z

Install

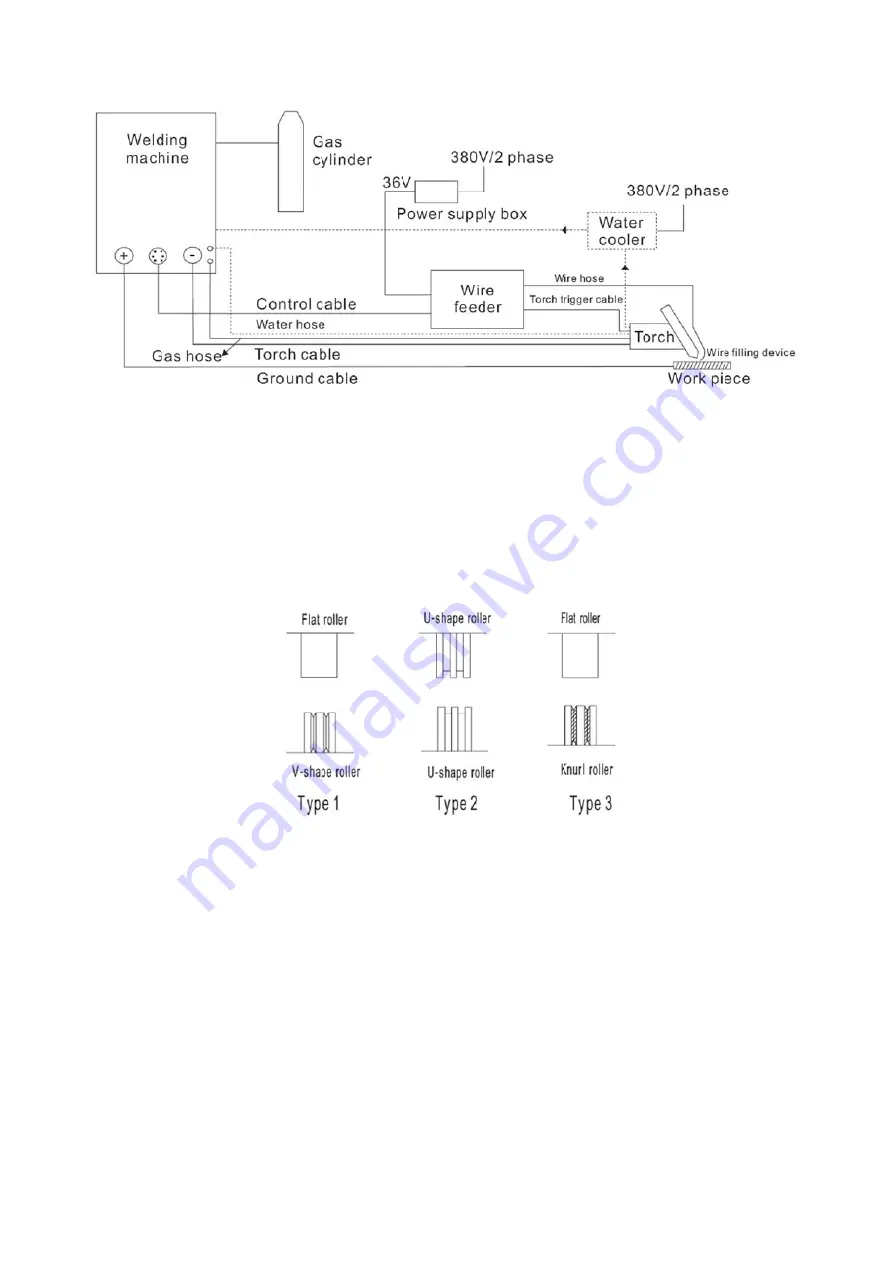

The proper

feed rollers

Type 1: for

Type 2: for

Type 3: for

Important!

wire crushe

increase th

Suitable pre

ation of wir

r wire feed ro

s as Fig. 3-5

hard wire, s

soft wire, su

flux-cored w

!

When use

ed, and the

e wire feedi

essures for

re feed rolle

ollers must b

-2:

such as carb

uch as alum

wire

pressure ha

wire coatin

ng resistanc

wires of diff

Fig. 3

ers

be chosen a

bon steel wir

minum and a

Fig. 3-5

andle to adju

g be damag

ce.

erent mater

3-5-1:

Instal

according to

re, stainless

luminum allo

5-2: Wire fee

ust wire fee

ged, and it

rials and diam

lation

the size and

s steel wire.

oys, also for

ed rollers

l roller press

will cause t

meters are a

d material of

r copper and

sure, too mu

he wearing

as shown in

f the wire. Ty

d copper allo

uch pressur

out of feed

Fig. 3-5-3.

ypes of wire

oy wire.

e will cause

rollers and

e

e

d

Summary of Contents for 320020-00001H

Page 1: ...TIG TIG Cold Wire Feeder ...