Page 6

22115-D02

MLS203 Series XY Scanning Stage

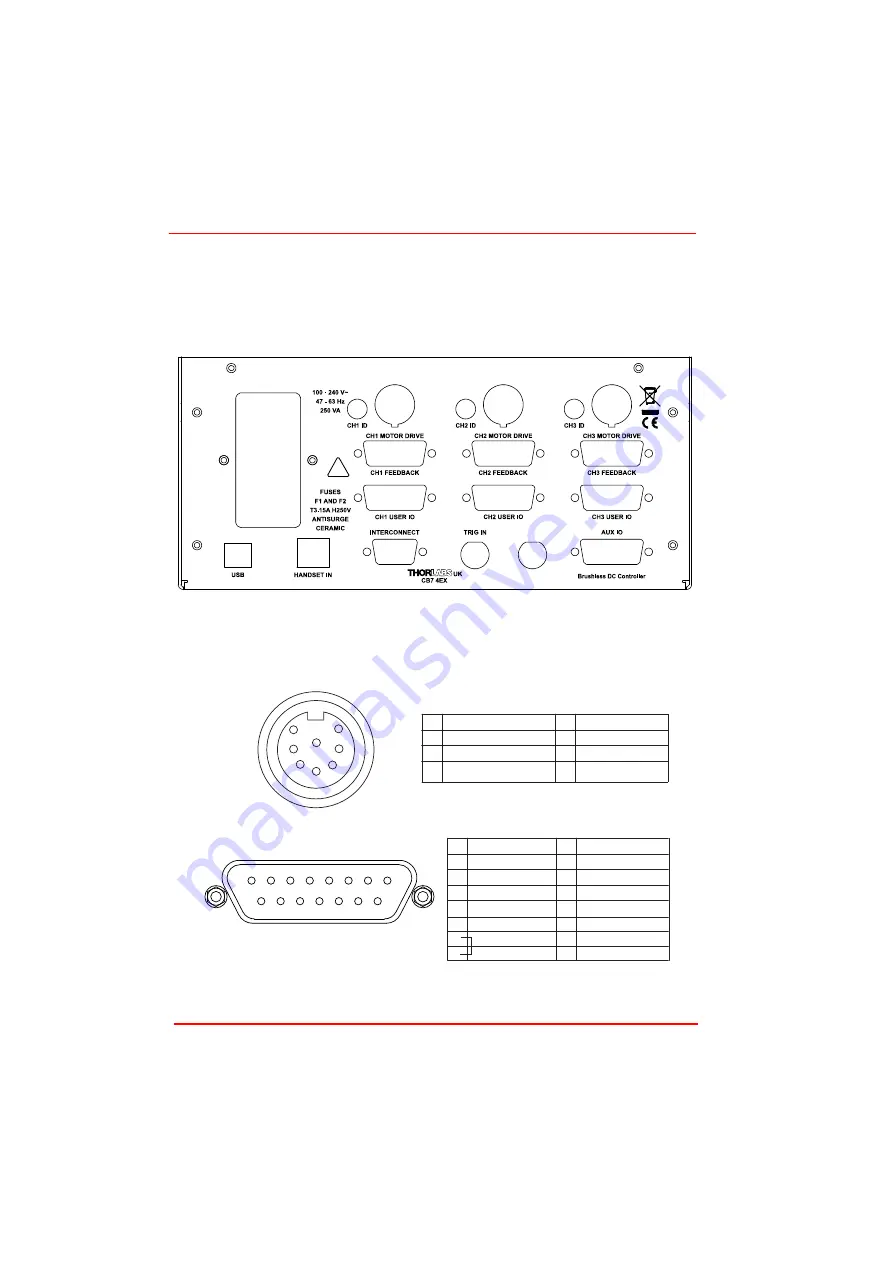

3.3 Electrical Connections

The stage must be driven by a Thorlabs BBD series controller. Connect the motor

leads to the MOTOR DRIVE connectors, and the encoder feedback leads to the

FEEDBACK connectors. Ensure that the motor drive and feedback leads for each

motor are connected to the correct channel.

Fig. 3.3 Electrical connections

Pin out information for the motor drive and encoder feedback connectors on the motor

flying leads is detailed below.

Fig. 3.4 Motor Drive and Feedback Flying Lead Pin Out Details

TRIG OUT

!

1 Motor Phase V

2 GND

3 Thermistor (not used)

4 Motor Phase U

5 Stage ID

6 GND

7 Motor Phase W

8 Enable

1

2 GND

3

4 Enc Index -

5 QB -

6 QA -

7 5 V

8 5 V

9 GND

10 Limit

11 Limit Switch -

12 Enc Index +

13 QB +

14 QA +

15 x

3

5

8

2

6

4

1

7

8

7

6

5

4

3

2

1

15

14

13

12

11

10

9

MOTOR DRIVE

ENCODER FEEDBACK