25

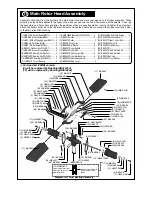

Flying Adjustments (1)

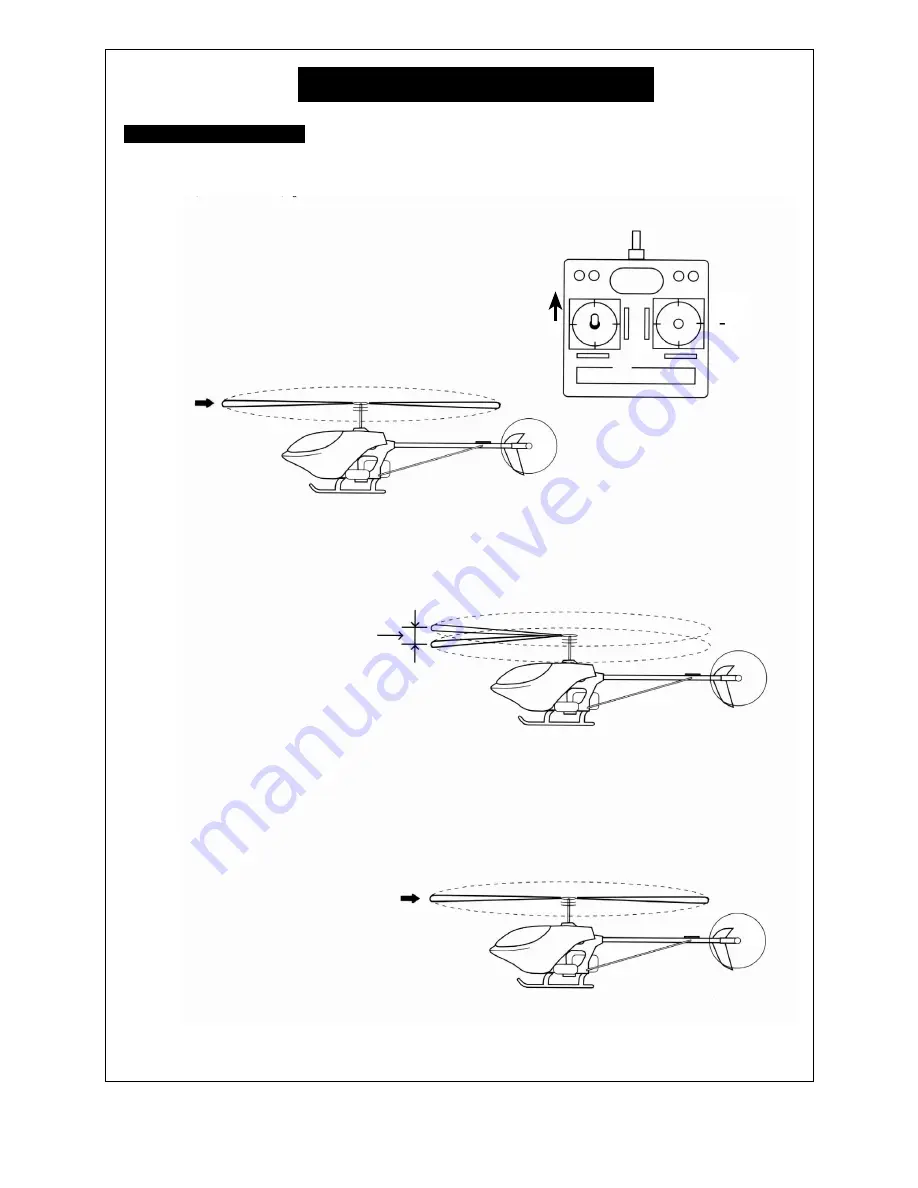

Tracking adjustment ...

When the two main rotor blades are in track it means their blade tips

follow the same path as they rotate.

(1) Rev up the motor until the helicopter becomes

light on its skids. Stand about 15 feet(4 meters)

alway from the helicopter.

(2) When the two main rotor blades are in

track it means the blade tips should follow

the same path as they rotate.

(3) When both blades are in track, the blade

tips will appear to overlap as seen from

the edge of the rotor plane.

If the blades are out of track, then adjust

one of the pushrods that connects to the

main rotor blade pitch arm.

Redo steps (1) to (3) until

the blades are

tracking

properly.

In hover, the main blades should be

around 5.5 to 6 degrees in pitch.

out of track

in track

increase

throttle gently

and not too

much

Summary of Contents for RAPTOR 30

Page 1: ......

Page 24: ...22 FLIGHT TRAINING SECTION...

Page 32: ...30 MAINTENANCE SECTION...

Page 38: ...36 PARTS LIST SECTION...