10

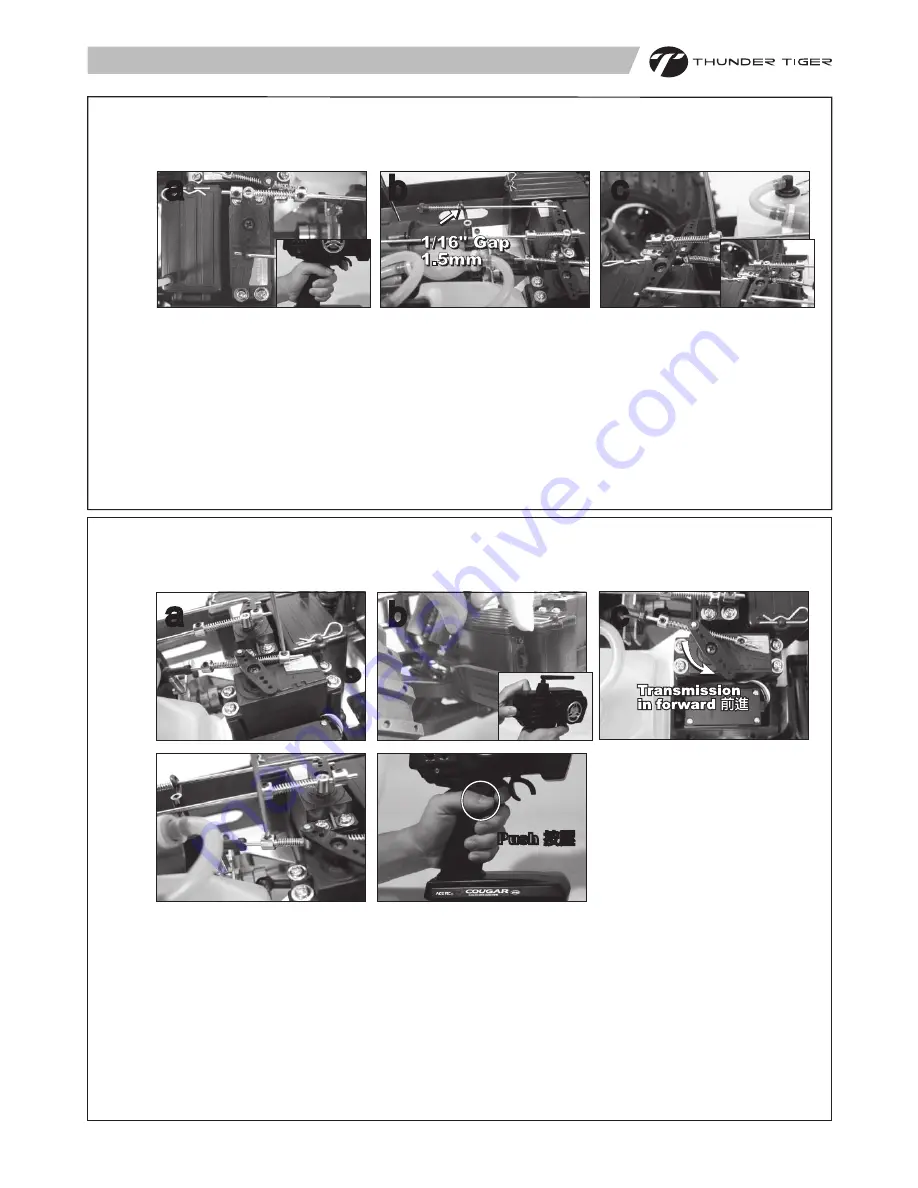

ADJUSTING THROTTLE / BRAKE LINKAGE

油門及煞車連桿調整

ADJUSTING FORWARD / REVERSE LINKAGE

倒退行走連桿調整

a.

To set the throttle/brake linkage, first the radio should be on and neutral; thus, the servo is at neutral position.

b.

With the servo at neutral, turn and adjust plastic brake adjustment nut at the end of the linkage until there is a 1/16"(1.5mm) gap

between the spring and the brake lever when the spring is not compressed. ( The brake lever should almost engages the brake

system, but not yet.)

c.

With the servo at neutral, using a 1.5mm Allen wrench driver to loosen the throttle collars. Then, manually close the carburetor,

and set the forward collar (next to the spring) with the spring slightly compressed. Then, set the other collar (rearward) next to the

linkage pivot.

a.

設定油門與煞車連桿,第一步驟應確認發射機與接收機電源開啟,伺服機與所有撥桿應位於中立點。

b.

保持油門伺服機位於中立點狀態,調整煞車連桿至彈簧與煞車撥桿保持1.5mm間隙(彈簧處於不受壓縮狀態),並且煞車幾乎咬合的

狀態加以固定。

c.

保持油門伺服機位於中立點狀態,轉鬆油門拉桿固定螺絲,手動關閉化油器,固定拉桿上之螺絲(保持彈簧為輕度壓縮狀態),再

固定另一側螺絲。

a.

Loosen the setscrews of the collars on the wire linkages using a 1.5mm Allen driver.

b.

Turn on the radio and the truck, but do not start the engine.

c.

The servo will move automatically to the position for forward driving.

d.

Move the rearward collar toward the linkage pivot collar on the servo horn until the spring is fully compressed. Uncompress the

spring about 3/16"(4.5mm) by sliding the collar back and then tighten the setscrew.

e.

Press the FWD/REV button on the radio.

f.

Repeat step 9d with the forward collar.

a.

鬆脫連桿上之螺絲(

1.5mm

)。

b.

將發射機與接收機電源打開(注意:引擎保持未發動狀態)。

c.

伺服機將自動朝車輛前進方向位置擺動。

d.

移動連桿上後側之調整螺絲(如圖示),將彈簧完全壓縮之後再退出約

4.5mm

的距離,將螺絲固定。

e.

壓下遙控器上倒退切換鈕(如圖示)。

f.

參照步驟

d

,調整連桿上前端之調整螺絲。

a

b

c

a

b

c

a

b

c

a

b

d

e

c

10

11

Push

按壓

Push

按壓