4

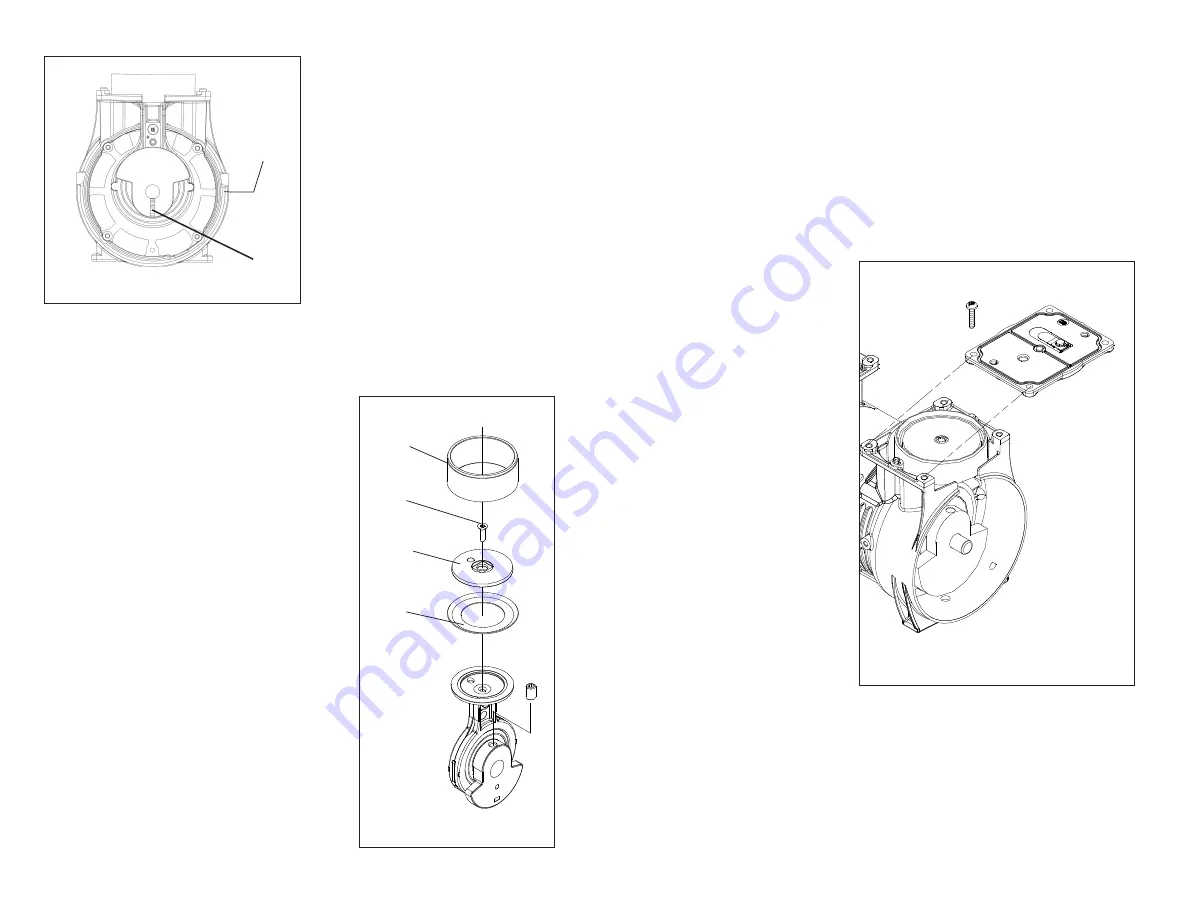

STEP 14

. Rotate the rotor shaft so that flat faces up (12:00). Position piston cup at bot-

tom dead center of cylinder sleeve.

STEP 15.

Slide the connecting rod assembly onto the shaft until the eccentric face

positivly stops against the bearing. Align the eccentric setscrew with the flat of the shaft.

Rotate the eccentric and shaft 90 degrees so the set screw is visable through the access

hole in the housing, and tighten set screw to 125in•lbs.

STEP 16.

Align the flat on the fan with

the flat on the

motor shaft and slide the

fan back onto the motor shaft, making

sure you position the fan clip in the

same orientation as it was before you

removed it. Incorrect orientation of the

fan will not provide adequate cooling of

the compressor.

Figure 7

Hold the sleeve down against the

housing with one hand, and slowly

rotate the fan with the other hand to

ensure all components are lined up

properly. As the piston travels up and

down it will also rock from side to side.

This is a feature of the WOB-L Piston.

Repeat steps 9-16 on the other side of

compressor.

STEP 11

. Insert the 5/32” allen wrench into

the access hole in the compressor hous-

ing. Loosen the set screw 1/4 turn. Rotate

connecting rod to top dead center (180°)

and slide the connecting rod/eccentric

assembly off the shaft and through the

opening in the housing.

3

Eccentric

Set Screw

Access

Hole

Eccentric

Set Screw

Figure 5

STEP 12.

Secure the rod assembly in a fixture.

Remove the sleeve (1 - discard) from the con-

necting rod. Remove the screw (2 - discard )

from the cup retainer (3-retain for reassembly).

Remove the piston cup (4 - discard) and wipe

debris from the top of the connecting rod and

retainer with a clean damp cloth.

STEP 13

. Carefully place new sleeve (1) over

connecting rod top. Place new cup (4) in center

of connecting rod top. Do not damage the cup.

Place retainer (3) on top of cup (counterbore

up), making sure that the cup inside diameter

is seated properly over retaining boss. Note

that the retainer has a locating boss that must

insert into rod top pilot. Drive new retainer screw

to 100 in•lbs. Carefully push sleeve up forming

the cup. Stop pushing the cylinder sleeve up

when the piston cup is positioned midway inside

the sleeve.

1

4

3

2

Figure 6

CHECK OPERATION