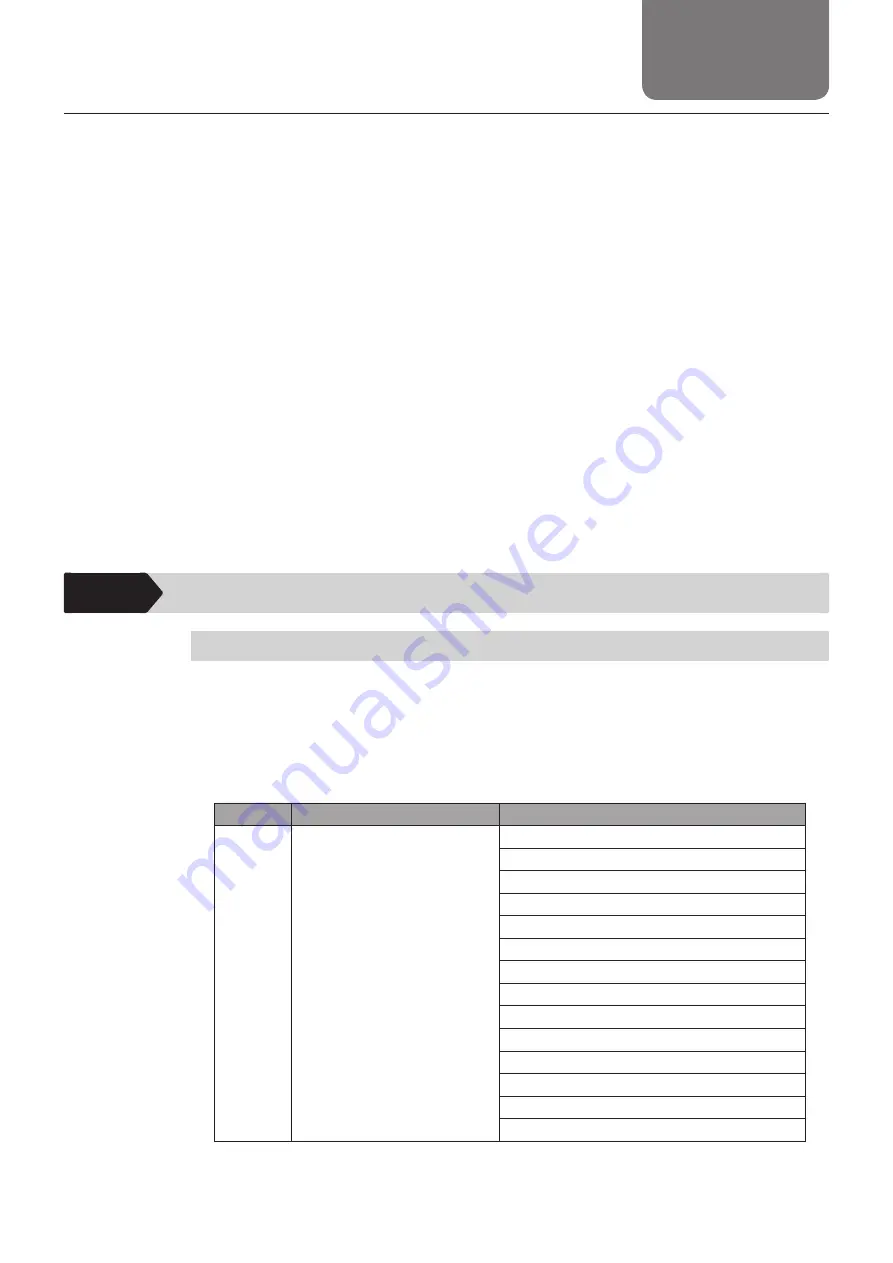

Lubricant

Type

Brand name

Grease

Lithium-Based Grease

Urea-Based Grease

Calcium-Based Grease

AFA Grease

(THK)

AFB-LF Grease (THK)

AFC Grease

(THK)

AFE-CA Grease (THK)

AFF Grease

(THK)

AFG Grease

(THK)

AFJ Grease

(THK)

L100 Grease

(THK)

L450 Grease

(THK)

L500 Grease

(THK)

L700 Grease

(THK)

Alvania Grease S No.2 (Showa Shell Sekiyu)

Eponex Grease No.2 (Idemitsu Kosan)

or equivalent

*The recommended grease will vary according to the usage conditions and environment.