Safety Precautions

安全注意事項

Index

索引

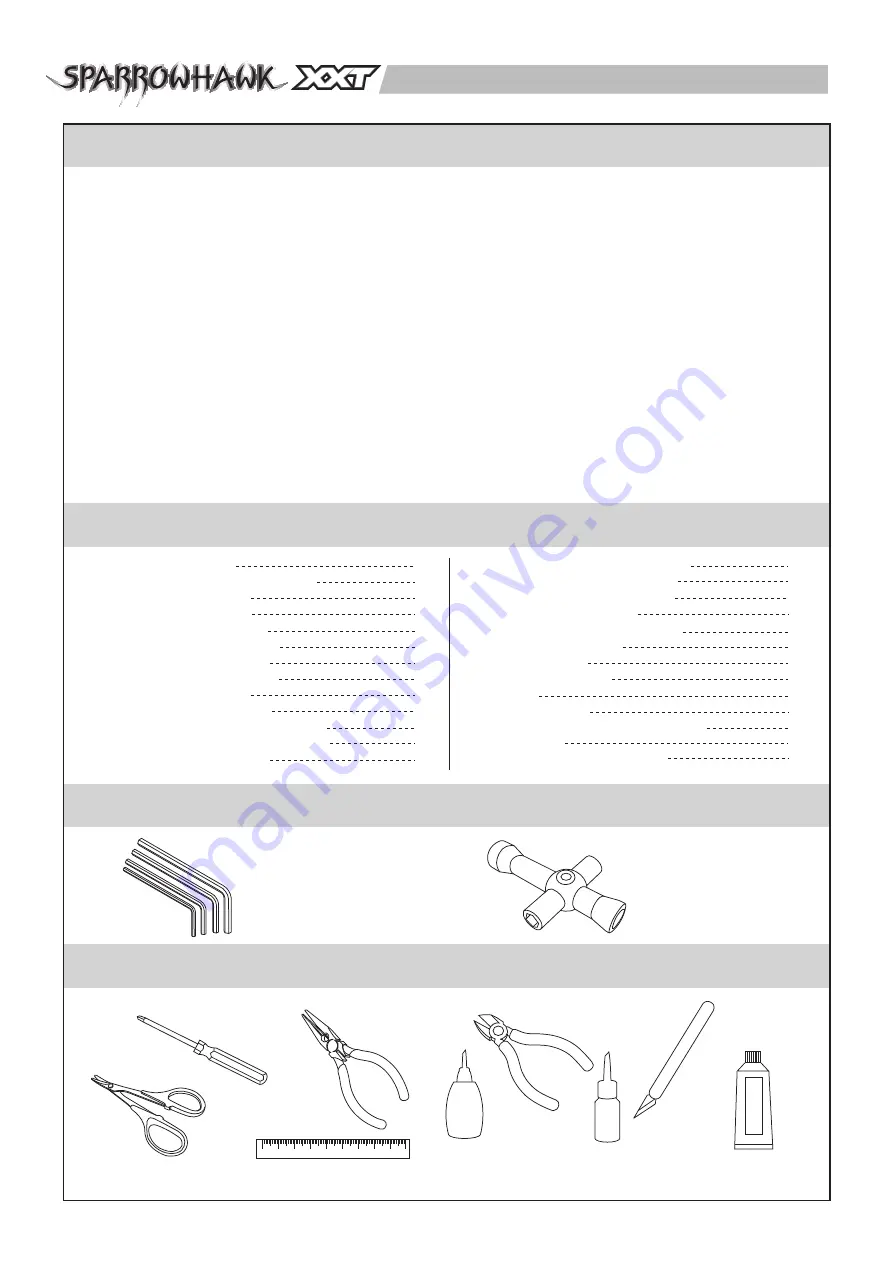

Tools Included

內附工具

Tools Required For Assembly

組裝維修工具

C A

P.2

P.2

P.3

P.3

P.4

P.4

P.6

P.7

P.10

P.12

P.13

P.13

P.14

P.14

P.15

P.15

P.16

P.17

P.17

P.18

P.19

P.23

P.29

P.31

P.32

P.33

1

Hex Wrenches

1.5 / 2.0 / 2.5 / 3.0mm

六角板手組

4-Way Cross Wrench

十字套筒

Philips Screwdrivers

(L/M/S)

十字起子

Needle Nose Pliers

尖嘴鉗

Hobby Knife

模型用切割刀

Wire Cutter

斜口剪

Lexan Body Curved Scissor

車殼專用剪

Ruler

尺

Super Glue

(CA Glue)

快乾膠

Grease

潤滑油膏(黃油)

Thread Locking Adhesive

(Threadlocker)

螺絲防鬆膠

Please read all of the instructions and familiarize yourself with the product and its controls before operation.

1. This product is not a toy. It is a high performance model car therefore it is important to familiarize yourself with the model,

its manual, and its construction before assembly or operation. Adult supervision is necessary for children operating this

model.

2. Always keep this instruction manual on hand during assembly and for operating reference.

3. Do not use a power screwdriver to install screws into plastic parts. A power screwdriver’s high rotation speed can heat

up the screw being installed which can result in some melting of the plastic parts or stripped threads.

4. For best performance, it is important to make sure all the moving parts can move freely without binding.

5. This product, its parts, and its assembly tools can be harmful to your health. Always exercise extreme caution when

assembling and operating this product. Keep away from any high speed rotating parts during operation.

感謝您購買雷虎科技產品,在您開始操作本產品前,請詳閱本產品說明書。

1.

本產品為高性能模型產品非一般玩具,組裝與操作過程皆須由成人陪同。請詳讀此本使用說明書,避免因組裝錯誤與操作不當造成損壞。

2.

請妥善保管此說明書,對於後續維修、操控說明將可提供您協助。

3.

請勿使用電動工具旋緊自攻螺絲於塑膠零件上,可能導致塑膠零件融化或滑牙。

4.

請檢視所有活動部位零件是否不受干涉,可靈活作動,以達到車輛最佳性能。

5.

此項產品具有相當之危險性,於組裝、調整、操控上的不熟悉都可能造成自身或他人的傷害,當發生這些傷害事件時製造商是可以免除責

任的,建議您於初次使用本產品前,先行請教具有相當程度經驗同好或是專業雷虎經銷商與模型專賣店。

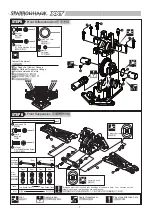

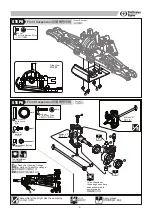

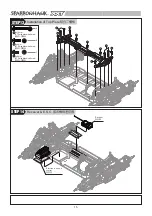

STEP12 Installation of Motor Mount

結合馬達組

STEP13 Installation of Top Plate

結合二樓板

STEP14 Receiver & E.S.C.

接收機與速控器

STEP15 Steering Servo

轉向伺服機

STEP16 Installation of Battery Pack

安裝電池

STEP17 Tire/Wheels

輪胎及輪轂

STEP18 Body Shell

車殼

EXPLODED VIEW

爆炸圖檢索

PARTS

零件表

OPTION PARTS

改裝配件

WHEEL & TIRE OPTION PARTS LIST

輪胎與輪轂

BODY SHELLS

車殼

OPTIONAL ELECTRONICS

選配電子產品

Manual Format

說明書使用方式

Symbols Used Throughout The Manual

符號說明

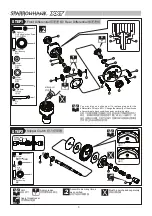

STEP1 Rear Differential

後差速組

STEP2 Slipper Clutch

扭力控制器

STEP3 Rear Differential Unit

後差速箱

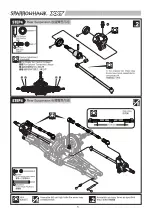

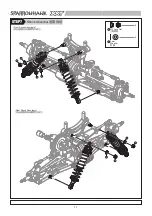

STEP4 Rear Suspension

後擺臂懸吊組

STEP5 Front Differential Unit

前差速箱

STEP6 Front Suspension

前擺臂懸吊組

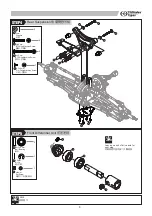

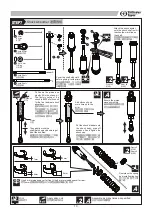

STEP7 Shock Absorber

避震器組

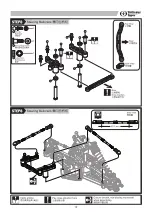

STEP8 Steering Bellcrank

轉向曲柄組

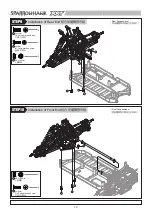

STEP9 Installation of Rear End

結合後擺臂懸吊組

STEP10 Installation of Front End

結合前擺臂懸吊組

STEP11 Motor Pinion Gear

馬達驅動齒