Scanner

operation

To enable wireless data transfer from Drake to a network computer via a local

Wi-Fi connection, first plug in a USB Wi-Fi adapter. An indicator will appear

in the top right corner of the screen (an antenna with a line through it). This

indicates that the Wi-Fi adapter is plugged in, but not yet connected to the

local network. A list of available Wi-Fi connections can be found by selecting

the appropriate option on the side panel from the main screen.

After connecting, this network will be saved and you will not need to enter

your credentials again in the future. This network will now be first in the list

of networks and when connected, an indicator signal strength will appear in

the status bar.

* Aside from a Wi-Fi USB adapter, you can also be using an Ethernet USB adapter to

connect to a local network.

Find the scanner under “Network” on any computer that is also connected to

the same network. Look for a device called “THOR” and after transferring the

data from the scanner, look for it in a folder by the name of “Scans”. For quick

access, press WIN+R: \\THOR\Scans and create a shortcut to this folder.

* Data transfer speeds over Wi-Fi depends on the type of network equipment you

have installed.

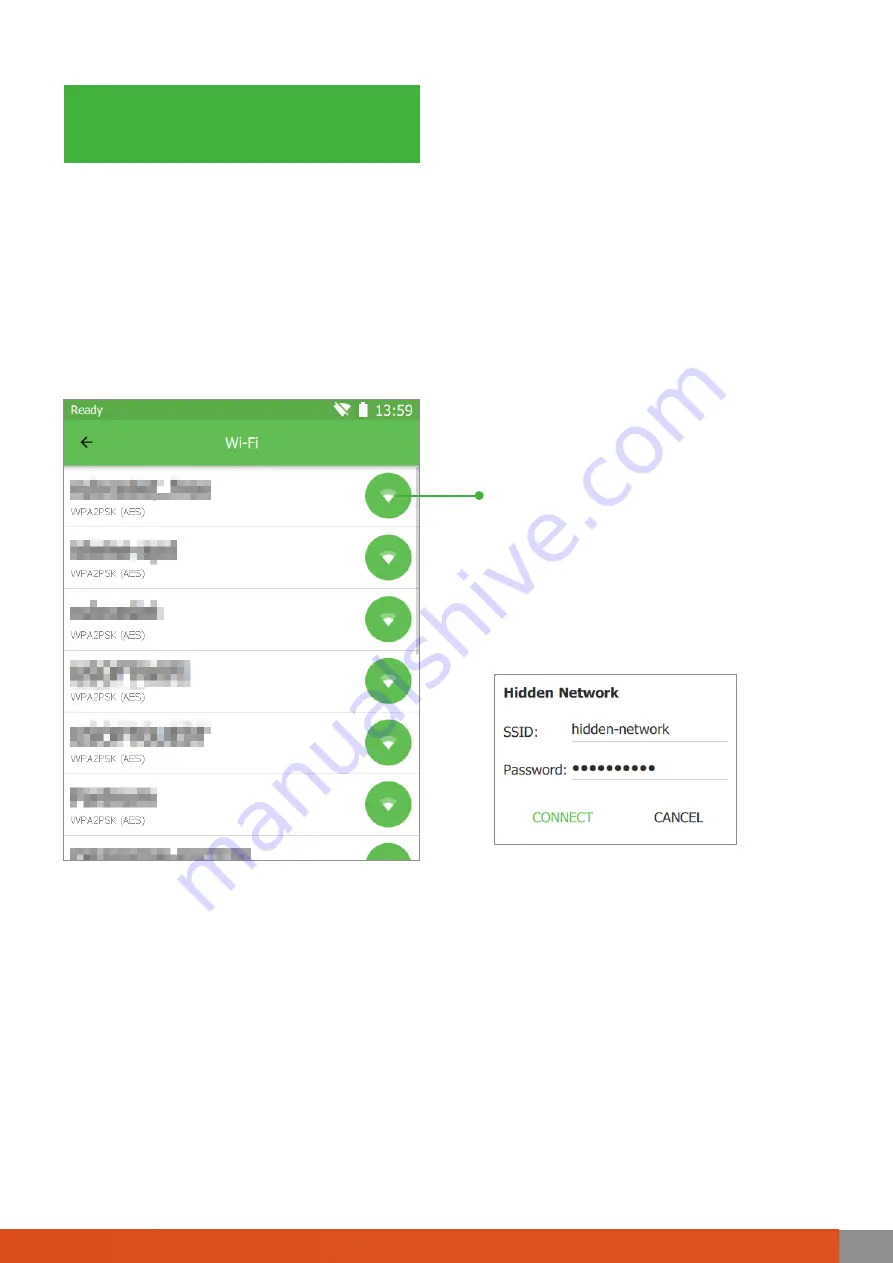

Choose the network you would like to

connect to from the list. A pop-up dialog box

will prompt you to enter the Wi-Fi password.

Press

CONNECT

. If the network is hidden,

scroll to the bottom of the list and select

Hidden Network

. Enter the name of the

network (SSID) and password and press

CONNECT

.

Wi-Fi Settings

DRAKE

67

Summary of Contents for Calibry

Page 1: ...3D scanner User manual...

Page 2: ......

Page 24: ......

Page 25: ...3D scanner Software manual...

Page 55: ...3D scanner 53...

Page 58: ......

Page 59: ...User manual DRAKE...

Page 74: ...72 Drake User manual 72...