Page 14

MLS203 Series XY Scanning Stage

The values quoted above are the maximum values recommended to avoid over

current errors. These values are a guideline only, and depending on the shape of the

mass and the velocities used, these values may require further adjustment,

particularly if the stages are mounted in an XY configuration.

4.4 Position Error Messages.

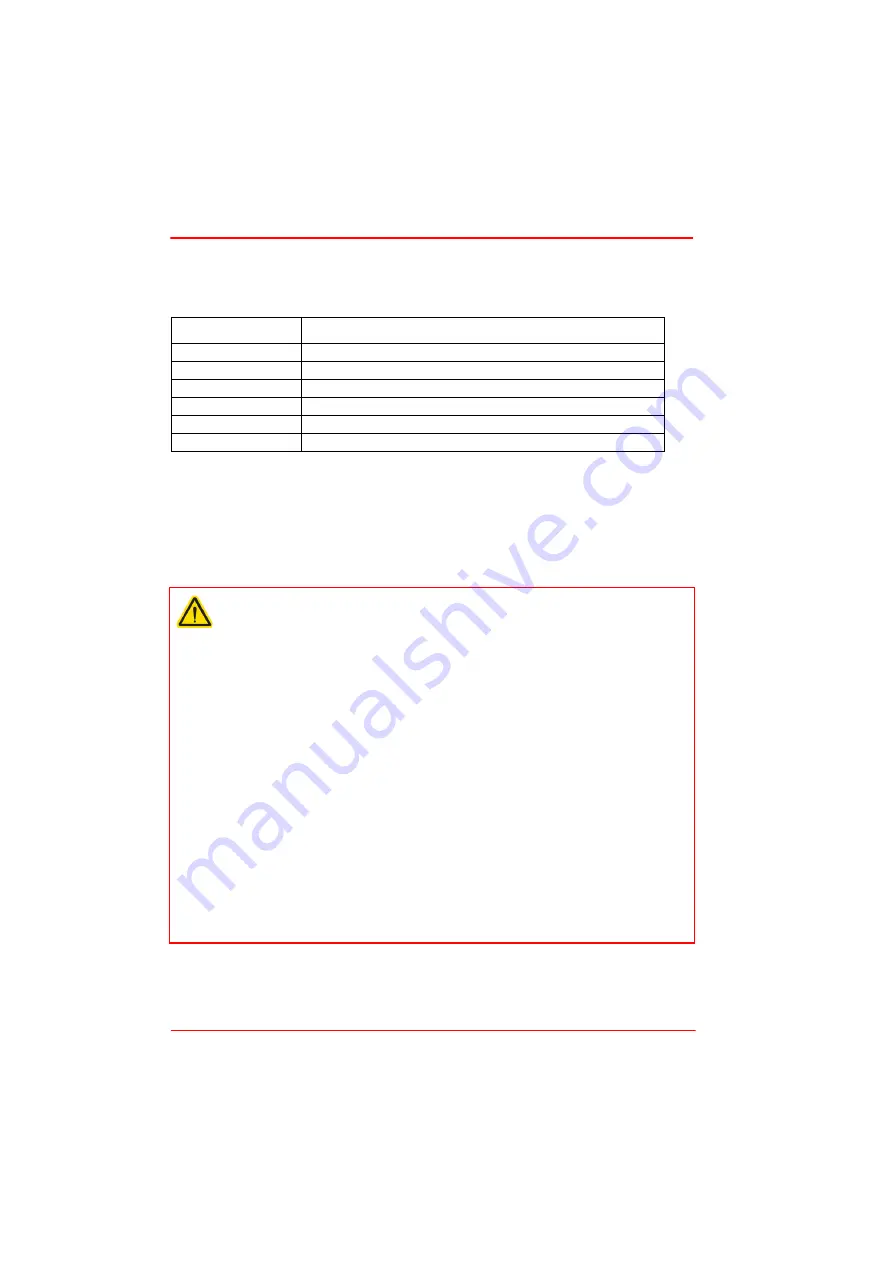

Table 4.2 Load vs Maximum acceleration recommendations

Load (g)

Approximate Max Acceleration (mm/s²)

0

5000

125

2400

250

1550

500

925

750

650

900

500

Caution

The maximum velocity at which the encoder can operate is approximately 400

mm/sec. Above this speed, encoder pulses may be lost and, as a result, the

position readout becomes incorrect. This renders normal operation impossible

because phase commutation of the motor is also based on the encoder reading.

When the stage is controlled by the BBD20x controller, the maximum velocity

is limited to safe values. However, if the output is disabled (with the controller

connected and monitoring the position) and the stage is moved manually at

high speeds, it is possible to exceed this limit. If the BBD20x controller is

subsequently used again to move the stage, the incorrect encoder reading will

cause incorrect operation, often resulting in sudden uncontrolled moves. It is

therefore important not to move the stage excessively quickly when it is moved

manually.

The BBD controller has fault monitoring to detect the loss of encoder pulses. If

this fault occurs, an error message will be generated and the controller must be

powered down and re-started so that correct phasing and commutation can be

established.

If this fault occurs when the stage is being controlled via the MJC001 joystick,

in the absence of a PC, the red LED on the joystick console is lit, and all

operation is suspended until the controller is shut down and rebooted.