- 9 -

1. Application Object

These instructions are applied to all of the PDP monitor, NF-

01DC.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220/230V,

50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

1) After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEAT-

RUN mode)

2) Enter into HEAT-RUN mode

- Select the HEAT-RUN by pressing ADJ button on

Remote Control for adjustment.

- Press the VOL + button in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% full WHITE PATTERN)

3) Set is activated HEAT-RUN without SET TOP BOX or

signal generator in this mode.

[

Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterimage may be occur in the black level part of the

screen.

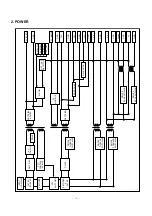

3. POWER PCB Assy Voltage Adjustment

[

Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

3-1. Test Equipment

D.M.M 1EA

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method

(1) Va Adjusment(Address Voltage Adjusment)

1) Connect pin 1 of CN806 or CN811 to (+) jack of D.M.M.

2) After turning the VR351(Va Adj), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/top.(Deviation : ±0.5V)

(2) Vs Adjustment

1) Connect pin 1 of CN803 to (+) jack of D.M.M.

2) After turning the VR551(Vs Adj), voltage of D.M.M adjust

as same as Vs voltage which indicated on label of panel

right/top.(Deviation : ±0.5V)

(3) V-y Adjustment

1) Connect pin 1 of CN802 to (+) jack of D.M.M.

2) After turning the VR751(V-y Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/top.(Deviation : ±0.5V)

(4) Vsetup Adjustment

1) Connect pin 5 of CN802 to (+) jack of D.M.M.

2) After turning the VR651(Vsetup Adj),voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/top.(Deviation : ±0.5V)

(5) 5V Adjustment

1) Connect pin 3 of CN809 to (+) jack of D.M.M.

2) Adjust the voltage data of D.M.M to 5.1V by

turning.(Deviation : ±0.05V)

(6) STBY-5V Adjustment

1) Connect pin 3 of CN808 to (+) jack of D.M.M.

2) Check the voltage(5V) of D.M.M.

3) Adjust the voltage data of D.M.M so that voltage data of

D.M.M is 5V.(Deviation : ±0.05V)

ADJUSTMENT INSTRUCTIONS

Vs

Va CTL

- Vy CTL

VR751

Vsetup CTL

VR651

- Vy

Vsetup

Vs

- Vy CTL

VR751

Vsetup CTL

VR651

- Vy

Vsetup

Va

CN811

CN809

CN808

5V

CN806

CN802

CN803

STBY 5V

VR 351

Va CTL

VR 253

5V

VR 151

STBY 5V

Va CTL

VR 551

Vs CTL

<Fig 1> Connection Diagram of Power Adjustment for Measuring

Refer to Typical Voltage

Va

Vs

Vy

Vsetup

60 ~ 75V

170 ~ 185V

-60 ~ -90V

210 ~ 240V

Summary of Contents for 42WM02L

Page 16: ...MEMO 15...

Page 19: ...P N 3854VA0100B S1 1 2 2002 03 05...

Page 20: ...P N 3854VA0100B S1 2 2 2002 03 05...