2-34

2

8

Install the adapter fittings to the drive motor.

9

Install the brake lines to the drive motor. (fig. C2082)

10 Install the high pressure drive hoses. (fig. C2074)

11 Clean the final drive housing and inspection cover

thoroughly before sealing the transmission. Apply the

gasket Seal to the transmission. (fig. C2076)

12 Install the inspection cover. When installing the nuts,

do not over tighten. The mounting torque should not

exceed 15 lbs ft. (15 Nm)

14 Start the engine and check for hydraulic leaks. Do

not use your hands to trace hydraulic leaks. Shut off the

engine and inspect each fitting for proper torque.

15 Install the wheels and torque the nuts at 100 to 110 ft

lbs. (136 to 149 Nm.)

16 Install shields and seat, let loader down to ground

and test drive to check performance.

DRIVE MOTOR 2.12

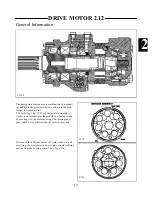

C2076

Apply sealing gasket

C2082

C2074

Brake hoses

Hi - pressure hoses

C1658

Torque the wheel nuts

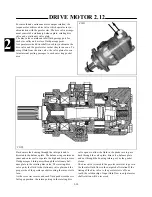

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs

on all open line and ports.

IMPORTANT

Inspect fitting o-rings and flares for marks or dam-

age. Replace if necessary.

IMPORTANT

WARNING

Use caution when dealing with hydraulic fluid under

pressure. Escaping fluid under pressure can pene-

trate the skin and cause serious injury.

WARNING

To prevent personal injury never make repairs to the

hydraulic system while the engine is operating.