LSK-GG

Chapter 7: NI PCIe 6363 Card Schematic

Rev A, November 11, 2016

Page 11

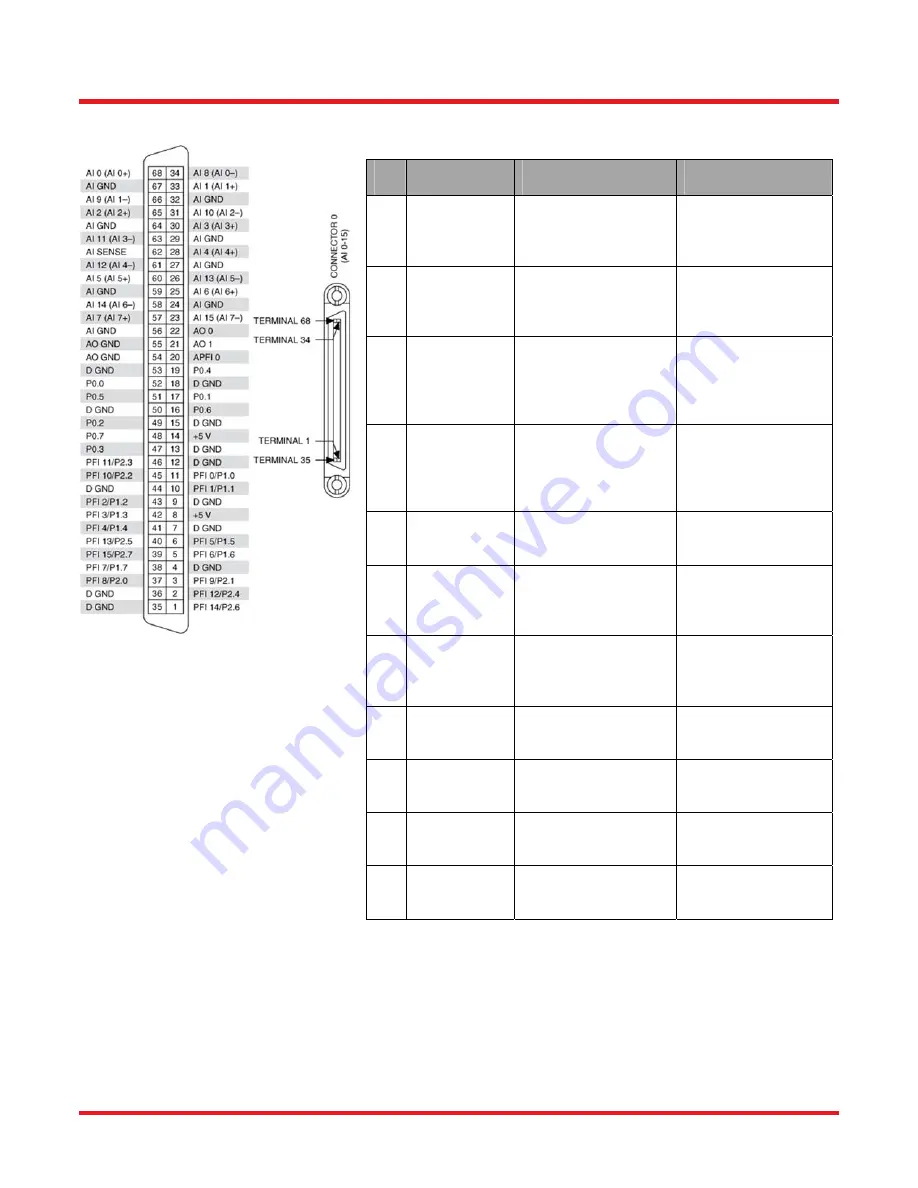

Chapter 7

NI PCIe 6363 Card Schematic

Figure 4

NI PCIe 6363 Pinout

Pin Signal Name

Description

Characteristics

21

Y Position IN

Position In signal

200 kΩ input

impedance, ± 10 V

input

22

X Position IN

Position In signal

200 kΩ input

impedance, ± 10 V

input

26

X Velocity

Voltage signal is

proportional to the

velocity of the

scanner

2 kΩ output

impedance

28

Y Velocity

Voltage signal is

proportional to the

velocity of the

scanner

2 kΩ output

impedance

30

X Position

OUT

Position Out signal

2 kΩ output

impedance, ± 4 V

38

Y Fault

Pulled down to

ground when the fault

detector trips

4.75 kΩ output

impedance to 12 V

CMOS logic

46

X Fault

Pulled down to

ground when the fault

detector trips

4.75 kΩ output

impedance to 12 V

CMOS logic

54

Ground

Ground return for

user signals

GND

57

X Current

Current monitor

2 kΩ output

impedance

60

Y Current

Current monitor

2 kΩ output

impedance

65

Y Position

OUT

Position Out signal

2 kΩ output

impedance, ± 4 V