Tiger Chipper Shredder CS7-200H & CS7-270H Owners Manual (PART CS-M)

page 18

It is the retailers responsibility to ensure that this machine is correctly commissioned for use, and that the purchase

is registered with Stevens Outdoor Power Equipment, and the Engine is registered with the Honda Agency to

provide the owner with the full benefit of the warranty policy.

Product registration must be completed and returned to Stevens Outdoor Power Equipment. For registration info

you will require the machine serial number and customer details.

Your Honda Engine registration must be completed and returned to Power and Marine Ltd. For registration info,

please refer to the Honda Engine Owners Manual .

It is the Retailers Responsibility to Check the Following:

Final Assembly

Check all bolts for tightness including blades.

Operation

Instruct the owner/operator on operating procedures and techniques.

Safety

Instruct owner/operator on safety procedures.

Maintenance

Explain the maintenance requirements and the importance of following the

maintenance schedule to the owner/operator.

Manual

Emphasise the importance of reading and understanding the manual in full

before initial operation of the Tiger Chipper Shredder.

Commissioning Checklist & Registration

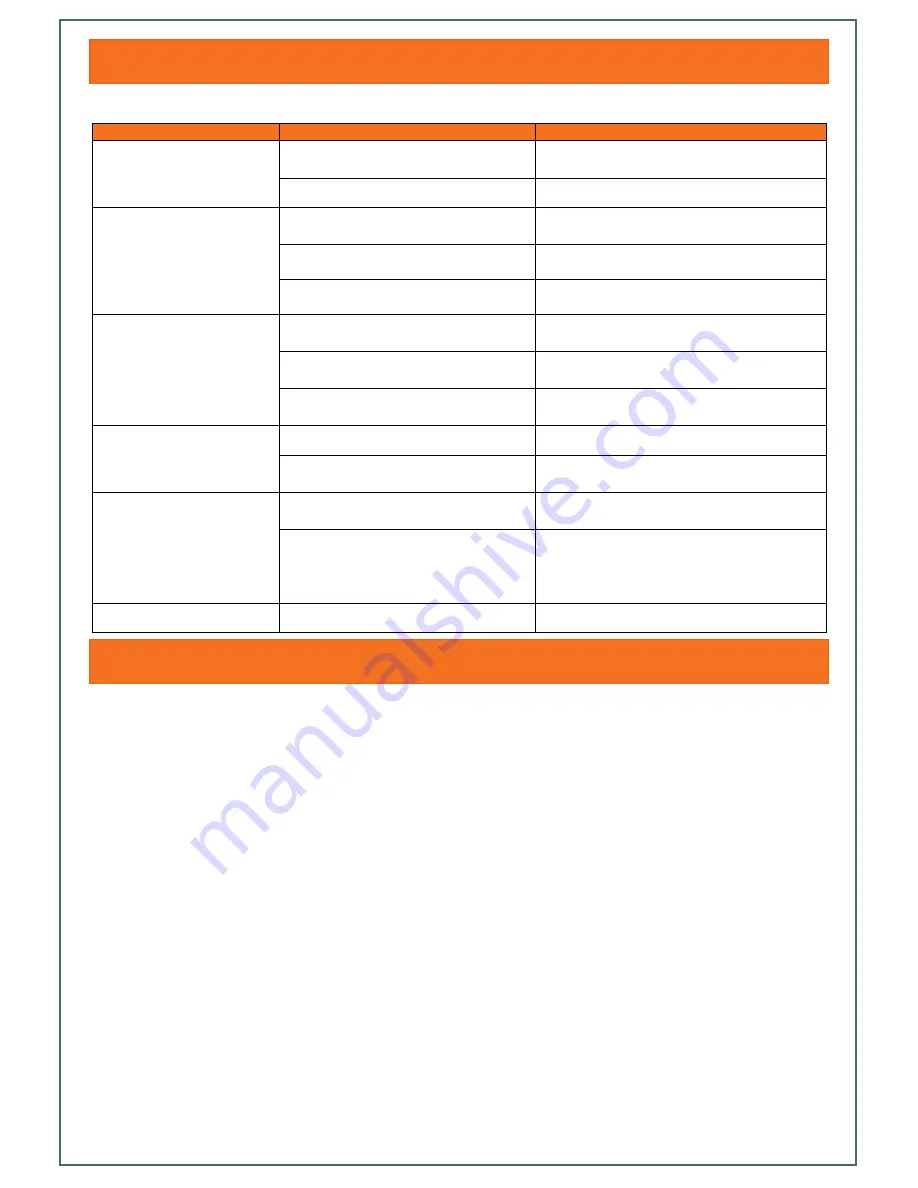

Trouble Shooting

Problem

Probable Cause

Suggested Remedies

Rotor does not turn

Obstructed discharge

Use branch or similar object to clear discharge

Plugged rotor

Clear rotor

Hard to feed chipper or

excessive power needed to

chip and shred

Obstructed discharge

Use branch or similar object to clear discharge

Dull chipper blades

Turn blade over to present new edge if there is

one, or remove for sharpening.

Improper blade clearance

Adjust clearance between anvil and blade to

2mm.

Chipper Shredder requires

excessive power or stalls

Obstructed discharge

Use branch or similar object to clear discharge

Plugged rotor

Clear rotor, feed material into shredder more

evenly

Green material will not discharge

Alternately feed dry material, or allow material

to dry

Drive belts squealing or

smoking

Plugged rotor

Clear rotor

Loose or worn belts

Adjust belt tension or replace belts if needed

Vibration while running

Drive head vibration

Check drive belts and pulleys for bad or worn

spots

Rotor out of balance

Inspect rotor for broken or missing chipper

blades and shredder knives

.

Repair if needed.

Check rotor to see if it wobbles.

Check to see if the rotor correctly assembled.

Engine dies or runs poorly

Engine problems

Contact local Honda dealer