4

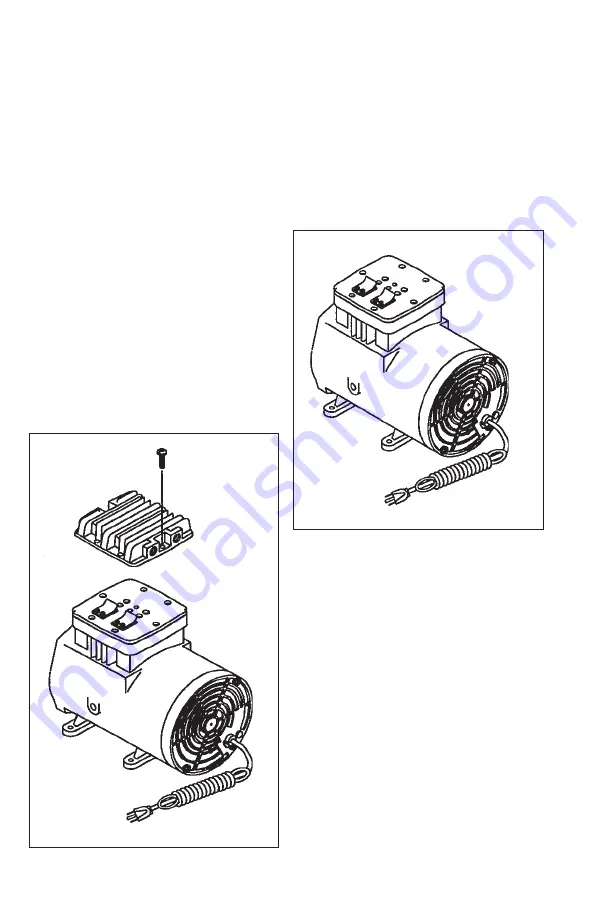

Figure #8

NOTE: The purpose of the following procedure is to correctly position the connecting

rod assembly on the the motor shaft before the Loctite

®

bond has dried.

STEP 4.

Hold the sleeve down against the housing with one hand, and slowly rotate

the eccentric with the other hand. As the piston travels up and down it will also rock

from side to side. This is a feature of the WOB-L Piston. If it rocks from front to rear, the

connecting rod is misaligned on the eccentric. If front to rear rocking is detected, loosen

the connecting rod clamping screw and repeat Steps 1, 2, and 3. If the connecting

rod cannot be properly aligned, contact the nearest service center.

STEP 5.

Install the new O-ring into the

bottom of the valve plate assembly,

seating it firmly into the groove with

your finger or blunt object.

STEP 6.

With the sleeve located and

firmly seated on the housing, replace

the valve plate as shown in Fig. #8.

Make sure the top edge of the cylinder

sleeve locates in the O-ring groove in

the bottom of the valve plate.

Figure #9

STEP 7.

Clean the inside of the head with

a soft clean cloth. Install the new gasket,

seating it firmly in the groove with your

finger or blunt object.

STEP 8.

Place the head on the top of the

valve plate. The exhaust fitting should be

facing the rear of the compressor, and

the smaller cavity inside the head will be

over the curved valve restraints on the

top of the valve plate. Install the 6 head

screws and tighten to 45 in-lbs. NOTE:

The handle, if present, should extend

over the exhaust fitting to provide proper

balance.