MAINTENANCE

SIDE ROTARY

Maintenance Section 4-22

© 2014 Alamo Group Inc.

MAINTENANCE

BEARING INSTALLATION

1. Press upper bearing cup into the spindle

housing

2. Turn the spindle housing over and press in the

lower bearing cup.

3. Place the lower bearing cone in the bearing

cup. Next press the seal into the spindle

housing. The inner lip of the seal must be

DOWN, towards the bearing, so lubricant is

sealed inside the housing.

4. Install the spindle in the housing. Lightly press

the end of the spindle to seat the sp indle

against the bearing inner race.

5. Turn the spindle housing over (up position) and fill with Tiger Spindle Lubricant (part number 06540000) to

the top edge of the upper bearing cup.

6. Support the bottom of the spindle and press the upper bearing cone and bearing adjustment sleeve onto

the spindle.

NOTE:

The spindle housing must turn freely when seating the bearing cone and sleeve.

7. Press the two upper seals into the spindle housing. The inner lip of the seals must be UP, away from the

bearing, so excess lubricant can escape.

8. Install the bearing adjustment nut (thin nut) so there is 1-1/6” clearance between the nut and the sleeve.

Install the jam washer, placing the tab into the key-way. Install the bearing lock nut (thin nut) and hand

tighten against jam washer and adjustment nut. See the following section for bearing adjustment.

BEARING ADJUSTMENT

1. Clamp the bottom end of the spindle securely in

a vise so the spindle housing turns freely.

2. Position a magnetic base dial indicator on the

outer diameter of the spindle housing. Locate

the end of the dial indicator against the flat end

of the spindle shaft. The dial indicator will now

measure accurately bearing end play.

3. Tighten the bearing adjustment nut until there is

0.012 inch movement when the spindle housing

is pried upward away from the vise jaws.

4. When there is 0.012 inch free play between the

spindle and housing, install the bearing lock nut

(thick nut). Hold the adjusting nut securely and

tighten the lock nut to 300 ft. lbs. of torque.

5. After the lock nut is tightened, there must be 0.001 inch to 0.003 inch of free play when lightly prying up on

the spindle housing.

If the end play is correct, 0.001 inch to 0.003 inch, bend tabs up on jam washer to prevent the lock nut from

loosening.

If the end play is NOT correct, loosen the lock nut and turn the adjustment nut as required and re-tighten the

lock nut. Repeat first part of step 5.

Summary of Contents for JD5075E T4F

Page 4: ......

Page 6: ......

Page 7: ...SAFETY SECTION...

Page 18: ...Side Rtry Safety Section 1 12 SAFETY SAFETY...

Page 27: ...Side Rtry Safety Section 1 21 SAFETY SAFETY 00756059 MOWER DECK 34852 HYDRAULIC TANK...

Page 30: ...Side Rtry Safety Section 1 24 SAFETY SAFETY...

Page 31: ...Assembly Section 2 1 ASSEMBLY SECTION JD 5075E T4F SIDE ROTARY...

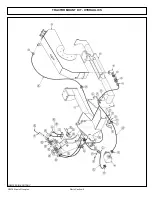

Page 44: ...ASSEMBLY Assembly Section 2 14 SIDE MOWER HYDRAULIC DIAGRAM ASM C 0090 JD5075E...

Page 49: ...Operation Section 3 1 2013 Alamo Group Inc OPERATION SECTION...

Page 90: ...OPERATION SIDE ROTARY Operation Section 3 42 2014 Alamo Group Inc OPERATION...

Page 91: ...Maintenance Section 4 1 2014 Alamo Group Inc MAINTENANCE SECTION...

Page 114: ...MAINTENANCE SIDE ROTARY Maintenance Section 4 24 2014 Alamo Group Inc MAINTENANCE...

Page 115: ...PARTS SECTION JD5075E T4F SIDE ROTARY...

Page 117: ...PARTS ORDERING GUIDE 2019 Alamo Group Inc Parts Section 3 JD5075E SIDE ROTARY...

Page 118: ...TRACTOR MOUNT KIT 2019 Alamo Group Inc Parts Section 4 JD5075E SIDE ROTARY...

Page 120: ...TRACTOR MOUNT KIT HYDRAULICS 2019 Alamo Group Inc Parts Section 6 JD5075E SIDE ROTARY...

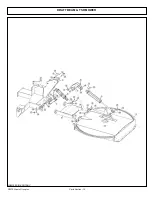

Page 124: ...DRAFT BEAM TSR MOWER 2019 Alamo Group Inc Parts Section 10 JD5075E SIDE ROTARY...

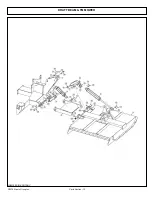

Page 126: ...DRAFT BEAM TM MOWER 2019 Alamo Group Inc Parts Section 12 JD5075E SIDE ROTARY...

Page 129: ...NOTES 2019 Alamo Group Inc Parts Section 15 JD5075E SIDE ROTARY...

Page 133: ...PARTS SECTION COMMON SIDE ROTARY...

Page 134: ...NOTES...

Page 137: ...PARTS ORDERING GUIDE 2014 Alamo Group Inc Parts Section 6 5 COMMON SIDE ROTARY...

Page 138: ...CABLE DRAFT BEAM ASSEMBLY 2014 Alamo Group Inc Parts Section 6 6 COMMON SIDE ROTARY...

Page 140: ...COMBO DRAFT BEAM ASSEMBLY 2014 Alamo Group Inc Parts Section 6 8 COMMON SIDE ROTARY...

Page 142: ...60IN SIDE CABLE TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 10 COMMON SIDE ROTARY...

Page 144: ...72IN SIDE CABLE TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 12 COMMON SIDE ROTARY...

Page 146: ...60IN SIDE COMBO TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 14 COMMON SIDE ROTARY...

Page 148: ...72IN SIDE COMBO TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 16 COMMON SIDE ROTARY...

Page 150: ...60IN SIDE TM CHAIN GUARDS 2014 Alamo Group Inc Parts Section 6 18 COMMON SIDE ROTARY...

Page 152: ...72IN SIDE TM CHAIN GUARDS 2014 Alamo Group Inc Parts Section 6 20 COMMON SIDE ROTARY...

Page 154: ...60IN SIDE TSR ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 22 COMMON SIDE ROTARY...

Page 156: ...60IN SIDE TSR REAR GUARDS 2014 Alamo Group Inc Parts Section 6 24 COMMON SIDE ROTARY...

Page 158: ...SIDE ROTARY CASTER WHEEL ASSEMBLY 2014 Alamo Group Inc Parts Section 6 26 COMMON SIDE ROTARY...

Page 162: ...TM MOWER SPINDLE ASSEMBLY 2014 Alamo Group Inc Parts Section 6 30 COMMON SIDE ROTARY...

Page 164: ...TSR MOWER SPINDLE ASSEMBLY 2014 Alamo Group Inc Parts Section 6 32 COMMON SIDE ROTARY...

Page 166: ...ROTARY MOTOR BREAKDOWN 2014 Alamo Group Inc Parts Section 6 34 COMMON SIDE ROTARY...

Page 168: ...60IN TSR ROTARY MOTOR BREAKDOWN 2014 Alamo Group Inc Parts Section 6 36 COMMON SIDE ROTARY...

Page 170: ...FRONT HYDRAULIC PUMP BREAKDOWN 2014 Alamo Group Inc Parts Section 6 38 COMMON SIDE ROTARY...

Page 191: ...BRAKE VALVE HYDRAULIC SCHEMATIC 2014 Alamo Group Inc Parts Section 6 59 COMMON SIDE ROTARY...

Page 195: ...SWITCH BOX SCHEMATIC 2014 Alamo Group Inc Parts Section 6 63 COMMON SIDE ROTARY...

Page 196: ...NOTES 1 2014 Alamo Group Inc Parts Section 6 64 COMMON SIDE ROTARY...

Page 197: ...WARRANTY SECTION Warranty Section 7 1...

Page 198: ......

Page 202: ...Printed in USA Tiger Corporation...