Pag. 1/15

0CAR6IN019124_Manual_GLH110_Rev_0.3

GLH110 Glass

Temperature Controller

User Manual

1.

MAIN FEATURES

The

GLH110

Temperature Controller manages Wood Fireplaces and Boilers, for heating and domestic hot water production, with the

possibility to integrate it to a Gas Boiler.

Safety Rules

Read carefully the following safety regulations, in order to prevent accidents

damage to people and things.

Before working on the hydraulic plant, please be aware of the following:

Accident prevention measures

Environmental protection measures

National Institute for Work accidents measures

Recognized prevention measures

This manual is intended for qualified technical staff only

Electrical wiring and connection must be performed by qualified

technicians only

The first installation of the hydraulic plant must be performed expert

personnel

Declaration of Conformity

Regulations:

EN 60730-1 50081-1

EN 60730-1 A1 50081-2

TiEmme elettronica

06055 Marsciano (PG) Italy Tel.+39.075.874.3905; Fax.

+39.075.874.2239

info@tiemmeelettronica.it

Technical data

Supply:230 Vac 50 Hz

10%

Absorption:2,5 VA

Outputs Range:5A 250 Vac

Internal fuse:3,15 A

Mechanical Characteristics

Material: PA

Flush mount Installation:Incasso 3

Modules/ Wall

Dimensions:Flush mount: 132x68x50 mm

Degree of Protection:IP40

Installation conditions and Use

Operating Temperature: 0÷40 °C

Storage Temperature:0 ÷ 60 °C

Umidity: 85% @25°C

2.

INSTALLATION

Make sure that the Main Power Supply is OFF prior to installing the device

Install the product in a dry environment with proper climatic conditions

Insert a bipolar main switch compliying to local regulations

Avoid coupling the probe cables with these of power

Use for wiring, cables with conductors of appropriate section and in according the rules

Position the probes to detect correctly the temperature

Make sure the probe wires are placed away from direct/indirect flame

3.

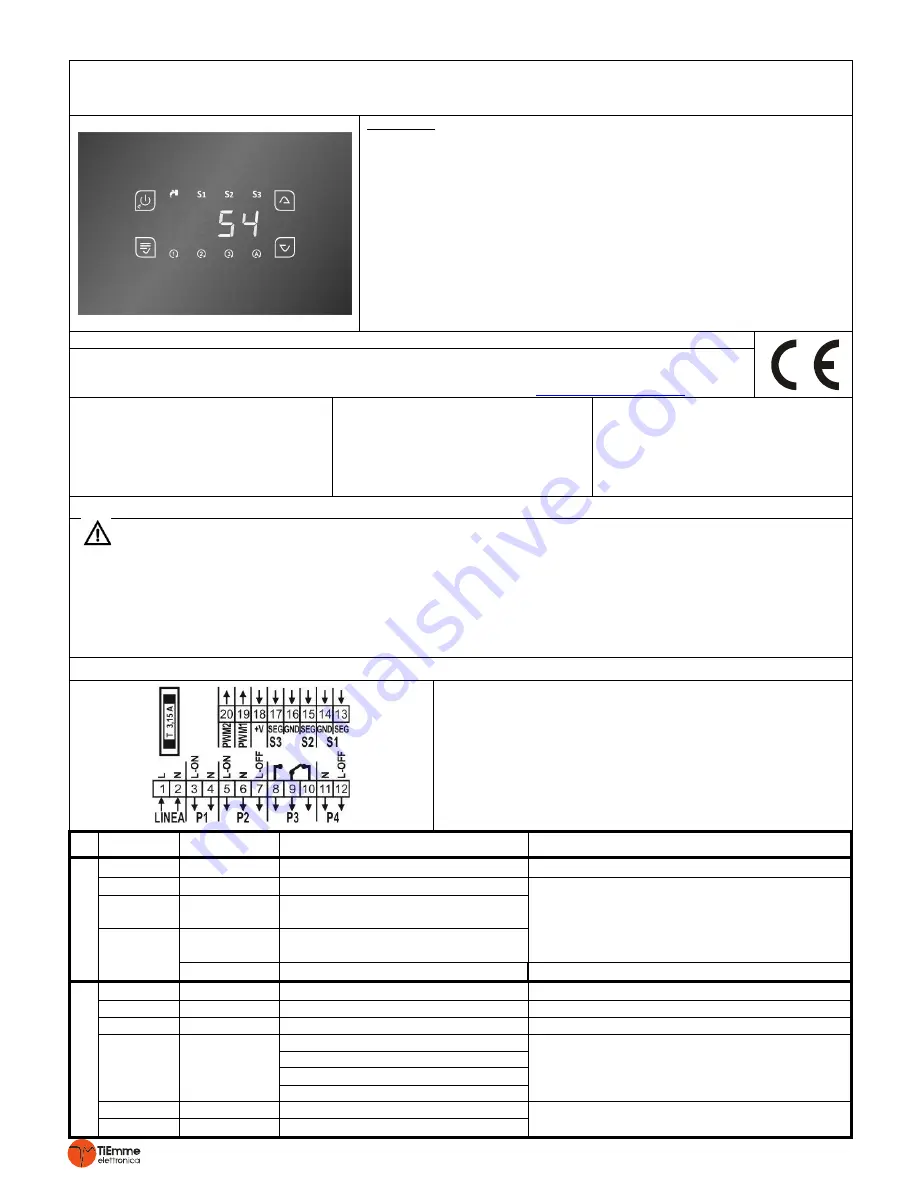

ELECTRICAL CONNECTIONS

All the probe inputs and command outputs are controlled

automatically according to the type of hydraulic/plumbing

plant selected.

For electrical connections

you must refer to Chapter 7 and the following paragraphs

concerning the hydraulic/plumbing schematic drawings.

Fig.2 –

Electrical connections

Code

Connectors

Device

Characteristics

INP

U

T

S

LINE

1 – 2

Voltage Supply

230 Vac 50 Hz

10%

S1

13 – 14

Fireplace Temperature Probe

Operating Range: -50°C ÷ 125 °C

NTC 10K Measure: -10 ÷ 110 °C

1°C

NTC 100K Measure: -10 ÷ 300 °C

1°C

PT 1000 Measure: -40 ÷ 300 °C

1°C

Flow switch contact ON/OFF

S2

15 – 16

Sanitary Boiler Probe / Buffer

Flow Switch

S3

16 – 17

Ambient Probe/Thermostat

Buffer, Manifold

16 – 17 – 18

Pressure Sensor

Operating Range: 0 ÷3 bar / 0 ÷ 3V

O

U

T

PU

T

S

P1

3 – 4

Pump 1

230 Vac 5A

P2

5 – 6 – 7

Diverter Valve / Pump 2

230 Vac 5A

P3

8 – 9 – 10

Boiler Integration Consent

Contact in exchange: COM.(9)-N.O.(8) - N.C.(10)

P4

11 - 12

Service = Thermostat

230 Vac 5A

Service = Grill

Combustion Air Shutter

Pump 2

PWM1

19 – 16 o 14

Control PWM1

0-5Vdc, Frequency 1Khz, Duty Cycle 0-100%

PWM2

20 – 16 o 14

Control PWM2