Page 2

5. RATINGS

The

STAR-BRAKE

should be used at its published

horsepower rating. The protective overload is sized for

the nominal motor current, and may not protect a motor of

lower horsepower. For overload rating, see section 7.2.1.

Any application requiring frequent or severe braking, or

operation more often than two stops per minute, may

require a different model

STAR-BRAKE.

Applications involving exceptionally high inertia, such as

press flywheels, extractors, etc., may require models with

longer than the standard 15-second maximum braking

time. For information on applications such as these,

please consult the factory or your local sales representa-

tive.

All

STAR-BRAKE

units may be used in normal ambient

temperatures. The maximum temperature at the hottest

part of the heat sink should not exceed 50 degrees C. At

temperatures below O degrees C, braking levels may

decrease.

STAR-BRAKE

units have internal fuses. These are

special, fast-acting, semiconductor fuses. They must be

replaced with the same type as originally supplied.

THE USE OF IMPROPER FUSES IN THE

STAR-8RAA'fWILL VOID THE WARRANTY!!!!

6. INSTALLATION

6.1 Mounting

The

STAR-BRAKE

may be mounted in any convenient

location, and in. any orientation, although vertical is

preferable. Keep it away from sources of vibration, dust,

dirt and extremes of temperature. Once mounted, it

normally needs no maintenance.

6.2 Wiring

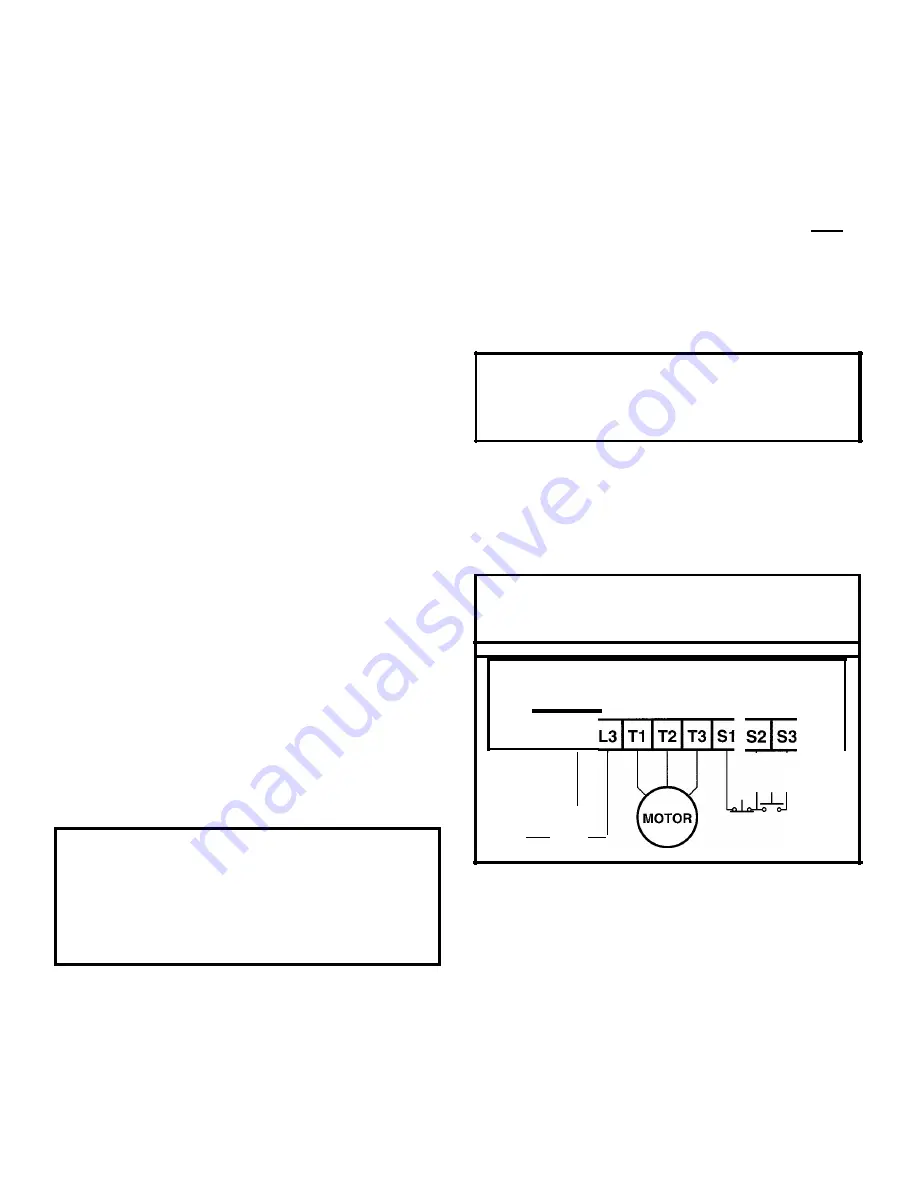

6.3 Control Wiring

1. Connect a dry, momentary, normally closed (Stop)

pushbutton between Terminals S1 and S2.

2. Connect a dry, momentary, normally open (Start)

pushbutton between Terminals S2 and S3.

Note: If a programmable controller is used to control the

Start and Stop function, relay type output modules must

be employed. See section 9.4.

6.4 Power Wiring

WARNING ON THE USE OF

POWER FACTOR CAPACITORS

6.4.1

Three Phase Motor

INPUT (LINE POWER) SIDE: Terminal L1, L2, L3

OUTPUT (MOTOR) SIDE:

Terminal T1, T2, T3

Figure

6.4.1

6.4.2

Single Phase Motor

3 Phase Wiring

All wiring to the

STAR-BRAKE

is done to terminals provided.

In general, the wires connected to terminals L1, L2, L3,

T1, T2, T3 must be able to carry the full motor starting and

running current. Wires connected to S1, S2, S3 may be

"control wire" gauge.

Input (Line Power) Side: Terminal L1, Terminal L2

Output (Motor) Side:

Terminal T1, Terminal T.2

Note that for a given voltage and horsepower rating, a

single phase machine will draw greater current than the

three-phase equivalent. Be sure not to exceed

either

the

horsepower or current rating of the

DAR-8/iAl(F.

The STAR-BRAKE will be damaged if power factor

or other capacitors are present across the motor

leads. If capacitors are used, they must be placed

on the LINE side.

Be sure to check if the MOTOR IS ROTATING IN

THE PROPER DIRECTION before operating the

machine. If it is not, interchange the wires con-

nected to Terminals T1 and T3.

,

Stop Start

L1

L2 -

L3

STAR-BRAKE

•

ALL WIRING SHOULD CONFORM

WITH NATIONAL AND LOCAL

ELECTRICAL CODES.

•

BE CERTAIN THAT POWER IS TURNED

OFF AND LOCKED OUT, BEFORE

PROCEEDING WITH ANY WIRING!!!