STORING YOUR CAR

保養建議

18

To keep your truck in good working condition, there are a few steps that need to be followed:

a.

Remove the fuel from the tank. Both your truck and squeeze bottle should always be stored free of fuel.

• Empty any fuel remaining in your squeeze bottle back into the fuel container.

• Draw the fuel in the fuel tank into the squeeze bottle and squeeze it back into the fuel container.

• Repeat the above step as necessary until the tank is as empty as is possible.

• Make sure to store your fuel container out of the reach of children in a cool, dark location and make sure that the lid is securely

tightened.

b.

Put the glow plug igniter on the glow plug, hold the carburetor all the way open and bump the engine by using a starter a few times. This

will make sure that there is no unused fuel in the engine or fuel lines.

c.

Use after run oil.

• Start out by taking an old toothbrush and cleaning off the dirt around the base of the filter. This will help to keep grit out of your

engine.

•

Remove the filter from the carburetor.

• Place 2-6 drops (as recommended by after run oil manufacturer) directly into the carburetor.

• Slowly bump the engine to distribute the oil evenly throughout the engine.

• Reinstall the air cleaner.

d.

Clean your truck -storing it dirty can lead to a gummy build up and poor performance.

• Use nitro car cleaner, WD-40 or equivalent to clean up the dirt and oil.

• Use an old toothbrush or a small paintbrush to get to the hard to reach areas.

• A damp cloth works well for cleaning the body. Stubborn dirt and oil on the body is best removed with any diluted organic

solvents (Simple Green, etc).

e.

Lubricate the wheel bearings, drive axle joints, clutch bell bearings and suspension pivots using thin oil.

f. IMPPORTANT! Verify that BOTH the radio and receiver switches are turned off. It is very disappointing to have dead batteries

next time you want to run your truck.

為確保您的愛車狀態處於良好情況,請依照下列步驟保養您的愛車

a.

將油管、注油器與油箱內之燃油完全洩除。

•

利用注油器將油箱內燃油洩下,儲存於油桶內。

•

再將注油器內殘油洩下,儲存於油桶內。

•

重複上述步驟將燃油清理乾淨為止。

•

遙控模型專用燃料,具相當高的揮發性與低燃點特性,請您於使用或儲存時遵照使用燃油之相關規定;使用時必須遠離火源,儲藏時必須

避免日曬並放置於乾燥陰涼處,以及兒童無法取得處。

b.

將電夾夾住火星塞,啟動引擎數次,可協助清理引擎室內之殘油。

c.

使用引擎專用保養油保護引擎。

•

建議使用牙刷將引擎外圍與空氣濾清器上灰塵清理乾淨。

•

將空氣濾清器拆下

•

滴

2

至

6

滴專用保養油至化油器內。

•

使用啟動器轉動引擎,將保養油塗佈均勻。

•

將空氣濾清器裝回。

d.

清理您的愛車。

•

使用引擎模型車專用清潔劑、

WD-40

或是其他清潔劑,將車身上之油漬、

塵土

..

等清理乾。

•

建議使用牙刷將死角清理乾淨

•

將車殼使用清潔劑清理乾。

e.

建議將輪胎軸承、傳動結構、驅動齒輪..等上油保養。

f.

重要!收藏您的愛車前記得將發射機與接收機電源關閉。

14

SET UP

設定

19

a.

Your truck's two-speed shift point is preset from the factory. It should shift into 2nd gear within

12-15 feet

on a full-throttle, standing-start

acceleration.

b.

If you wish to adjust the shift point,

first shut down the engine

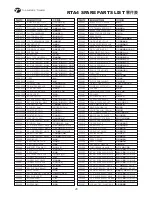

then open the two-speed access cover on the transmission case. Align

the

BLACK adjustment set screw

with the opening on the 2nd gear as shown on the diagram.

c.

Using a

2mm Allen wrench

, turn the black adjustment set screw

clockwise to make the two-speed shift later

; turn it

counterclockwise to make the two-speed shift earlier

. Only use

1/8 turn increments

whenever you adjust your two-speed.

d.

Close the two-speed access cover on the transmission case.

e.

If it is screwed in or out too much, reset the black set screw as following. First, screw in the

black set screw

clockwise gently until it is

fully compressed. And then turn the black set screw counter-clockwise about 3 turns. Re-attach the main gear shell protector.

f.

Be careful not to touch any hot engine components in the area.

a.

您的愛車原廠即已設定最佳變速點,從完全靜止狀況下,全油門速度下大約行走

5

公尺至

8

公尺之間即會跳上第二段速度。

b.

若您欲設定新的變速點,請先關閉引擎。將變速箱外殼上之覆蓋片開啟,使用六角扳手調整設定螺絲(如圖示)。

c.

使用

2mm

六角扳手調整設定螺絲,順時針旋轉將延後變速點;逆時針旋轉將提前變速點。

注意:每次調整以

1/8

圈為單位。

d.

將變速箱外殼上之覆蓋片關閉。

e.

重新安裝調整螺絲及彈簧回復原廠設定值:首先,順時鐘方向慢慢的將調整螺絲鎖入直到完全鎖緊。然後逆時鐘方向將黑色調整螺絲轉

1.5~1.75

圈。重新裝上齒輪保護罩。

f.

注意調整時不可碰觸引擎部位,避免受傷。

請注意固定螺絲與調整螺絲的分辨,以防轉錯螺絲造成變速箱故障。

Two-Speed Adjustment

兩段變速器調整

黑色調整螺絲

Shift

Earlier

Shift

Later