DISASSEMBLY

NOTE: To avoid confusion, service one end of the compressor at a time.

STEP 1.

Clean loose dirt from the outside of the compressor.

STEP 2.

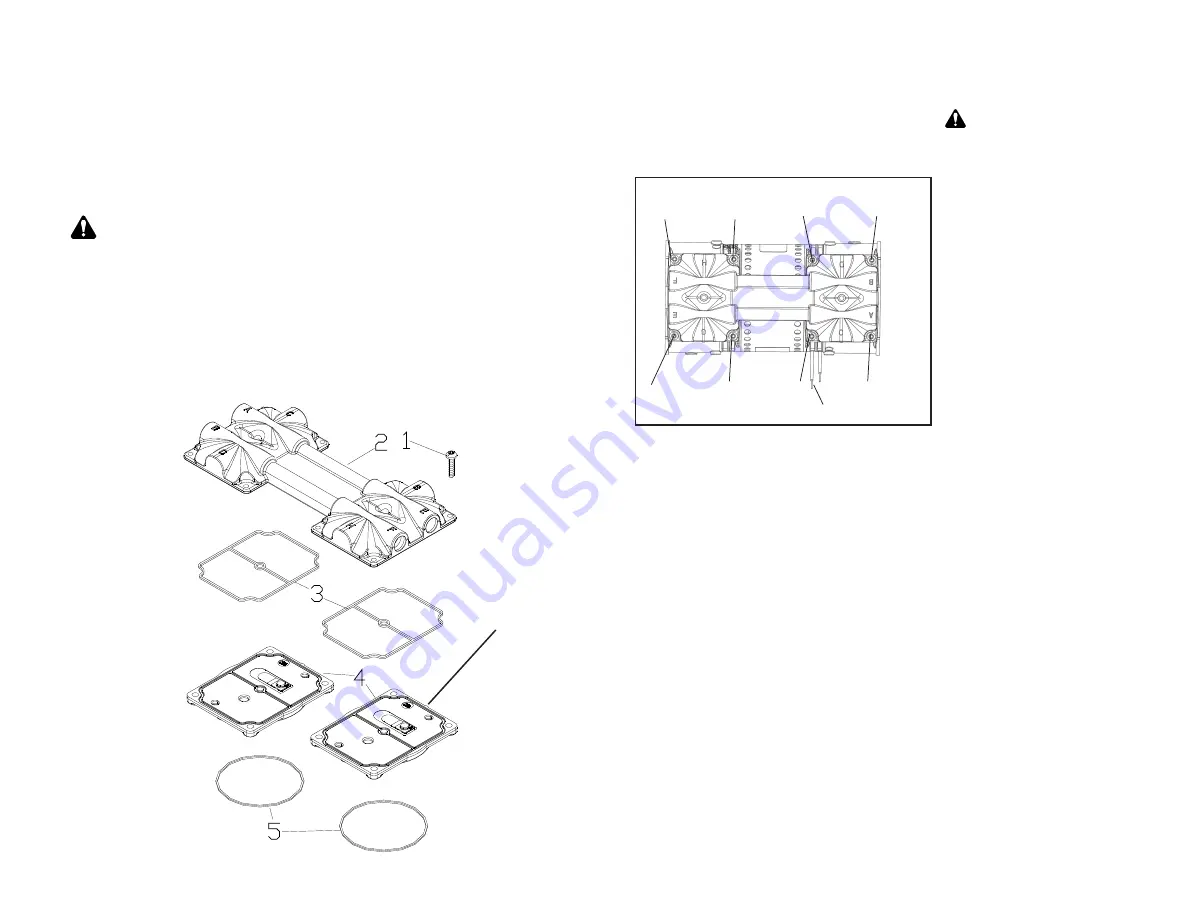

Loosen the 8 head screws (1) and remove the compressor head (2). Note orientation

of head and valve plates for reassembly (very important). Discard head screws.

Caution: Place capacitor off to side leaving it connected to

lead wires.

STEP 3.

Carefully remove the valve plates (4) from the bottom of the head, or cylinder

sleeves

STEP 4.

Remove the head gasket O-rings (3) and discard them. Turn the valve plates over.

Remove the valve plate O-rings (5) and discard them. Note orientation for reassembly.

1

Figure 1

Caution

To avoid property damage

or personal injury, always

try rotating the fan by HAND

prior to connecting the

unit to the power source.

Check for suction at the air

inlet port by placing your

finger over the port as you

turn the fan. You should

feel a slight suction with

each rotation of the fan. If

you don’t feel suction, or if

you feel or hear a thump as

you turn the fan, DO NOT

CONNECT THE UNIT TO A

POWER SOURCE; review

the assembly procedure for

possible error.

Numbers indicate tightening sequence

Power Leads

Head Assembly

5 3 7

1

4

6

2 8

STEP 2.

Place head on the valve plates, making sure the same letter orientation is

as it was before disassembly. Torque the head screws to 55 inch lbs. in a criss-cross

pattern.

STEP 3.

Push the fan guards into the housing until the release tabs “pop” into the

mounting holes in the compressor housing.

6

Note the tabs on

the valve plate

which indicate

exhaust side.