THRUSH AIRCRAFT, INC – MODEL S2R-R1340

AIRCRAFT MAINTENANCE MANUAL

7-6

Effective: 01/01/08

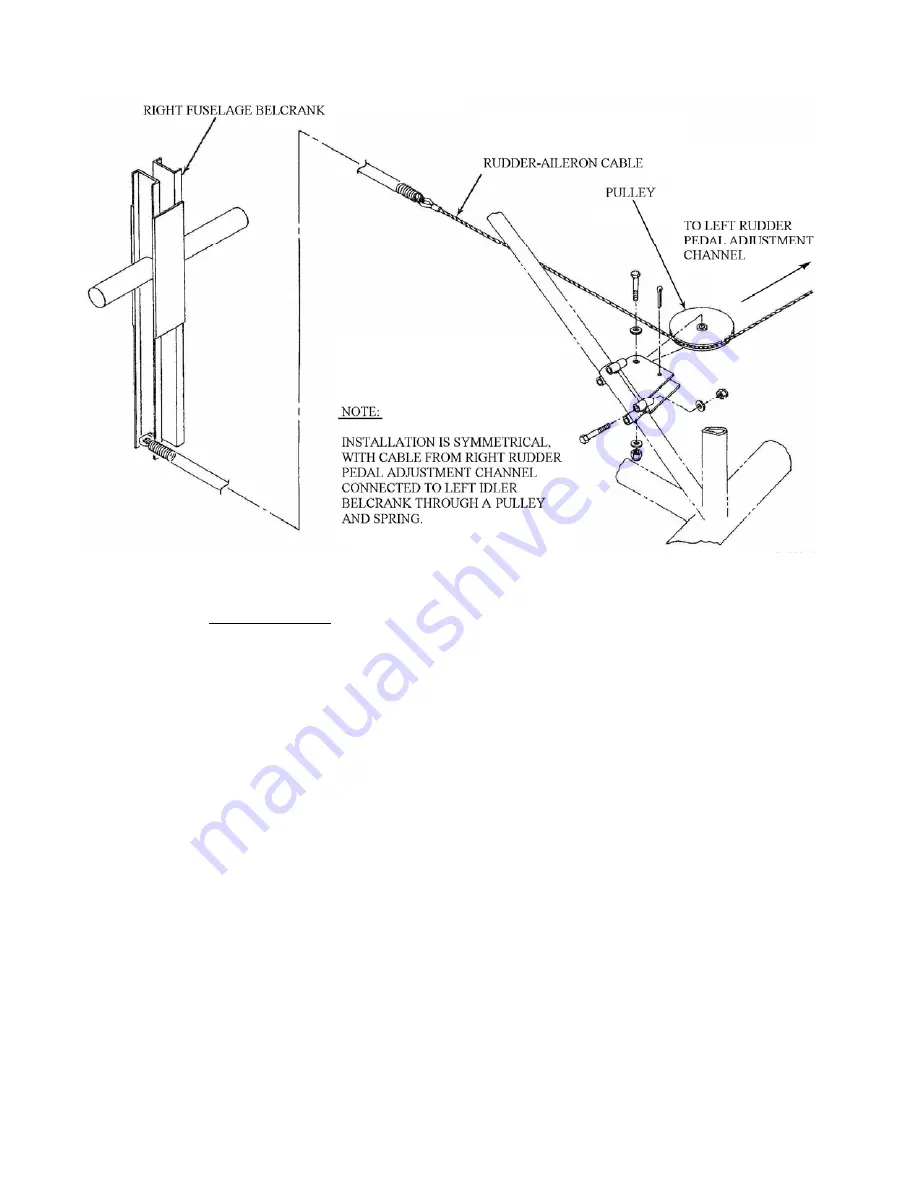

Figure 7-2: Aileron-Rudder Interconnection

Aileron Rigging

A. Assure

the

ailerons are attached and

the system push tubes are

assembled, except for the two lateral

push rods in the fuselage. Ensure

that flaps have been rigged. Rig the

ailerons as follows:

B. Clamp the ailerons at the trailing

edge of the wing tip in the neutral

position. Ailerons are in neutral

when ailerons are 1/8" below flap

trailing edge.

C. Adjust the length of the push rod

from aileron outboard wing bell crank

until inboard wing bell crank is

perpendicular to the rear spar, both

sides. This can be checked through

the inspection holes just forward of

the rear spar.

D. Attach the lower, lateral fuselage

push rod between the left fuselage

idler bell crank and the right fuselage

bell crank, adjusting the length of the

rod to fit those items.

E. Install the upper, lateral fuselage

push rod from right fuselage bell

crank to control stick torque-tube

fitting. Adjust the length of this push

rod to center the control stick.

F. Clamp control stick in center position

and free clamps on aileron. Set

trailing edges of ailerons 0.125-inch

below trailing edge of flap trailing

edge by lengthening push rod from

aileron to outboard wing bell crank.

G. Adjust and lock the aileron stops,

accessible through the inspection

holes forward of the aileron, for the

required travel. Aileron up travel

should be 21 (±1) degrees and down

travel should be 17 (±1) degrees.

H. Go back through system and lock all

check nuts.

I. To adjust the springs in the rudder-

aileron interconnect system, clamp

the rudder and ailerons in the neutral

position and adjust the turnbuckles

until the springs are the same length.