THRUSH AIRCRAFT, INC – MODEL S2R-R1340

AIRCRAFT MAINTENANCE MANUAL

8-6

Effective: 01/01/08

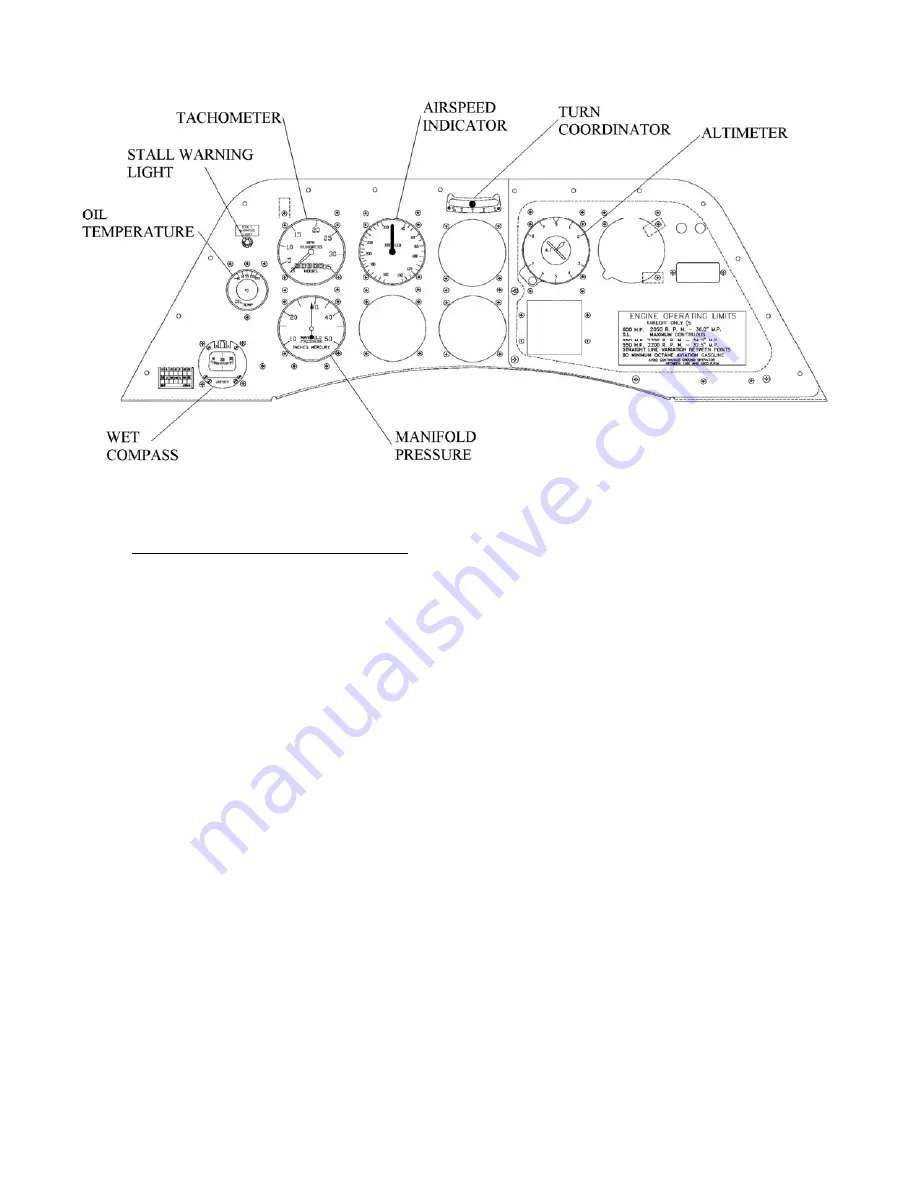

Figure 8-2: Center Instrument Panel

Magnetic Compass Compensation

Locate the aircraft in area suitable for

the method of magnetic compass

compensation to be used. Close doors

and place flaps in a retracted position.

Set the throttle at cruise position with

engine operating. Place all electrical

switches, alternator, radio and other

equipment in a mode normally used in

flight and proceed with the following:

A.

Set adjustment screws of

compensating magnets to zero.

Zero position is when the dot on the

screw is lined up with the dot on the

compass frame.

B. Position aircraft in a magnetically

north direction. Use an approved

Compass Rose if at all possible.

Adjust north-south adjustment screw

until compass reads exactly north.

C. Position aircraft in a magnetically

east direction. Adjust east-west

adjustment screw until compass

reads exactly east.

D. Position aircraft in a magnetically

south direction. Notice the resulting

south error. Adjust north-south

adjustment screw so that one-half of

the error has been removed.

E. Position aircraft in a magnetically

west direction. Notice the resulting

west error. Adjust east-west

adjustment screw so that one-half of

the error has been removed.

F. Recheck the magnetically north and

east directions to confirm that the

error is the same as for south and

west.

G. Position aircraft in successive

magnetically 30-degree directions

and record all errors on the deviation

card furnished with the compass.

TURN COORDINATOR

The turn coordinator, installed in the

center of the upper instrument panel, is

a curved, fluid-filled tube containing a

ball. The gravitational and centrifugal

forces position the ball within the tube to

indicate a coordinated turn. A correctly

coordinated turn is indicated by a

centered ball, no matter what the bank

angle. An off center ball indicates that

additional rudder is needed on the side

the ball is off to.