Rev 19 Oct 2020

Page 19

Chapter 4 Operation

4.4 Recommended Scanning Angles

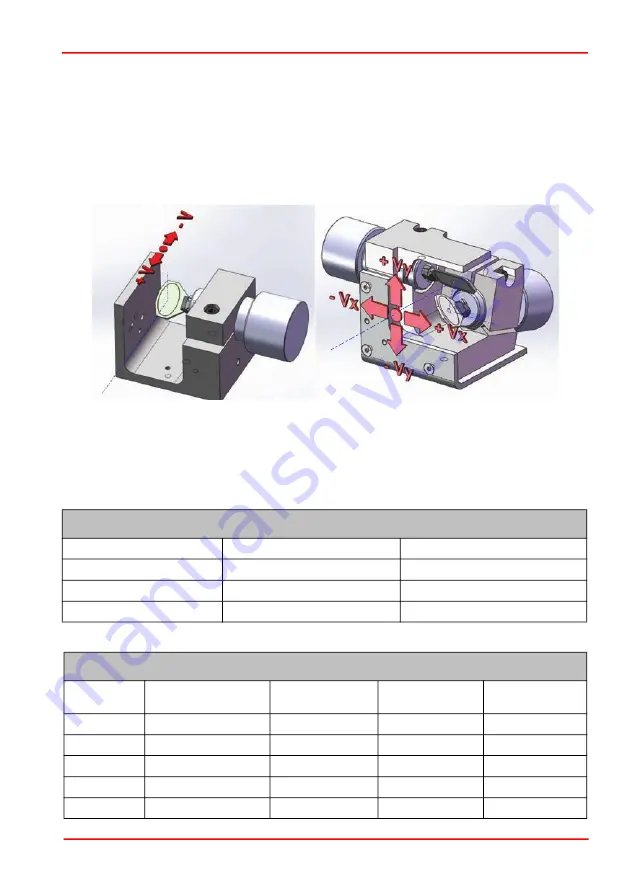

Although the maximum mechanical scan angle is stated as ±20° in Section 3.2.5. the

maximum angle achievable without interference is dependent upon a number of

conditions. Firstly, the larger the diameter of the input laser beam, the smaller the

achievable scanning angle. Secondly, the applied input voltage causes the laser

beam to move away from the center of the mirrors. The larger the input voltage then

the greater the movement from the center, as shown below.

Lastly, on dual-axis systems, there is an offset alignment between the X and Y axis

mirrors that also limits the scan angle.

The table below gives recommended scanning angles for various beam diameters.

GVS011, GVS111, GVS211, GVS311 and GVS411

Input Beam Diameter

Mechanical Scan Angle

Optical Scan Angle

7 mm and less

± 20°

± 40°

8 mm

+ 20°, -16°

+ 40°, -32°

10 mm

+ 20°, -8°

+ 40°, -16°

GVS012, GVS112, GVS212, GVS312 and GVS412

Input Beam

Diameter

Mechanical

Scan Angle X

Optical

Scan Angle X

Mechanical

Scan Angle Y

Optical

Scan Angle Y

2 mm

± 15.5°

±31°

± 20°

± 40°

4 mm

± 13.5°

±27°

± 20°

± 40°

6 mm

± 11.5°

±23°

+ 20°, - 17.5°

+ 40°, - 35°

8 mm

± 10°

± 20°

± 15°

± 30°

10 mm

± 8.5°

± 17°

+ 5°, -13°

+ 10°, -26°

Input Axis

Output Axis

Input Axis

Output

Axis

Summary of Contents for GVS011

Page 40: ...www thorlabs com ...