MAINTENANCE

SIDE ROTARY

Maintenance Section 4-23

© 2014 Alamo Group Inc.

MAINTENANCE

DAILY MAINTENANCE SCHEDULE

The following services should be performed daily or every 8 hours of service, following the detailed

maintenance instructions in the operator’s manual.

_______ Pump Driveshaft: Check for end play in driveshaft / coupler and lubricate at zerks.

_______ Crankshaft adapter: If equipped with rubber grommets check condition, replace if missing or

damaged.

_______ Pivot points: Inject grease until it appears at ends.

_______ Hydraulic fittings: Check for leaks with paper or cardboard. Tighten fittings or replace hoses

immediately

_______ Knives: Inspect for missing or damaged knives, change (only complete sets) as needed.

_______ Belts: Check/Tighten/Replace belts as needed.

_______ Mainframe/Deck: Unless otherwise specified retorque bolts according to torque specifications in this

section.

_______ Hydraulic Fluid Level: Add, if required, per fluid recommendations.

_______ Rear Flail Drive, Bearing Flange and Shaft Couplers (if applicable): Grease as instructed in the

detailed Maintenance Section.

_______ Cutter Shaft and Ground Roller: Grease as instructed in the detailed Maintenance Section.

Service performed by:________________________________Date:____/____/____ Hour

Meter:_____________________

Maintenance Section

**This page may be copied and used as part of the daily maintenance routine.

Summary of Contents for JD5075E T4F

Page 4: ......

Page 6: ......

Page 7: ...SAFETY SECTION...

Page 18: ...Side Rtry Safety Section 1 12 SAFETY SAFETY...

Page 27: ...Side Rtry Safety Section 1 21 SAFETY SAFETY 00756059 MOWER DECK 34852 HYDRAULIC TANK...

Page 30: ...Side Rtry Safety Section 1 24 SAFETY SAFETY...

Page 31: ...Assembly Section 2 1 ASSEMBLY SECTION JD 5075E T4F SIDE ROTARY...

Page 44: ...ASSEMBLY Assembly Section 2 14 SIDE MOWER HYDRAULIC DIAGRAM ASM C 0090 JD5075E...

Page 49: ...Operation Section 3 1 2013 Alamo Group Inc OPERATION SECTION...

Page 90: ...OPERATION SIDE ROTARY Operation Section 3 42 2014 Alamo Group Inc OPERATION...

Page 91: ...Maintenance Section 4 1 2014 Alamo Group Inc MAINTENANCE SECTION...

Page 114: ...MAINTENANCE SIDE ROTARY Maintenance Section 4 24 2014 Alamo Group Inc MAINTENANCE...

Page 115: ...PARTS SECTION JD5075E T4F SIDE ROTARY...

Page 117: ...PARTS ORDERING GUIDE 2019 Alamo Group Inc Parts Section 3 JD5075E SIDE ROTARY...

Page 118: ...TRACTOR MOUNT KIT 2019 Alamo Group Inc Parts Section 4 JD5075E SIDE ROTARY...

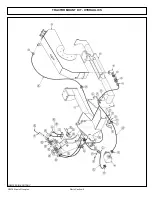

Page 120: ...TRACTOR MOUNT KIT HYDRAULICS 2019 Alamo Group Inc Parts Section 6 JD5075E SIDE ROTARY...

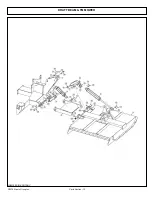

Page 124: ...DRAFT BEAM TSR MOWER 2019 Alamo Group Inc Parts Section 10 JD5075E SIDE ROTARY...

Page 126: ...DRAFT BEAM TM MOWER 2019 Alamo Group Inc Parts Section 12 JD5075E SIDE ROTARY...

Page 129: ...NOTES 2019 Alamo Group Inc Parts Section 15 JD5075E SIDE ROTARY...

Page 133: ...PARTS SECTION COMMON SIDE ROTARY...

Page 134: ...NOTES...

Page 137: ...PARTS ORDERING GUIDE 2014 Alamo Group Inc Parts Section 6 5 COMMON SIDE ROTARY...

Page 138: ...CABLE DRAFT BEAM ASSEMBLY 2014 Alamo Group Inc Parts Section 6 6 COMMON SIDE ROTARY...

Page 140: ...COMBO DRAFT BEAM ASSEMBLY 2014 Alamo Group Inc Parts Section 6 8 COMMON SIDE ROTARY...

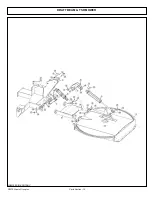

Page 142: ...60IN SIDE CABLE TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 10 COMMON SIDE ROTARY...

Page 144: ...72IN SIDE CABLE TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 12 COMMON SIDE ROTARY...

Page 146: ...60IN SIDE COMBO TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 14 COMMON SIDE ROTARY...

Page 148: ...72IN SIDE COMBO TM ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 16 COMMON SIDE ROTARY...

Page 150: ...60IN SIDE TM CHAIN GUARDS 2014 Alamo Group Inc Parts Section 6 18 COMMON SIDE ROTARY...

Page 152: ...72IN SIDE TM CHAIN GUARDS 2014 Alamo Group Inc Parts Section 6 20 COMMON SIDE ROTARY...

Page 154: ...60IN SIDE TSR ROTARY MOWER 2014 Alamo Group Inc Parts Section 6 22 COMMON SIDE ROTARY...

Page 156: ...60IN SIDE TSR REAR GUARDS 2014 Alamo Group Inc Parts Section 6 24 COMMON SIDE ROTARY...

Page 158: ...SIDE ROTARY CASTER WHEEL ASSEMBLY 2014 Alamo Group Inc Parts Section 6 26 COMMON SIDE ROTARY...

Page 162: ...TM MOWER SPINDLE ASSEMBLY 2014 Alamo Group Inc Parts Section 6 30 COMMON SIDE ROTARY...

Page 164: ...TSR MOWER SPINDLE ASSEMBLY 2014 Alamo Group Inc Parts Section 6 32 COMMON SIDE ROTARY...

Page 166: ...ROTARY MOTOR BREAKDOWN 2014 Alamo Group Inc Parts Section 6 34 COMMON SIDE ROTARY...

Page 168: ...60IN TSR ROTARY MOTOR BREAKDOWN 2014 Alamo Group Inc Parts Section 6 36 COMMON SIDE ROTARY...

Page 170: ...FRONT HYDRAULIC PUMP BREAKDOWN 2014 Alamo Group Inc Parts Section 6 38 COMMON SIDE ROTARY...

Page 191: ...BRAKE VALVE HYDRAULIC SCHEMATIC 2014 Alamo Group Inc Parts Section 6 59 COMMON SIDE ROTARY...

Page 195: ...SWITCH BOX SCHEMATIC 2014 Alamo Group Inc Parts Section 6 63 COMMON SIDE ROTARY...

Page 196: ...NOTES 1 2014 Alamo Group Inc Parts Section 6 64 COMMON SIDE ROTARY...

Page 197: ...WARRANTY SECTION Warranty Section 7 1...

Page 198: ......

Page 202: ...Printed in USA Tiger Corporation...