THRUSH AIRCRAFT, INC – MODEL S2R R1340

AIRCRAFT MAINTENANCE MANUAL

Effective: 01/01/08

5-15

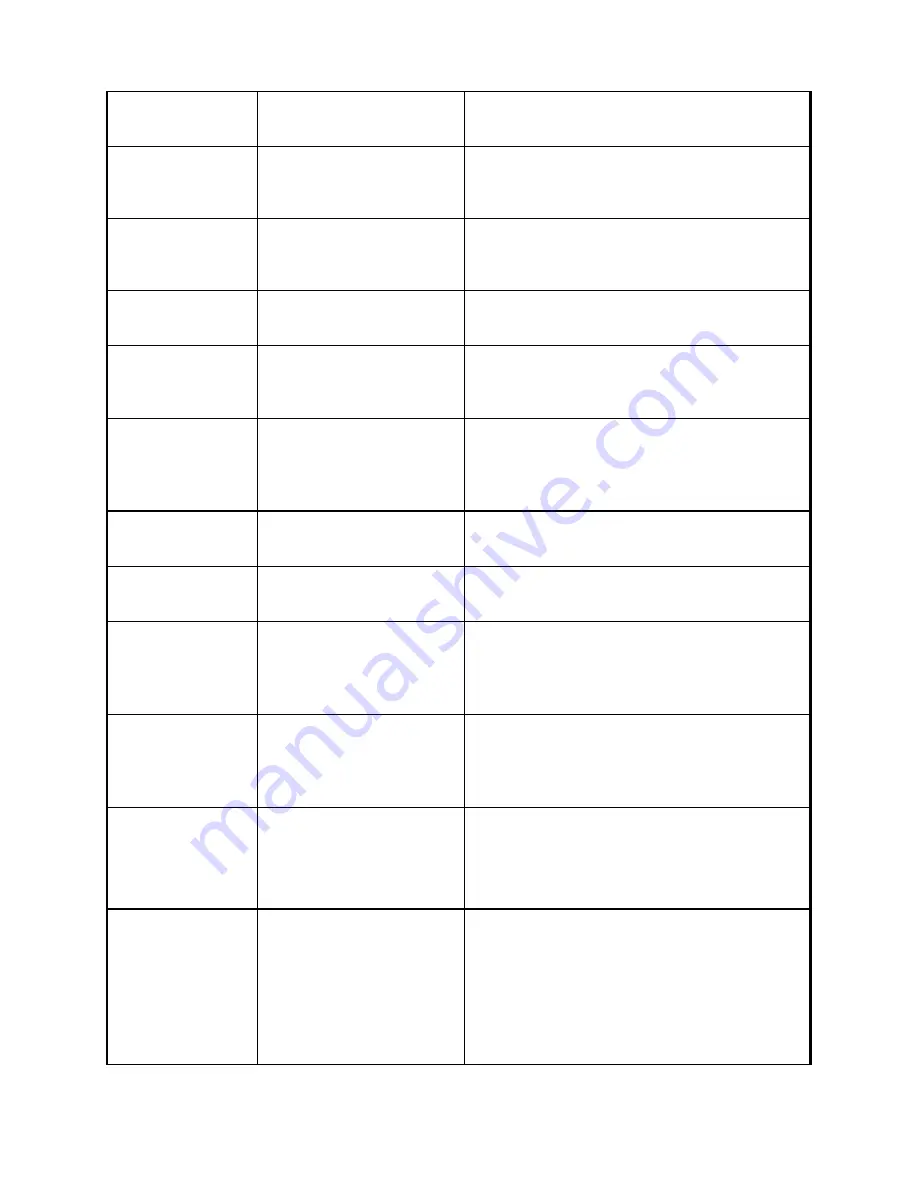

PROBLEM PROBABLE

CAUSE

REMEDY

No fuel flow to

engine.

(Continued)

Fuel line plugged.

Starting at fuel pump inlet, disconnect

fuel lines successively until plugged line

is located. Clean out or replace fuel line.

Fuel starvation

after starting.

Partial fuel flow from the

preceding causes.

Use the preceding isolation procedures,

checking for sufficient rate of flow. Using

the preceding remedies.

Malfunction of engine-

driven fuel pump.

Check pump outlet during starting.

Replace fuel pump. See Section IV.

Fuel vents plugged.

Check ram air inlet for blockage.

Pressure check each vent line. Clean or

replace vent line.

No fuel flow

when auxiliary

pump is turned

on.

Defective electric

auxiliary fuel pump

switch.

Check continuity of switch. Replace

defective switch.

Open or defective

circuit breaker.

Check visually. If not open, check

continuity. Reset. Replace if defective.

Loose connections or

open circuit.

Check connections and wiring. Tighten

connections; repair or replace wiring.

Defective auxiliary fuel

pump.

Disconnect outlet line. With proper fuel

supply to pump, fuel under pressure

should flow from outlet. Replace

defective pump.

Defective engine-driven

fuel pump by-pass

valve.

Check pump outlet during starting. See

Section IV and replace fuel pump if by-

pass valve is defective or installed

backwards.

Fuel flow

indicator

inoperative.

(Optional Equip)

No voltage to indicator.

Check voltage and ground wire. If

voltage is present and ground is good,

replace indicator, maintaining the same K

factor.

Fuel flow

Indicator comes

on but will not

show fuel flow.

(Optional Equip)

Bad wires to transducer

or defective transducer.

To check transducer, remove four screws

holding wire housing to flow vane

housing. With battery power on, pass

screwdriver back and forth over wire

housing pickups. You should get a

reading on indicator. If no reading,

replace units.