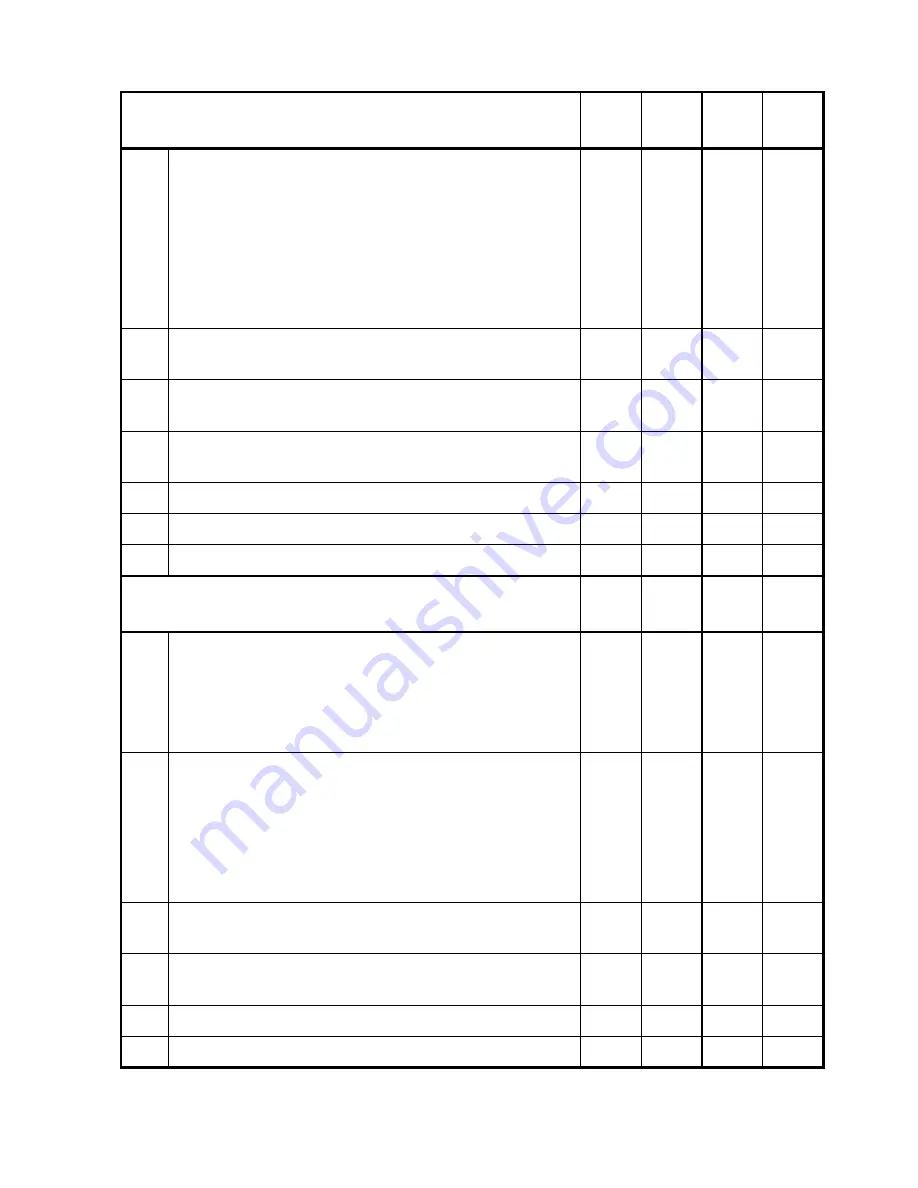

THRUSH AIRCRAFT, INC – MODEL S2R-R1340 THRUSH 600

AIRCRAFT MAINTENANCE MANUAL

Effective: 01/01/08

2-33

R: EMPENNAGE

Da

ily

50

hrs

100

hrs

400

hrs

1.

Check the travel of the movable surfaces.

Elevator up....................... 27 degrees ±1 degree

Elevator down .................. 17 degrees ±1 degree

Rudder ............................. 24 degrees ±1 degree

Tab up................................ 8 degrees ±1degree

Tab down ......................... 22 degrees ±1 degree

X

2.

Check for warped contours of the fixed surfaces

due to improperly tightened brace struts.

X

X

3.

Inspect horizontal stabilizer “V” struts, fittings, and

hardware for security, cracks and corrosion.

X

4.

Inspect all hinges for wear. Replace sealed

bearings, if needed. Lubricate hinges.

X

5.

Check security of all screws and bolts.

X

6.

Check the external skins for general condition.

X

7. Check

the

drain holes for obstruction.

X

S: AILERONS AND FLAPS

Da

ily

50

hrs

100

hrs

400

hrs

1.

Check the control movements.

Aileron up......................... 21 degrees ±1 degree

Aileron down .................... 17 degrees ±1 degree

Flap down ........................ 15 degrees ±1 degree

X

2.

Aileron servo tabs

a.

Check security of hinges

b.

Check for looseness of rod ends and bolts.

c.

Check for freedom of travel.

d. Lubricate

hinges.

X

3.

Check the security of the counterweights, which

are installed in the leading edges of the ailerons.

X

4.

Inspect all hinges for wear. Replace sealed

bearings, if needed. Lubricate hinges

X

5.

Check security of all screws and bolts.

X

6.

Check the external skins for general condition.

X