Low speed mixture

1

1/4

turns out

Clockwise=Leaner

Counterclockwise-

Richer

中低速混合比:

1

1/4

圈

(

鎖到底退回

)

順時針

=

貧油

逆時針

=

富油

Low speed mixture

5

1/2

turns out

Clockwise=Leaner

Counterclockwise-

Richer

中低速混合比:

5

1/2

圈

(

鎖到底退回

)

順時針

=

貧油

逆時針

=

富油

High speed mixture

2

1/2

turns out

Clockwise=Leaner

Counterclockwise-

Richer

高速混合比:

2

1/2

圈

(

鎖到底退回

)

順時針

=

貧油

逆時針

=

富油

Idle speed:

1mm

Adjust Idle

Screw

until 1mm is

obtained.

怠速:

開口調整為

1mm

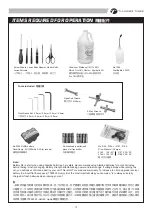

Factory Carburetor Settings.

原廠設定值

a.

To set the high speed needle (large needle sticking out from the carburetor body), turn the screw as pictured. Initial high speed needle setting

should be 3 turns (close the needle completely, then back out 2

1/2 turns). Clockwise turn will provide leaner setting (lower fuel to air mixture), and

counterclockwise turn will provide richer setting (higher fuel to air mixture).

b.

To set the carburetor idle (small needle sticking out from the carburetor body), turn the screw as pictured. Initial idle setting should leave 1mm

carburetor gap. Clockwise turn will provide higher idle (larger carburetor opening), and counterclockwise turn will provide lower idle (smaller

carburetor opening). For more details about the engine setting, please refer to ENGINE BREAKIN/ SETTING procedures to properly set the engine.

c.

To set the low speed needle (The low-speed mixture screw is located in the end of the carburetor). turn the screw as pictured. Initial low speed

needle setting should be 6 1/2 turns (close the needle completely, then back out 6.5 turns). This screw controls how much fuel enters the engine at

idle and low throttle. This adjustment will smooth the idle and improve the acceleration to mid speed. Make this adjustment with the throttle closed,

after setting the idle. Turn the screw clockwise gently until it stops. DO NOT over tighten.

d.

Remove the outer foam from filter and make it moist evenly with a few drops of fuel. Put the filter in a plastic bag and knead it until the foam is

saturated, but not soaked.

e.

Finally, make sure the air cleaner boot is securely fastened with a zip-tie. Never run your vehicle without the air filter .If the vehicle will be operated

in an area with fine dust, use filter oil or caster oil instead of fuel. It is important that the foam is only moist to trap dirt and allow air passage. With

the foam too wet, limited air can pass through; therefore, limiting engine performance.

a.

高速油針調整:調整高速油針(突出於化油器本體之較大螺絲),如圖示。於調整前應先保持油針於開啟

2.5

圈的位置(油針完全鎖緊後再鬆開

2.5

圈)。高速油針順時針旋轉,化油器將會呈現較為貧油設定;逆時針旋轉將會呈現較為富油設定。請參考引擎使用手冊來設定您愛車的引擎。

b.

怠速設定:設定引擎怠速轉速用螺絲,突出於化油器本體之較小螺絲(如圖示),於調整前注意化油器應保持

1mm

的開口。怠速螺絲順時針旋轉,怠

速轉速提高;逆時針旋轉,怠速轉速降低。請參考引擎磨合建議來設定您愛車的引擎。

c.

低速油針調整:調整低速油針時需卸下車殼(低速油針位於化油器本體末端如圖示)。調整前應先保持油針於開啟

6.5

圈的位置(油針完全鎖緊後再

鬆開

6.5

圈)。正確調整此油針可讓怠速與中低速更加順暢,調整此油針時需將油門關閉,以及怠速設定完成後。

d.

空氣濾清器:本車搭配高性能空氣濾清器,建議您於使用前於濾清器上塗抹適量濾清器專用油,可加強過濾粉塵,避免進入化油器造成引擎損壞。

e.

最後確認固定濾清器之束帶是否確實綁緊引擎請勿於未安裝空氣濾清器情況下運轉,並且注意濾清器的清潔工作以避免造成引擎的損壞與壽命簡短。

建議使用適當的濾清器專用油,強化過濾的功能。

d

d

e

a

b

c

ADJUSTING CARBURETOR

化油器調整

11

10

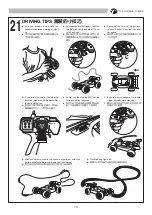

OPERATING RADIO THROTTLE/ BRAKE FUNCTION

遙控器設定-油門、中立、煞車

a.

Check the radio throttle/brake functions. With the radio transmitter and receiver on, pull the trigger / push the stick forward. The

carburetor should be fully opened and the brake disengaged. To reverse this function, flip the throttle/brake servo reverse switch.

b.

Return the trigger / stick to neutral. The carburetor should be closed to a point where the idle has been set (see step 8 for settings),

and the brake still disengaged. If not, use the throttle/brake trim lever to correct it.

c.

Push the trigger / pull the stick backward. The carburetor opening should still be the same at neutral, throttle spring compressed

slightly, and the brake engaged.

a.

確認油門、煞車功能。請先將發射機與接收機電源開關打開,以檢查油門、煞車作動是否正常作動。將油門板機(桿)向內拉上推到

底時,化油器應完全開啟,煞車脫離(可輕輕轉動輪子,確認煞車是否完全脫離),若方向不一致,請調整油門的正逆轉開關。

b.

將油門板機(桿)推回中立點時,化油器應關閉至定點,煞車仍為脫離狀態;若狀態有所偏差,請調整油門微調鈕。(油門、煞車連

桿的正確設定,請參考步驟

8

)

c.

油門板機(桿)向煞車方向推時,化油器應關閉至定點,但煞車須為鎖死狀態。

Summary of Contents for TOMAHAWK XL

Page 27: ...JD7532...