THRUSH AIRCRAFT, INC – MODEL S2R-R1340

AIRCRAFT MAINTENANCE MANUAL

Effective: 01/01/08

9-3

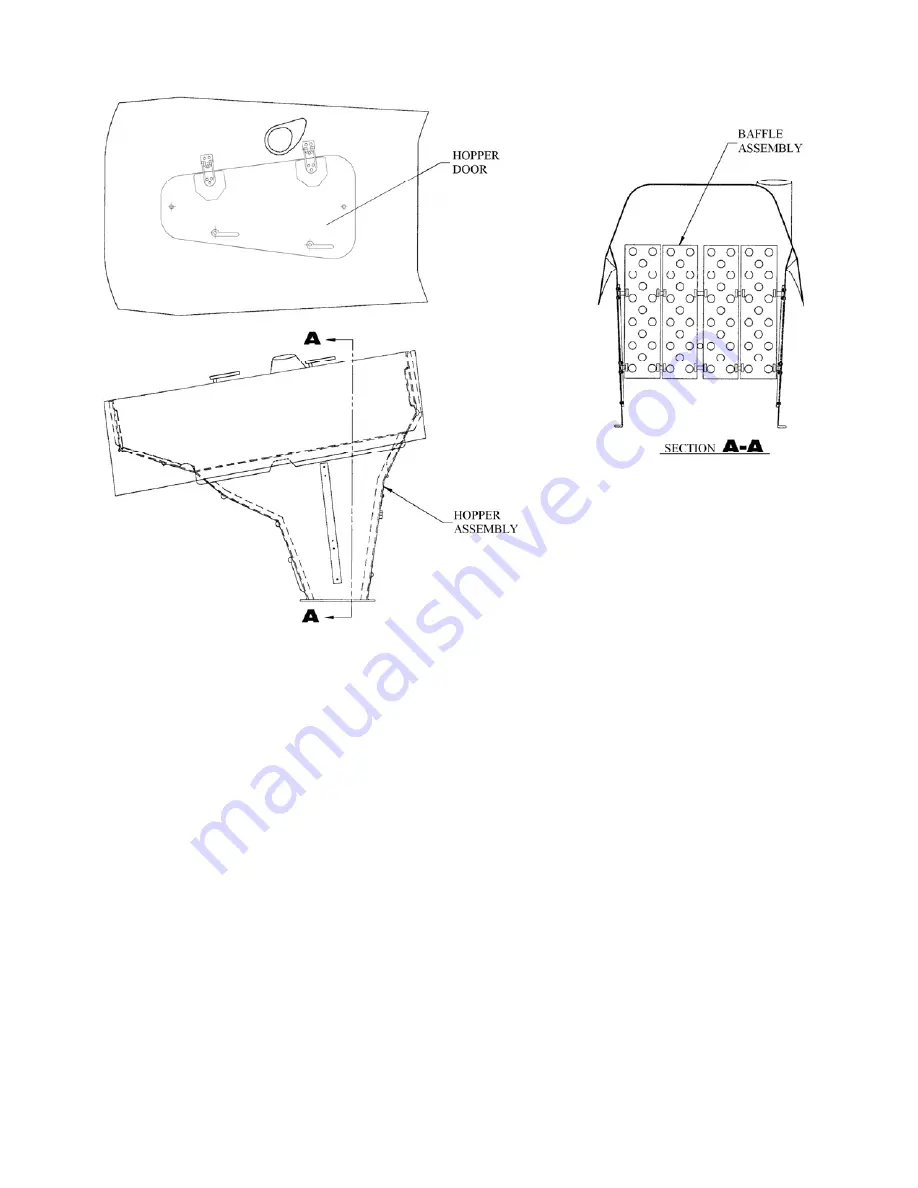

Figure 9-1: 400 Gallon Hopper

HOPPER REPAIR

Ref. Figure 9-2

Hopper repairs should be accomplished

as follows:

A. Fiberglass surfaces must be clean,

dry and free of oil, wax or other

foreign matter. If chemical erosion is

evident, sand rough areas and wash

with any good domestic detergent.

Rinse with clean water. Sand all

surfaces that are to receive a

polyester coating. Use Ashland

Specialty Chemical Company’s 7241

T15 AROPOL™ polyester resin or

equivalent for the hopper repair.

B. If damage consists only of surface

cracks, excessive abrasion or

chemical erosion, sand all affected

surfaces smooth. Extend the

prepared surface six inches beyond

the damaged area.

C. If damage consists of cracks or holes

extending completely through the

wall, sand the surfaces on both sides

deep enough to expose the first layer

of cloth.

D. Surface damage requires repairs

only to the eroded or cracked side.

Damage extending through the wall

requires repairs to both the inner and

outer surfaces of the hopper. The

number of layers in either case

should equal the original basic wall

thickness. (Figure 9-1) Highly

stressed areas, such as attach

points, require an extra layer of cloth

and mat on each side, in addition to

the basic wall thickness.

E.

Curing temperature is 70

°

F

minimum. Higher temperatures