Form 405, Page 6

Instructions and Requirements for Installing

Horizontal Vent Terminal/Combustion Air Inlet

Option CC6

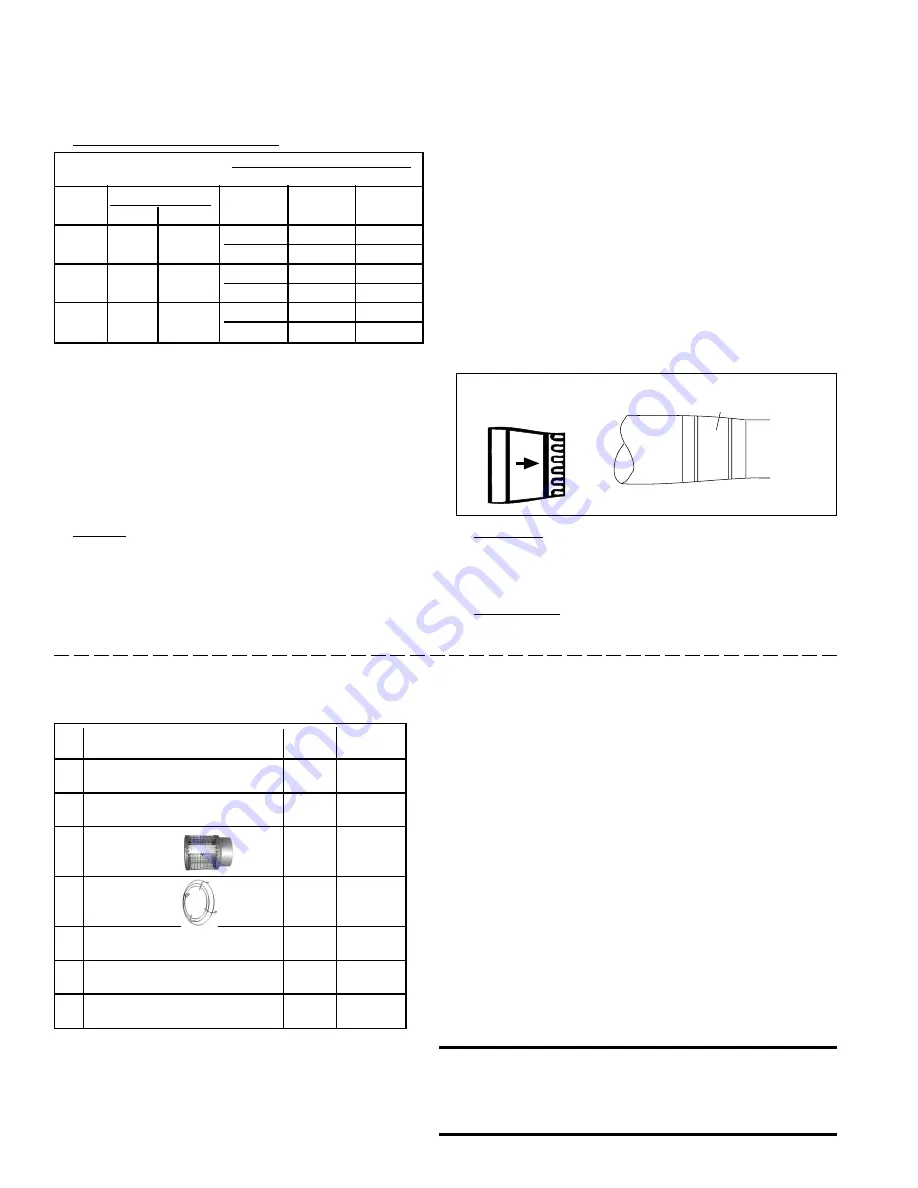

4. Pipe Diameter and Length

Maximum Pipe Length from Heater to Concentric Adapter -

minimum length is five feet (1524mm)

Model

Pipe Diameter

Maximum 90° Elbow 45° Elbow

CAUA

Vent

Inlet Air

Length

Equals*

Equals*

150-200

5"

5"

40 ft

5 ft

2.5 ft

12.2 M

1524 mm

762 mm

250

5"

6"

50 ft

5 ft

2.5 ft

15.2 M

1524 mm

762 mm

300-400

6"

6"

50 ft

5 ft

2.5 ft

15.2 M

1524 mm

762 mm

*Reduce maximum length by this amount for each elbow.

7. Venting and Combustion Air (cont'd)

7A. Venting and Combustion Air Requirements for Separated-Combustion

Installation (must use either Option CC2 or CC6) (cont'd)

Option CC6 Package includes:

Qty

Description

150,

250, 300,

200

350, 400

1

Complete Horizontal Vent Kit

157158

82131

(Same as Option CC6)

1

Concentric Box Assembly

155392

68404

(See Figures 3A and 3B)

1

Screened

155096

53316

Exhaust Assy

1

Inlet

151755

124940

Guard

4

#10-16x1/2" lg Screws (to

37661

37661

attach the inlet guard)

1

Rubber seal for vent pipe opening

164492

164493

in concentric adapter

1

Tube of high temperature (450°F)

53335

53335

silicone sealant

Concentric Pipes (the vent pipe runs concentric through the out-

door portion of the combustion air pipe) - Sizes 150 and 200 require

a 6" diameter combustion air pipe for outdoor portion and a 4" diam-

eter vent pipe through the concentric adapter to the terminal; Sizes

250-400 require an 8" diameter combustion air pipe for the outdoor

portion and a 5" diameter vent pipe through the concentric adapter to

the terminal.

Length depends on building construction; specific requirements are

included with the concentric adapter kit instructions.

5. Joints

Determined by type of pipe - Provide field-supplied vent pipe as

specified in the Table on page 4.

•

If using single wall, 26-gauge or heavier galvanized pipe, secure

slip-fit connections using sheet metal screws or rivets. Seal all

joints. Seal combustion air pipe with pressure sensitive tape ordi-

narily used for warm-air ductwork. Seal flue exhaust pipe with

Either collar

or smaller

diameter pipe

Taper-type Connector

Secure joints with sheetmetal

screws and seal.

Field-supplied installation requirements:

•

Thimble (a thimble is not required if wall is of non-combus-

tible construction)

•

Flashing

•

Vent pipes (see requirements on pages 4 and 6)

•

Combustion air pipes (see requirements on pages 4 and 6)

Installation Instructions for Option CC6

1. Determine the location on the outside wall for the vent terminal

(Applies to all horizontal vent kits). In most applications, the terminal

would be on a level with the heater mounting height. Allow 1/4" per foot

downward pitch toward the terminal for draining of condensation.

The distance of the termination of the horizontal vent from adjacent public

walkways, adjacent buildings, openable windows, and building openings

must be in accordance with local codes or, in the absence of local codes,

must conform with National Fuel Gas Code. Local codes supersede all

provisions in these instructions and in the National Fuel Gas Code. Mini-

mum clearances for the horizontal vent terminal are as shown in the table on

page 7.

Products of combustion can cause discoloration of some building finishes

and deterioration of masonry materials. Applying a clear silicone sealant

that is normally used to protect concrete driveways can protect masonry

materials. If discoloration is an esthetic problem, relocate the vent or install

a vertical vent.

WARNING: All vent terminals must be positioned or

located away from fresh air intakes, doors and

windows to preclude combustion products from

entering occupied space. See Hazard Levels, page 2.

Reducer

Airflow

Figure 4 - When joining different pipe diameters, use taper-

type pipe connectors

either tape suitable for 550°F (such as Option FA1, P/N 98266) or

high-temperature (450°F) silicone sealant.

•

If using Category III vent pipe, follow the pipe manufacturer's in-

structions for joining pipe sections.

In Concentric Pipes (outdoor portion) from Concentric Adapter

Box to Air Inlet and Vent Terminal - Follow the installation instruc-

tions for the specific option (CC6 for horizontal vent; CC2 for vertical

vent).

Joints Requiring Taper-type Connections (See Figure 4) - When

the diameter of the pipe in the vent pipe run is different from the vent

pipe in the terminal section, the joint must be made with a taper-type

pipe connector. Install the connector no more than 6" (152mm) from the

concentric adapter box. A 5" to 4" reducer is required in the vent pipe on

Sizes 150 - 200; a 6" to 5" reducer is required on Sizes 300 - 400.

6. Support

Support horizontal runs every six feet (1829mm); do not rely on the

heater or concentric adapter for support of either horizontal or vertical

pipes.

7. Clearance

Clearance from the vent pipe to combustibles is 6" (152mm). Do not

enclose the vent pipe.

•

Mounting brackets for concentric adapter box (or box may be

mounted flush, depending on building construction)

•

Taper-type reducers as required (see requirements above)