2-15

2

START-UP PROCEDURE 2.8

The following start-up procedure should always be

adhered to when starting up a new installation or when

restarting after pump repairs have been made.

1

Fill the hydraulic oil reservoir to the proper level.

( fig. C1878 )

2

Check inlet and pressure hose fittings for proper

tightness prior to starting.

4

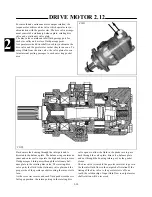

The pump must be filled prior to start-up with fil-

tered oil. Fill the pump by pouring oil into the case drain

port. (fig. C4257 location “F” ) In the case of this loader,

the case drain is filled by gravity from the tank. The fit-

ting should loosen be double checked that there is oil pre-

sent.

5

Disconnect the engine stop solenoid wiring, or

remove the fuse connected to the red wire. (fig. C1887,

C1692)

6

Turn the engine over by engaging the starter. Repeat

this step, turning the engine over in 15 second interval, 5

or 6 times. This will fill the rest of the hydraulic hoses.

7

Reconnect the engine stop solenoid or replace the

fuse.

8

Start the engine and let idle at lowest possible set-

ting.

9

Check for leaks and make adjustments as required.

Do not use your hands to check for leaks while the engine

is operating.

10 Replenish the hydraulic oil reservoir as required. (fig

C1690 fig C1878)

11 Start the engine and increase the rpm to half throttle.

Bring the hydraulic fluid up to operating temperature and

make control adjustments as outline in Section 4.

C4257

C1887

C1690

C1878

C1692

Solenoid wire connector

Reservoir sight gauge

Fuse panel

Internal charge pump model shown

WARNING

This start-up procedure must be made with the

loader securely raised off the ground.

WARNING

Use caution when dealing with hydraulic fluid under

pressure. Escaping fluid under pressure can pene-

trate the skin and cause serious injury.

F