2.1

1. The QUICK-KON™ Automated Crimping System is designed be used with Thomas & Betts Press Assembly

(TNB010-press). Refer to the Press Assembly manual for proper installation.

INSTALLATION

2.0

INSTALLING AUTOMATED CRIMPING SYSTEM

1.3

1.2

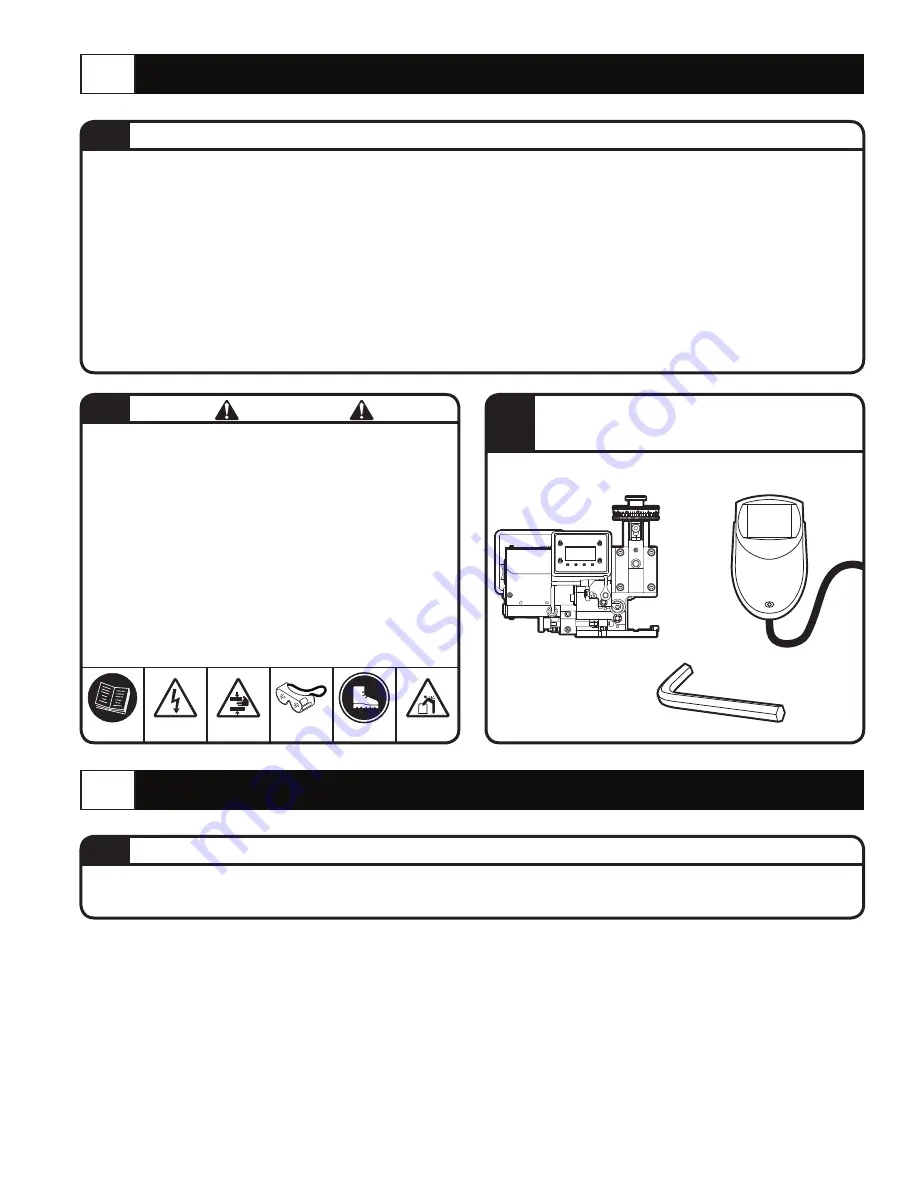

ELECTRIC DIE

M5 HEX WRENCH

POWER SUPPLY

QUICK-KON™ AUTOMATED

CRIMPING SYSTEM INCLUDES

1.1

The QUICK-KON™ Automated Crimping System is a left-to-right side feed applicator which installs in most

industry standard presses, which is comprised of the Electric Die, the Stock Guide Assembly and the Ram Tool.

As a result, one unit can be used to crimp a large variety of terminals - simply through the purchase of additional

tool packs.

Unlike traditional applicators, which use mechanical designs to feed terminals, the Thomas & Betts

®

Electric Die

uses a patented feeding method that electronically performs feeding operations pre-termination. The stepper

motor driven pinch rollers engage the carrier strip and push the terminals into place for crimping. Microprocessor

based electronics, in conjunction with sensors, initiate a feeding cycle on the upward motion of the ram and

control the stepper motor to precisely position the next terminal to be crimped. A feed controller allows the

operator to set feeding parameters electronically. As a result of this superior terminal feeding system, tool packs

are readily accessible and easy to swap…set-up is quick and easy.

DESCRIPTION

4

5

6

1

2

3

WARNING

1. BEFORE USING THE TOOL, CAREFULLY READ

INSTRUCTIONS IN THIS MANUAL.

2. ALWAYS DISCONNECT POWER AND DE-ENERGIZE UNIT

WHILE PERFORMING MAINTENANCE OR TOOLING

CHANGES.

3. WHEN OPERATING THE TOOL NEVER PLACE HANDS OR

OTHER BODY PARTS BETWEEN THE CRIMPING DIES.

4. WEAR EYE PROTECTION WHEN OPERATING OR

PERFORMING MAINTENANCE.

5. WEAR FOOT PROTECTION WHEN MOVING OR

OPERATING THE UNIT.

6. CAUTION IS REQUIRED WHEN MOVING OR LIFTING THE

ELECTRIC DIE ASSEMBLY.

1.0

GENERAL CHARACTERISTICS

TA04864 E Page 2 of 13