THRUSH AIRCRAFT, INC – MODEL S2R-R1340

AIRCRAFT MAINTENANCE MANUAL

Effective: 01/01/08

2-21

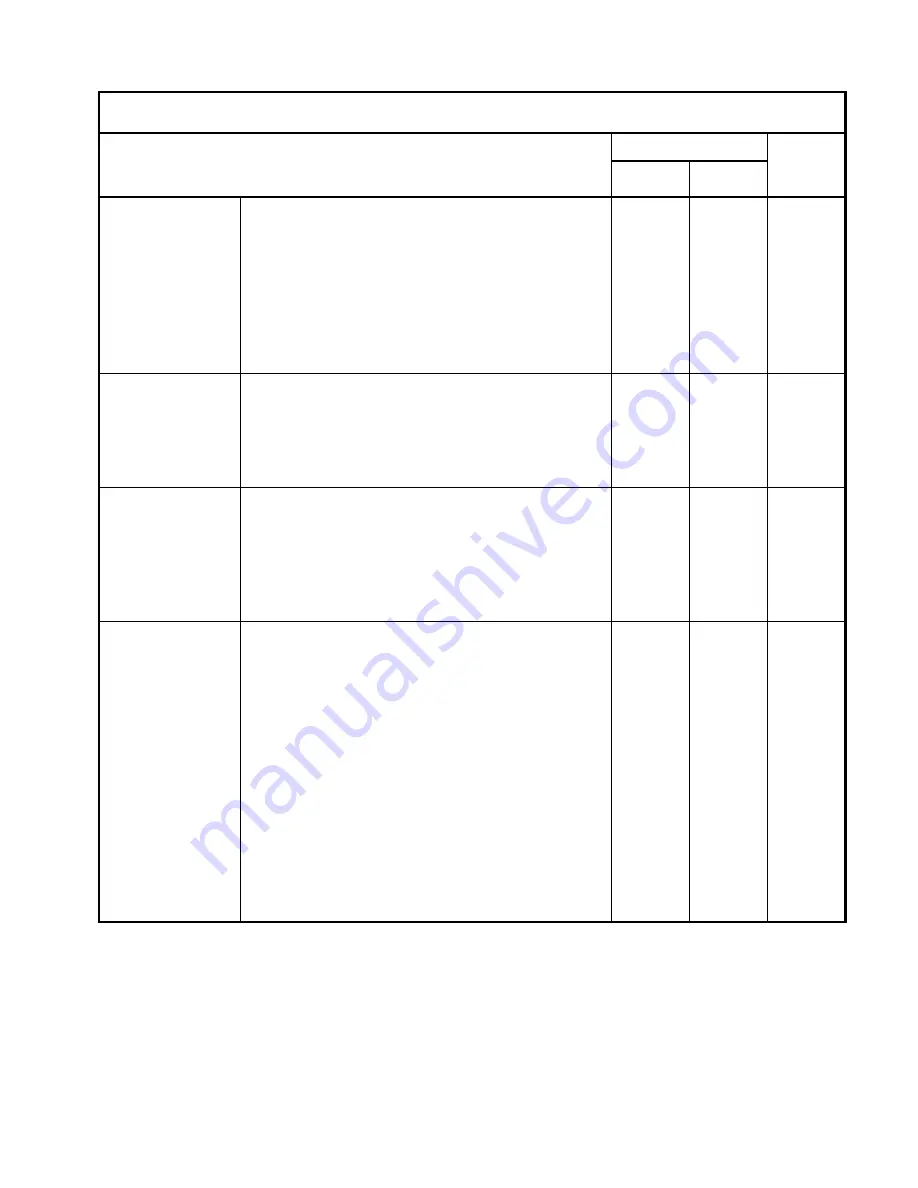

Table 2-1: ENGINE PRESERVATION PROCEDURES

(Continued)

Engine Installed:

OPERATION PROCEDURE

10 to 30

Days

Over 30

Days

Engine

not

Installed:

Carburetor

opening in the

rear case

When the carburetor is removed from the

engine, secure two ½ pound bags of

dehydrating agent to the inside of the

carburetor mounting flange cover. Secure

the cover to the flange, using acid-free

waxed paper as a gasket between the cover

and the flange. Seal the parting line of the

cover and flange with tape.

X X X

External

Inspection

Inspect the engine carefully, checking all

nuts and bolts for tightness. Inspect for

loose or broken safety wire, missing plugs,

or damaged parts. Make certain that the

intake pipes are tight at both ends.

X X

Warning Tag

Place a warning tag on the propeller shaft

and a similar tag in the airplane cockpit,

stating that the propeller or the propeller

shaft must not be turned until all the

dehydrating materials have been removed

from the engine.

X X X

Inspection

All dehydrator plugs must be inspected

every seven days and the color of the

dehydrating agent compared with that on

the humidity indicator. Any plugs, indicating

a relative humidity of more than 20 percent

are unsafe and should be replaced. When it

becomes necessary to replace a dehydrator

plug, the dehydrating agent in the exhaust

pipes and in the carburetor mounting flange

cover should also be replaced. If frequent

replacement of a particular plug becomes

necessary, the section of the engine in

which that plug is located should be

checked for inadequate sealing.

X X X