ITC222 Geometry & Convergence Procedures

25

future additional screen sizes based on the ITC222 may be calculated using the previous formula.

40": 17 9/16"

52": 22 11/16"

56": 24 3/8"

61": 26 11/16"

40": 8"

52": 10 5/8"

56": 11 1/8"

61": 12 3/16"

40": 8"

52": 10 5/8"

56": 11 1/8"

61": 12 3/16"

40": 16"

52": 21"

56": 22 1/4"

61": 24 3/8"

40": 16"

52": 21"

56": 22 1/4"

61": 24 3/8"

40": 9 13/16"

52": 12 13/16"

56": 13 11/16"

61": 15"

40": 5 5/16"

52": 7"

56": 7 3/8"

61": 8 1/8"

40": 5 5/16"

52": 7"

56": 7 3/8"

61": 8 1/8"

40": 8 13/16"

52": 11 1/4"

56": 12 3/8"

61": 13 1/2"

40": 8 13/16"

52": 11 1/4"

56": 12 3/8"

61": 13 1/2"

H

ORIZONTAL

& V

ERTICAL

S

TRINGS

Horizontal strings actually measure the vertical dimensions. Vertical strings measure the horizontal

dimensions. Do not confuse the dimensions. The middle dimensions are for the CL and are 1/2

the full screen width or height. Due to screen frame variations, use the dimensions from your own

measurements to string the centerlines!

The other dimensions are measurements away from the

center lines!

Once the tape strips are marked in the proper places, simply cut strings and drape

them between the marks on the frame and secure them with additional masking tape. The final

template should appear similar to the diagram.

L

EVEL

2 C

ONVERGENCE

A

LIGNMENT

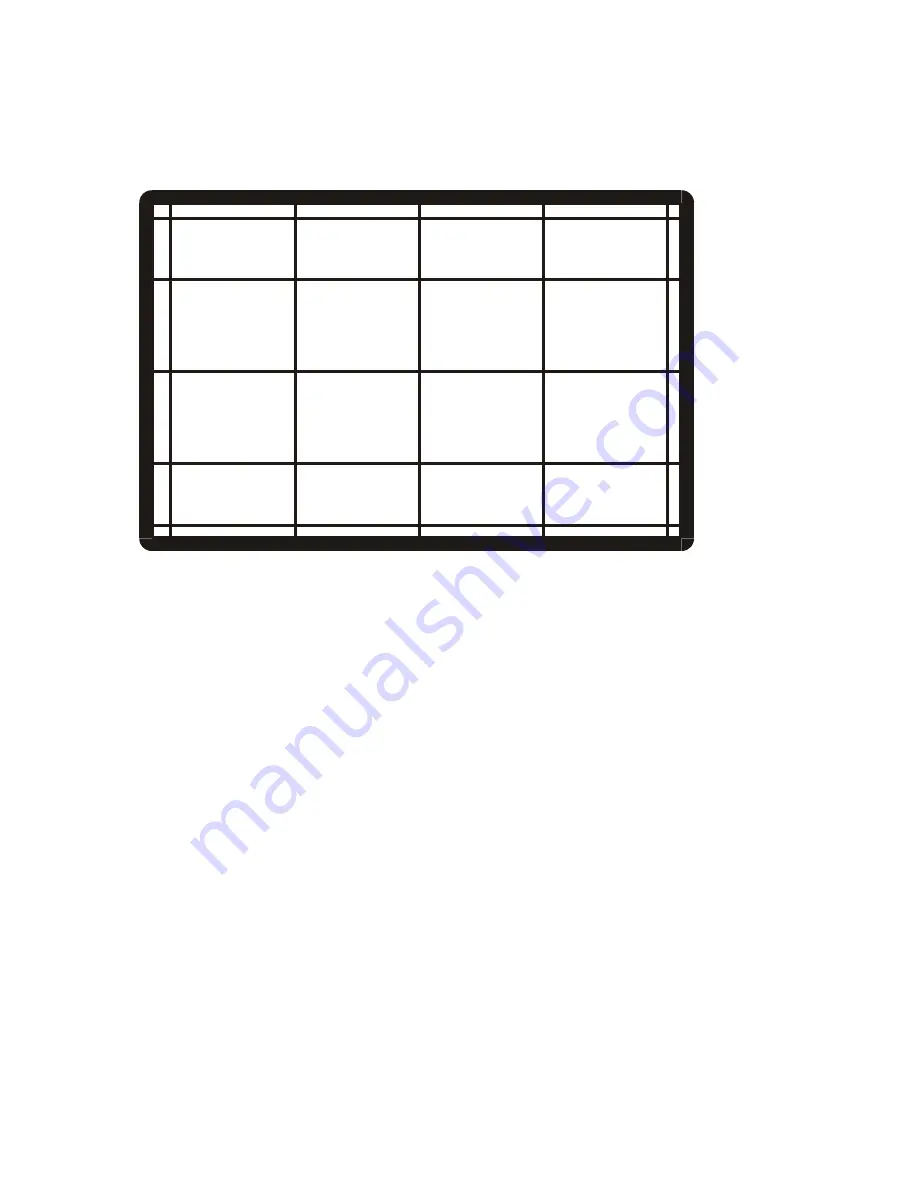

Remember all geometry alignment must be done prior to any convergence procedures. Level 2 is

the highest level of adjustment recommended and should be used to speed up convergence

procedures when all three colors must be redone due to SSB module replacement or if all three

CRT’s must be replaced. Using the string template and placing the level 2 alignment points at the

exact centers of the string intersections, horizontal and vertical linearity and uniformity for points

between the template intersections will be calculated by the convergence microprocessor. The

Level 2 pattern only provides the 25 points shown. Pressing the “2” button on the remote control

moves the alignment position in a specific order around the grid. All 195 alignment points are

adjusted by the microprocessor in relation to each other as the cursor moves to the next point.

Therefore when moving one of the 25 alignment points in Level 2, if there needs to be more than

1/2” of movement it is good practice to only move the point about 1/2 of the necessary distance on

the first pass. That will increase the accuracy of the interpolation being done by the microprocessor.

It is recommended when making adjustments the technician assume at least three full passes around