10-4

ZR Owner’s Manual

OM_ZR_0913RevA

CHAPTER 10: WHEEL LOCKS

Replacing

Tools Needed:

• 3/16” Allen Wrench

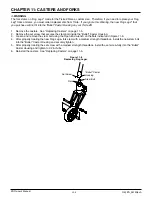

1. Loosen the two Allen screws that secure the wheel lock clamp to the frame. See Figure 10-4.

2. Slide the wheel lock out of the clamp.

3. Slide the new Uni-Lock into the wheel lock clamp, but do not tighten the Allen screws.

4. Follow the procedures under “Uni-Lock - Adjusting” on page 10-3 to position and secure the new wheel lock.

Changing the Uni-Lock from the push to the pull position

Tools Needed:

• 5/32” Allen Wrench

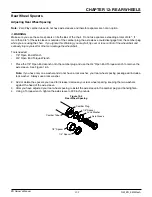

The Uni-Lock wheel lock can be set up so that you either pull the handle to engage the lock or push the handle to

engage the lock. To determine which setup you have, locate the small Socket Head Cap screw in the wheel lock

handle base. If it is in the upper position (see Figure 10-5), the Uni-Lock is set to the “Pull to Lock” position. If it is in

the lower position (see Figure 10-6), the Uni-Lock is set to the “Push to Lock” position.

Figure 10-6

push to Lock position

Figure 10-5

pull to Lock position

Socket Head

Cap Screw

Socket Head

Cap Screw

You can change the operation from pull to push or vice versa as follows:

1. Remove the Socket Head Cap screw and reposition it to either the “Pull to Lock” or “Push to Lock” position, as

desired. See Figure 10-7.

2. Securely tighten the Socket Head Cap screw.

Figure 10-7

Repositioning the Handle

Push to Lock

Position

Pull to Lock

Position

Repositioning the Handle of the Uni-Lock Wheel Lock

Six (6) handle positions are achievable using the Uni-Lock. See Figures 10-8 through 10-11. Each handle position

can be used as either a “Pull to Lock” or a “Push to Lock” (see “Changing the Uni-Lock From the Push to the Pull

Position” on pages 10-4 and 10-5), resulting in 12 possible Uni-Lock setups.

Figures 10-8 through 10-11 show the handle in both the engaged (locked) and disengaged (unlocked) positions.

Study the Figures to determine which handle configuration will work best for you. Follow the directions below to

reconfigure your handle to the desired configuration.

![Dietz AS[01] Operating Instructions Manual preview](http://thumbs.mh-extra.com/thumbs/dietz/as-01/as-01_operating-instructions-manual_2495921-01.webp)