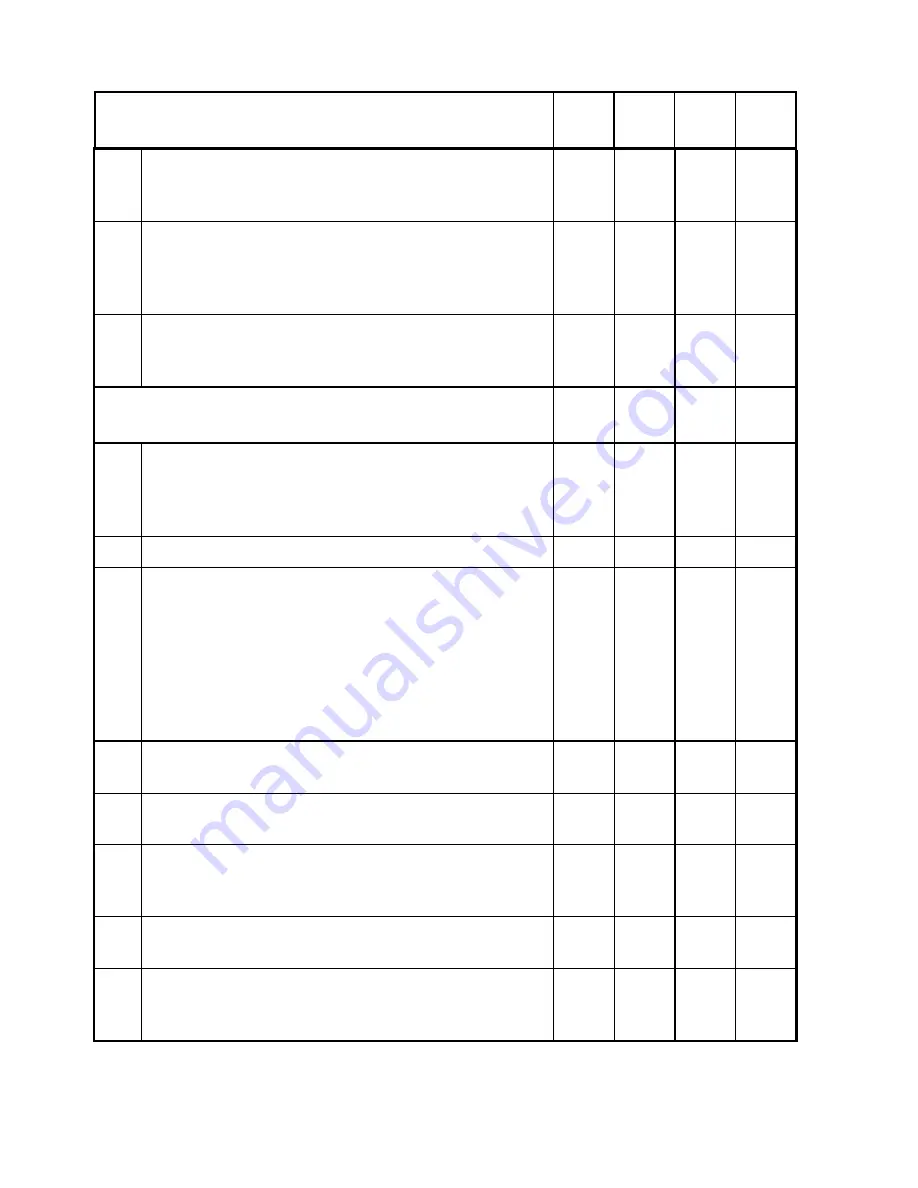

THRUSH AIRCRAFT, INC – MODEL S2R-R1340 THRUSH 600

AIRCRAFT MAINTENANCE MANUAL

2-26

Effective 01/01/08

E: AIR INDUCTION SYSTEM

(Continued)

Da

ily

50

hrs

100

hrs

400

hrs

3.

Inspect the air filter cartridges for dirt & dust

accumulation. If cartridges are significantly

clogged, replace the cartridges.

X X

4.

Check the carburetor inlet box for cracks. Check

the operation of the carburetor heat flapper for

free and complete motion, and carburetor heat

control for function and security.

X

5.

Check the carburetor heat muff around the

exhaust manifold for cracks, distortion and

clearance from exhaust pipes.

X X

F: AIRFRAME FUEL SYSTEM

Da

ily

50

hrs

100

hrs

400

hrs

1.

Draw fuel samples from wing tanks, header tank

and firewall fuel filter bowl. Check for any debris,

sediment, or water and take corrective action if

any is found.

X X

2.

Inspect, clean and reinstall firewall fuel filter.

X

* NOTE *

On new aircraft, check the firewall fuel

filter after each flight until there is no

evidence of contamination. Check the

filter after the first flight or ground run

when any upstream component is

replaced.

3.

Check the fuel boost pump for security and

upstream fuel leakage.

X

4.

Turn the fuel boost pump on and to check

operation and the downstream fuel lines for leaks.

X

5.

Check boost pump seals by observing overboard

drain while pump is running and has the fuel

system pressurized.

X

6.

Check operation of primer pump momentarily and

look for leaks.

X

7.

Inspect the fuel lines and supports for

deterioration, twists, kinks and security and for

signs of chafing.

X