THRUSH AIRCRAFT, INC – MODEL S2R-R1340

AIRCRAFT MAINTENANCE MANUAL

4-10

Effective: 01/01/2008

passages drilled in the case. Oil, from

the tappets, feeds through the push rods

to the rockers, rocker bearings, and valve

clearance adjusting screws.

The surplus oil in the engine proper

drains into the sump, from where it is

pumped back through the scavenge

pump. Oil from the rocker boxes drains

through the push rod covers to the front

case, or through a system of intercylinder

drains to an additional compartment in

the sump where it is returned to the oil

tank. The rear case oil drains through a

tube into the supercharger case, then

into the sump.

PRESSURE RELIEF VALVE

The pressure relief valve provides a

means of adjusting engine oil pressure

so that it will remain within specified

limits during all normal engine operation.

Oil pressure on one side of the valve is

balanced against spring tension on the

other side of the valve. To adjust the

pressure relief valve, proceed as follows:

A. Remove the cap from the main oil

pressure relief valve. Loosen the

adjusting screw locknut.

B. Turn the adjusting screw clockwise

to increase, or counterclockwise to

decrease the oil pressure. Normal

oil pressure is 80 to 100 PSI.

C. After the desired adjustment has

been obtained, tighten the locknut,

reinstall the relief valve cap, and

lockwire.

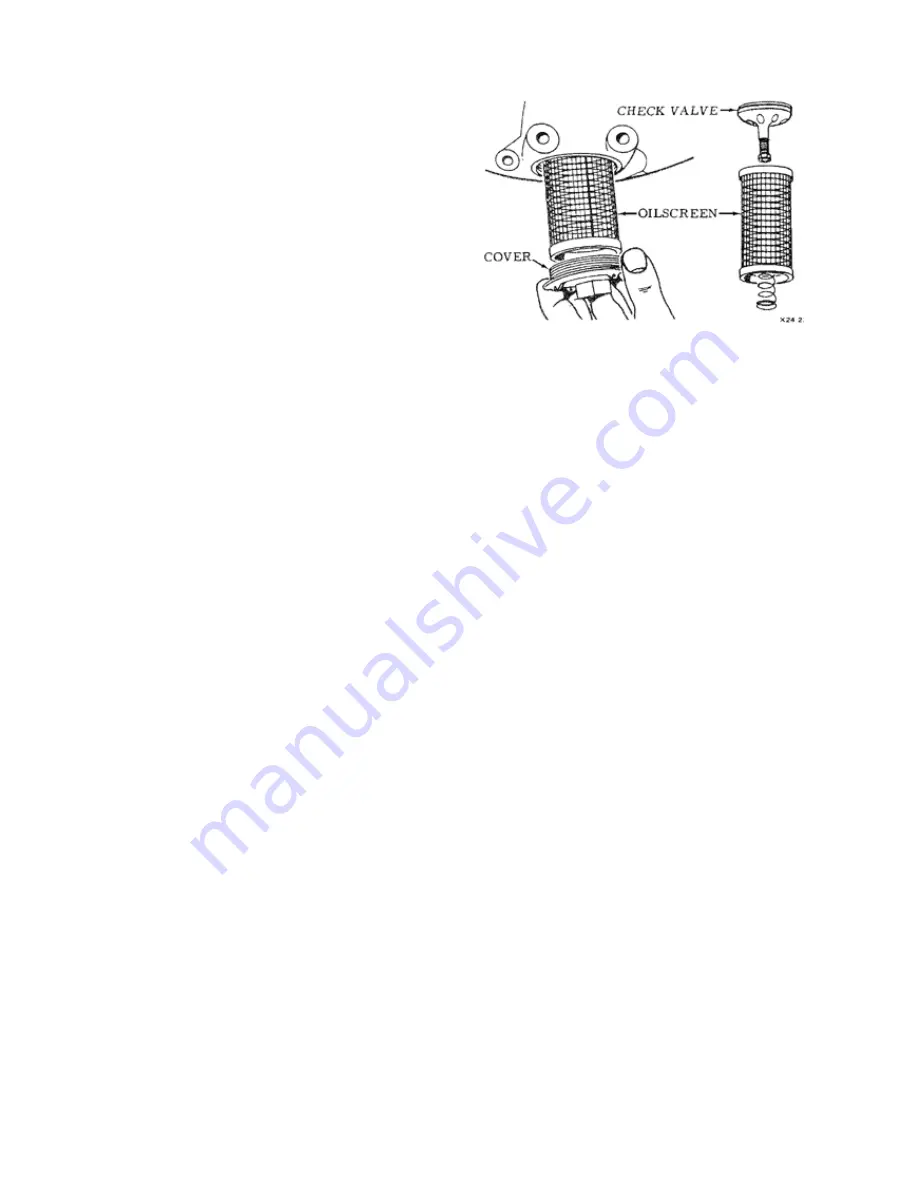

PRESSURE OIL STRAINER

The pressure oil strainer (see Figure 4-3)

is located at the bottom of the rear case.

To remove the strainer, proceed as

follows:

A. Break lockwire and loosen cover nut.

B. Remove cover, spring, oil screen

and check valve assembly.

Figure 4-3: Oil Pressure Screen

Assembly

INSTALLING OIL STRAINER

To install the oil pressure strainer,

proceed as follows:

C. Inspect the screen for distortion or

cracks; check the fit of the screen in

its chamber. Inspect the check valve

to see that it is free and seats

properly.

D. Insert the check valve assembly, oil

seal and oil screen into the chamber.

E. Install the gasket and cover.

Lockwire cover.

PRE-OILING

Pre-oiling is required prior to the initial

start of a new, newly overhauled, or

installed engine depreserved from

storage, to insure proper lubrication for

all bearing surfaces and other moving

parts. To accomplish pre-oiling, proceed

as follows:

A. Install a 50-mesh screen in the pre-

oiling system. Connect the pre-oiling

pump to the oil pressure gage take-

off on the upper left side of the rear

case. Remove the main sump drain

plug.

B. Pump oil into the engine at 45 to 65

PSI at a temperature of 60º to 70ºC

(140º to 160ºF) until approximately

one gallon of oil flows from the main

sump drain plug hole.