2

Item

Quantity

Description

1

1

RTV Tube

2

1

Power Connection Boot

3

2

Conductor Wire Pins

4

1

Braid Wire Pin

5

1

Ground Sleeve

6

1

End Cap

7

1

Tape Strip (PETK-3-ZT only)

8

1

Grommet (PETK-3-ZT only)

9

1

End Termination Caution Label

Tools Required . . .

Certifi cations/Approvals . . .

1725 II 2 GD Ex db eb IIC T5-T6, Ex tb IIIC T100°C-T85°C FM10ATEX0058X

IP66 -60°C

Ta

+50°C T5, 100°C; -60°C

Ta

+40°C T6, 85°C

Ordinary & Hazardous Locations

FMG 10.0022X Ex db eb IIC T5-T6, Ex tb IIIC T100°C-T85°C

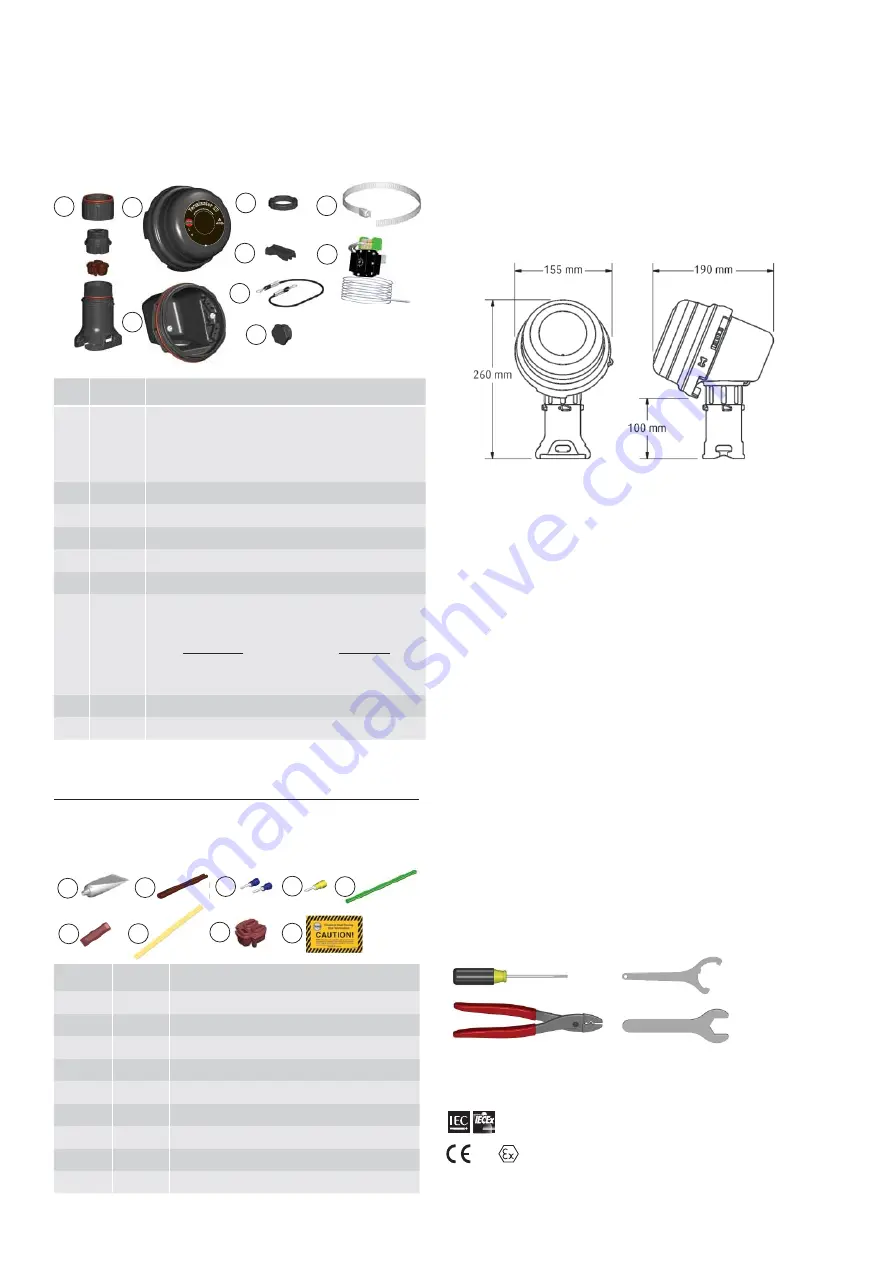

Kit Contents . . .

1

2

6

4

3

8

5

7

9

Dimensions . . .

Terminator

TM

ZT-P-XP

INSTALLATION PROCEDURES

1

2

6

4

3

8

5

7

9

Item

Quantity

Description

1

1

Expediter Assembly

Support Cap with O-Ring

Threaded Grommet Compressor

Grommet

Support Base with O-Ring

2

1

Junction Box Lid

3

1

Junction Box Base with O-Ring and M25 Dust Cap

4

1

Nut

5

1

Banding

6

1

Banding Guide

7

1

Thermostat w/ Terminal Blocks

(Refer to terminal specifi cations for maximum allowable wire size)

Thermostat Type

Control Range

ZT-C-100 0

°

C to +100

°

C

ZT-C-200 0

°

C to +200

°

C

8

1

Junction Box Cord

9

2

Blind Plug

Terminator-LN-Tool

(order separately)

3 mm

8 mm

28 mm

Warnings

. . .

• Due to the risk of electrical shock, arcing and fi re caused

by product damage or improper usage, installation or

maintenance, a ground-fault protection device is required.

• Installation must comply with Thermon requirements

(including form PN 50207U for Ex systems) and be installed

in accordance with the regulations as per the norm EN IEC

60079-14 for hazardous areas (where applicable), or any

other applicable national and local codes.

• Component approvals and performance ratings are based

on the use of Thermon specifi ed parts only.

• De-energize all power sources before opening enclosure.

• Avoid electrostatic charge. Clean only with a damp cloth.

• Keep ends of heating cable and kit components dry before

and during installation.

• Minimum bending radius of heating cable is 32 mm (except

HPT is 57 mm and FP is 19 mm).

• Individuals installing these products are responsible for

complying with all applicable safety and health guidelines.

Proper Personal Protective Equipment (PPE) should be

utilized during installation. Contact Thermon if you have any

additional questions.

Ter

minato

r Z

T

IP66

-45

°

C

Ta

+

55

°

C

For

use

as an adjustable co

ntro

l th

erm

os

ta

t

wi

th

The

rmon heating

ca

ble

s

ys

te

m

s

II 2 G & D E

Ex ed I

I C T5

0539

DEMKO 02A

TEX132552X

17

2

5

II

2 G

D E

x db e

b IIC T5-T6, Ex tb IIIC T

100

°C-

T8

5°

C,

F

M

1

0A

TE

X

0

0

5

8

X

IEC

Ex F

MG 1

0.0022X

Ex db

eb I

IC T

5-T

6,

Ex

tb

II

IC

T

10

0

°C

-T

8

5

°C

PN 27656

Te

rm

inator Z

T

Fo

r u

se

as

an

adj

ustable

control/lim

iter t

her

m

os

tat

IP

6

6

-6

0°

C

≤

Ta

≤

+50

°C T5, 100°C; -60°C

≤

Ta

≤

+4

0°

C

T6

, 8

5

°C

Terminator has additional hazardous area approvals including:

• GGTN • Kazakhstan

Order Separately . . .

PETK Power and End Termination Kits (per cable)

PETK-1

for RSX, VSX, BSX

PETK-2

for KSX, HTSX

PETK-3-ZT for HPT, FP

The following installation procedures are suggested guidelines

for the installation of the Terminator ZT-P-XP Kit.

Receiving, Storing and Handling . . .

1. Inspect materials for damage incurred during shipping.

2. Report damages to the carrier for settlement.

3. Identify parts against the packing list to ensure the proper

type and quantity has been received.

4. Store in a dry location.