GPX3800 and GPX3850 Glass Processors

Chapter 3: Description

Rev B, July 24, 2018

Page 11

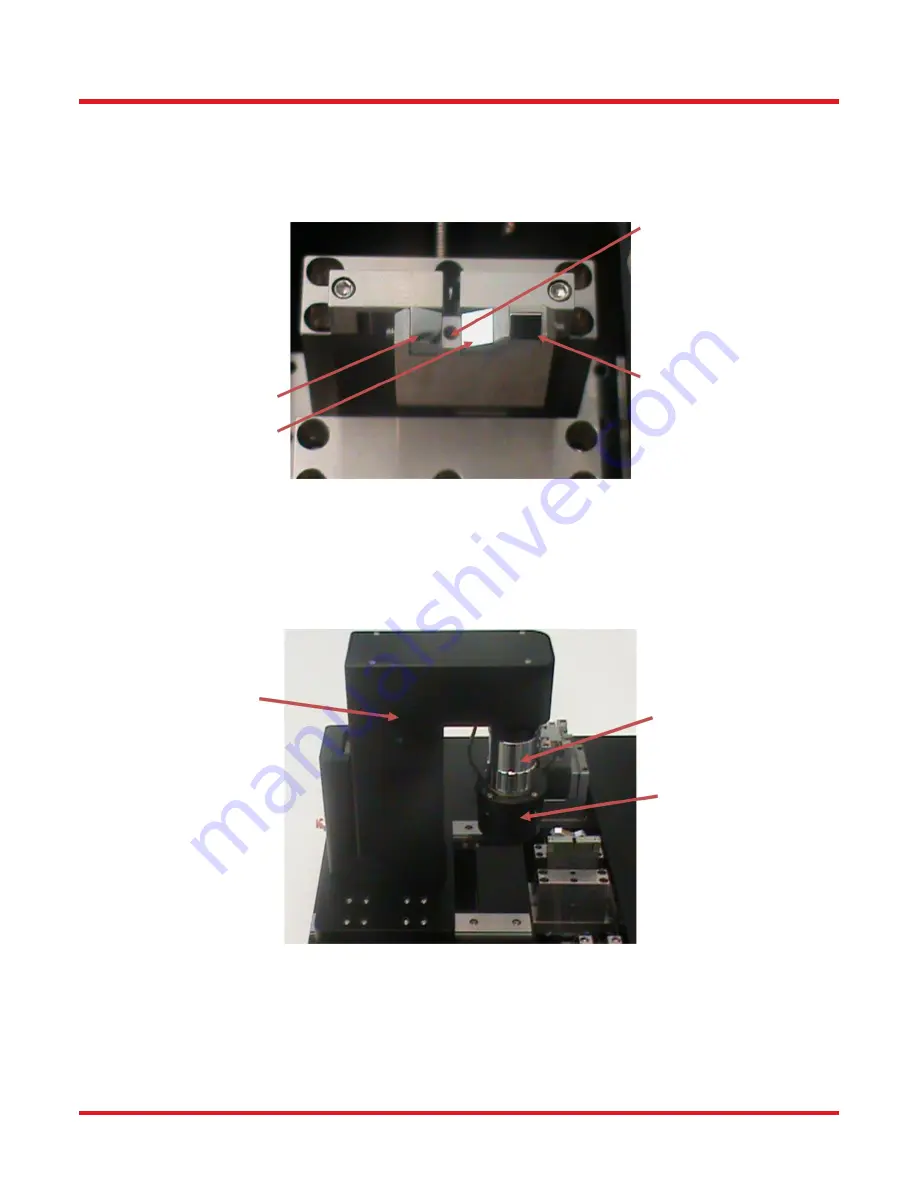

3.4.4. Mirror Tower

The mirror tower has two sets of mirrors and an LED. The first set of mirrors makes it possible to view the sides of

the fiber. They provide the “Front View” and “Back View”. The second set of mirrors makes it possible to view the

ends of the fibers. The LED provides backlighting when viewing the fiber directly in center view. The Mirror Tower

moves in the X-axis to provide the ability to view both the side view and end view of the fibers.

Mirror Tower

3.4.5. Imaging System

The GPX3800 and GPX3850 workstations come with an automated camera assembly used for imaging the fibers.

This tower can be moved forwards and backwards as well as up and down. It is equipped with a ring illuminator

that provides backlighting for the front and back views of the fiber. The camera objective may be replaced if a

larger (or smaller) field of view is desired.

Imaging Camera Assembly

Center View LED

End-View Mirror

Front View Mirror

Back View Mirror

Camera Objective

Ring Illuminator

Camera Tower