OPERATION

Final Check List before Operation

1. Have all packing materials and tape been removed from the interior and

exterior of the ice maker?

2. Did you clean the ice storage bin?

3. Have the installation instructions been followed, including connecting the

machine to water and electricity?

4. Has the machine been leveled?

5. Is the ice maker in a site where the ambient temperature is between 45°F

(7°C) and 110°F (43°C) and the water temperature between 41°F (5°C) and

90°F

(

32°C) all year- round?

6. Has the water supply pressure been checked to ensure a minimum of 15

psig with a static pressure not to exceed 80 psig?

7. Is there a clearance of at least 4” (102mm) at the rear, and 1” (25 mm) at top

and sides for proper air circulation?

8. Has the power supply voltage been checked or tested against the

nameplate rating?And has proper grounding been installed in the ice maker?

9. Is the ice maker plugged in?

10.Have you turned on the main water supply and tap?

11.Have you checked for leaks at all water supply connections?

Operating method

1. Turn on the water tap, let the water trough fill, then press

the ON/OFF button

on

the front

panel. The ice maker will start working automatically.

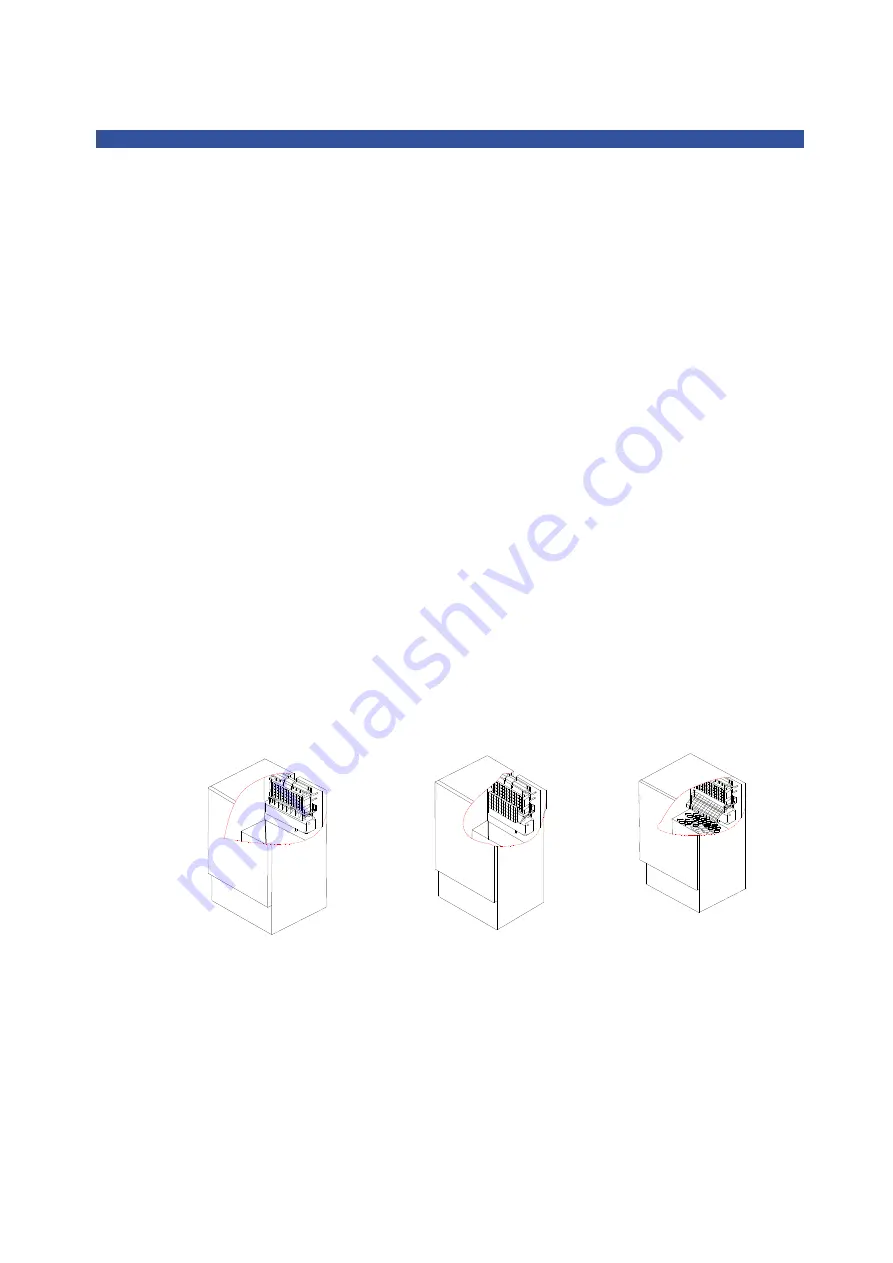

2. After 3 minutes, the machine will automatically go to the ice-making stage,

and the sound of water flowing will be heard.

3. When the batch of ice has been fully formed

,

ice will automatically be

harvested to the

Bin full stage

Ice making stage

Ice harvest stage

16