15

Front & Rear Toe-In / Toe-Out

前後輪束角調整

a.

Use a

1.5mm Allen wrench

as shown to adjust the front & rear toe-in.

b.

Lengthening the

Turnbuckles

will increase the amount of toe-in, shortening them

will increase the amount of toe-out.

c.

The notch on the turnbuckle indicates the side that has the

right-hand thread

. Use

it as a guide to determine which way to turn the turnbuckle when adjusting its length.

a.

使用

1.5mm

六角扳手調整前、後輪束角。

b.

增長螺距將會增加內束角角度;縮短螺距將會增加外束角角度。

請參照本說明調整您愛車前、後輪的傾角。

Front & Rear Camber

前後輪傾斜角調整

a.

Use a 2.5mm Allen wrench as shown to adjust the front & rear camber.

b.

Turning the upper pivot ball clockwise increases camber towards the negative side;

turning it counter-clockwise increases camber towards the positive side.

a.

使用

2.5mm

六角扳手調整前、後輪傾斜角(如圖示)。

b.

調整上輪軸球頭順時針旋轉將增加負傾斜角;反之,將增加正傾斜角。

請參照本說明調整您愛車前、後輪的傾角。

Ride Height

調整車身高度

a.

The truck ride height can be increased by adding preload clips to the shocks.

Removing preload clips will decrease the ride height.

b.

Compress the spring and insert the preload clips between the spring collar and the

shock body flange.

a.

車身高度可利用避震器調整墊片改變。增加調整墊片可增加車高;反之則降低車高。

b.

安裝或拆卸墊片時,請壓縮避震器彈簧再置入或取出墊片即可。

Slipper Clutch

扭力限制器調整

a.

Use a 7mm nut driver to adjust the slipper clutch.

b.

Tighten the slipper nut until the spring is fully compressed.

c.

Once you've reached the point where the spring is fully compressed, loosen the

slipper nut 1/8turn.

d.

Do not run you truck with the slipper nut any looser than 1/8turn from full spring

compression. Setting the slipper too loose may result in a damaged spur gear.

a.

使用

7mm

扳手調整扭力限制器。

b.

將螺絲上緊至彈簧完全壓縮。

Shock Springs

避震器彈簧搭配

Stiffer springs will give you better handling and higher cornering speed on

smooth surfaces such as asphalt, concrete, and hard pack dirt. Soft

springs are better for rougher terrain, rock crawling and jumping. Softer

springs will increase the rollover tendency of the truck at higher speeds.

較硬的避震器在平坦堅硬的跑道上(例如柏油路面),將可提供較好的操

控性與過彎速度。較軟的避震器適合於崎嶇不平的路面(例如碎石地)以

及跳躍動作,並且可以降低翻車的機率。

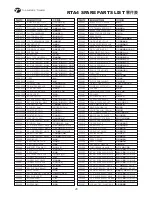

Part Number

產品編號

PD1473

PD1474

PD1475

PD1476

Spring Color

彈簧顏色

Blue(Std)

藍

Gold

金

Red

紅

Copper

紅銅

Spring Rate

彈性係數

4.40 lb./in

5.10 lb./in

5.95 lb./in

6.90 lb./in

Relative Stiffness

相對軟硬度

Softest

最軟

Stiffest

最硬

Optional Gearing

齒比搭配

Additional gearing is available for your RTA4 SC Racing Truck. Additional gearing allows you to match your engine and transmission to

your driving situation. Bigger gears on the clutch bell (or smaller slipper gears) will result in greater top speed, but will have slower

acceleration from a stop (see chart below). If you change the gearing you will need to reset the gear mesh:

1.

Loosen (or tighten if engine was removed) the four engine mounting bolts located on the underside of the truck until you can just slide

the engine forward and backward.

2.

Slide the engine up to the spur gear until the teeth on the clutch bell are meshed tightly with the teeth on the slipper gear.

3.

Move the engine back a little bit (1/32" or 0.8mm). Check the mesh by holding the smaller gear with one hand and rocking the bigger

gear back and forth with the other. The big gear should rock back and forth slightly with little effort. A gear mesh that is too tight will be

noisy, have lower performance and could ruin the gears.

Notch

刻槽向內

Add Pos.

Camber

正傾角

Add Neg.

Camber

負傾角

Loosen

Slipper

Clutch

鬆

Tighten

Slipper

Clutch

緊

c.

彈簧完全壓縮後,再將螺帽轉鬆

1/8

圈。

d.

請勿將固定螺帽鬆脫超過

1/8

圈,避免造成大主齒損壞。

RTA4 SC

引擎四驅競賽卡車齒輪比可以依照您的需求選擇搭配。較大的離合器罩齒輪(或是搭配較小的大主齒輪),將會提高您愛車的尾速。

但是加速度卻會變弱(可參考下列附表)。若您有變更齒比的需求,您可參照附表建議重新搭配。

1.

將車底板上之引擎固定螺絲鬆脫,直到您可自主移動引擎即可。

2.

將引擎向上移動,直到離合器罩齒與大主齒齒輪緊密接合。

3.

將引擎向下方移動一點間隙(約

0.8mm

),並徒手轉動兩個齒輪是否順暢轉動,來調整間隙。若是轉動時齒輪噪音過大表示,齒輪搭配過

緊,將會降低引擎性能表現。

Better Acceleration

加速性能較強

Higher Top Speed

尾速較快

Final Reduction

2nd gear

第二段齒輪終傳齒比

11.24

9.95

Final Reduction

1st Gear

第一段齒輪終傳齒比

16.26

14.38

Slipper Gear size

大主齒規格

46T(TT-Std) PD7215

46T(TT-Std) PD7215

23T (Std.) PN1805

Clutch bell gear size

離合器罩齒輪規格

26T PN1808