THRUSH AIRCRAFT INC – MODEL S2R R1340

AIRCRAFT MAINTENANCE MANUAL

5-10

Effective: 01/01/08

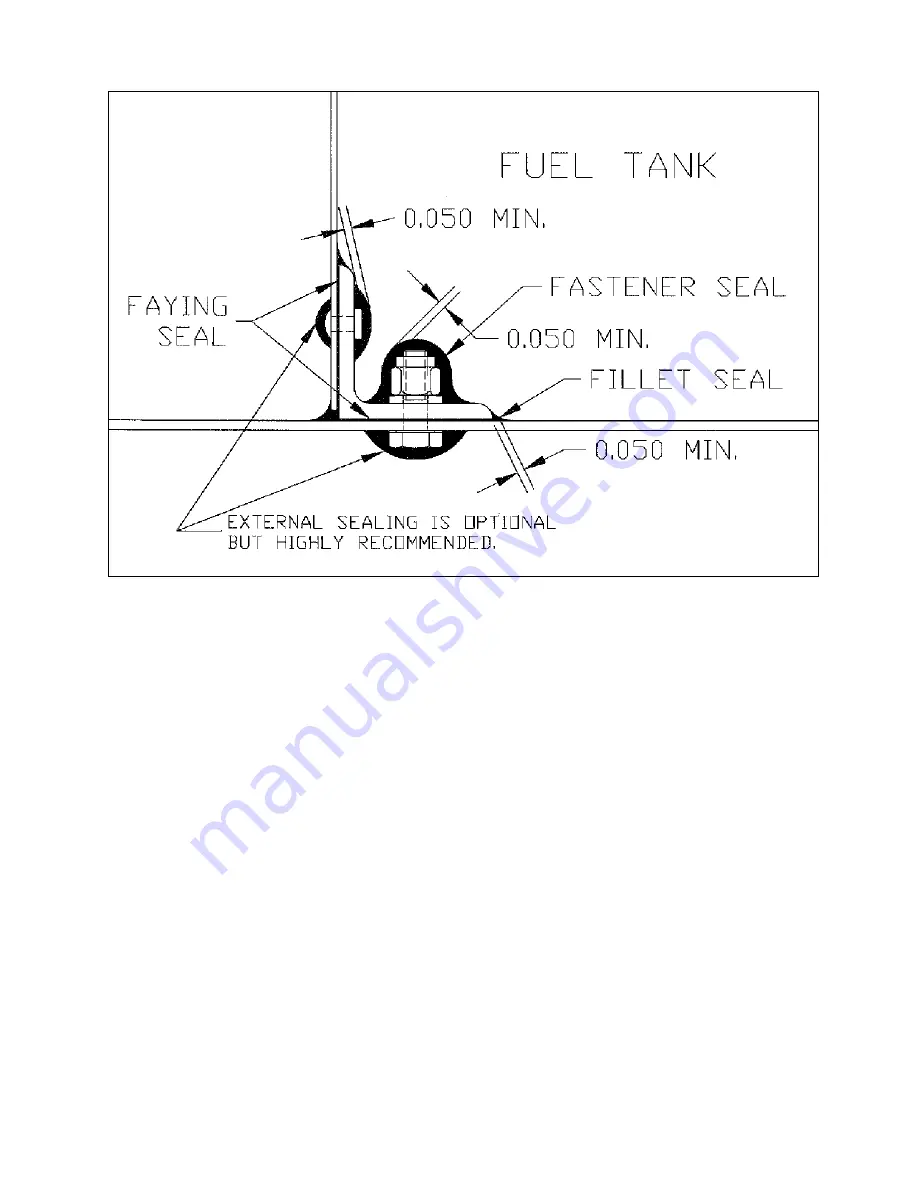

Figure 5-4: Proper Application of Fuel Proof Sealant

When working with fuel tank sealer,

cleanliness is mandatory. Something as

simple as a fingerprint or a piece of lint

can result in a fuel tank leak down the

road. Rule one is to get all the cutting,

drilling, grinding, etc. out of the way

before you start trying to seal. Having to

add a hole after sealing has begun is a

recipe for a leak. Deburr all holes and

edges and clean out all shavings.

Faying seals involve a layer of “B” type

sealant between mating surfaces.

Sealant is spread on both mating

surfaces before joining. If working on

mating surfaces that are pried apart, use

a pressure applicator to be sure sealant

gets all the way between the mating

surfaces where they are still attached.

When the fasteners are tightened,

starting at one end and working to the

other, the faying sealant is squeezed out

along the edges. If a small bead does

not squeeze out, not enough sealant was

used. Ideally the faying seal should end

up .015” or about 1/64” thick.

Fillet seals are continuous lines of

sealant along the joints between two

parts. The bead squeezed out from the

faying seal is a good start, and may be

sufficient when formed into a fillet. If the

bead material is not enough to get the

coverage thickness specified in Figure 5-

4, add more “B” sealant. Use a tool or a

latex gloved finger for smoothing, not a

bare finger. Do not try to clean up

excess sealant with solvent.

LEAK SEALING

Determine the approximate location of

the leak by visual inspection through the

cover plates in the lower surface of the

wing. After leak area is determined,

drain all fuel from affected tank. See

Section 2 for defueling procedures.