K10-COMPACT-OP-EN

- 17 -

FLUSH RECOVERY TANK:

1. Rinse the Recovery Tank after every use

(A)

. This will prevent heavy build-up on the

bottom of the Tank, foul odors as well as

clogging of the Drain Hose

(SEE BELOW)

.

2. Remove Drain Hose

(B)

and open to allow for

drainage of the Recovery Tank

(SEE BELOW)

.

3. Flush Recovery Tank with water hose.

4. After rinsing, reattach the Drain Hose

(B)

on hook

(SEE ABOVE)

.

NOTICE

Keep water off of Control Panel.

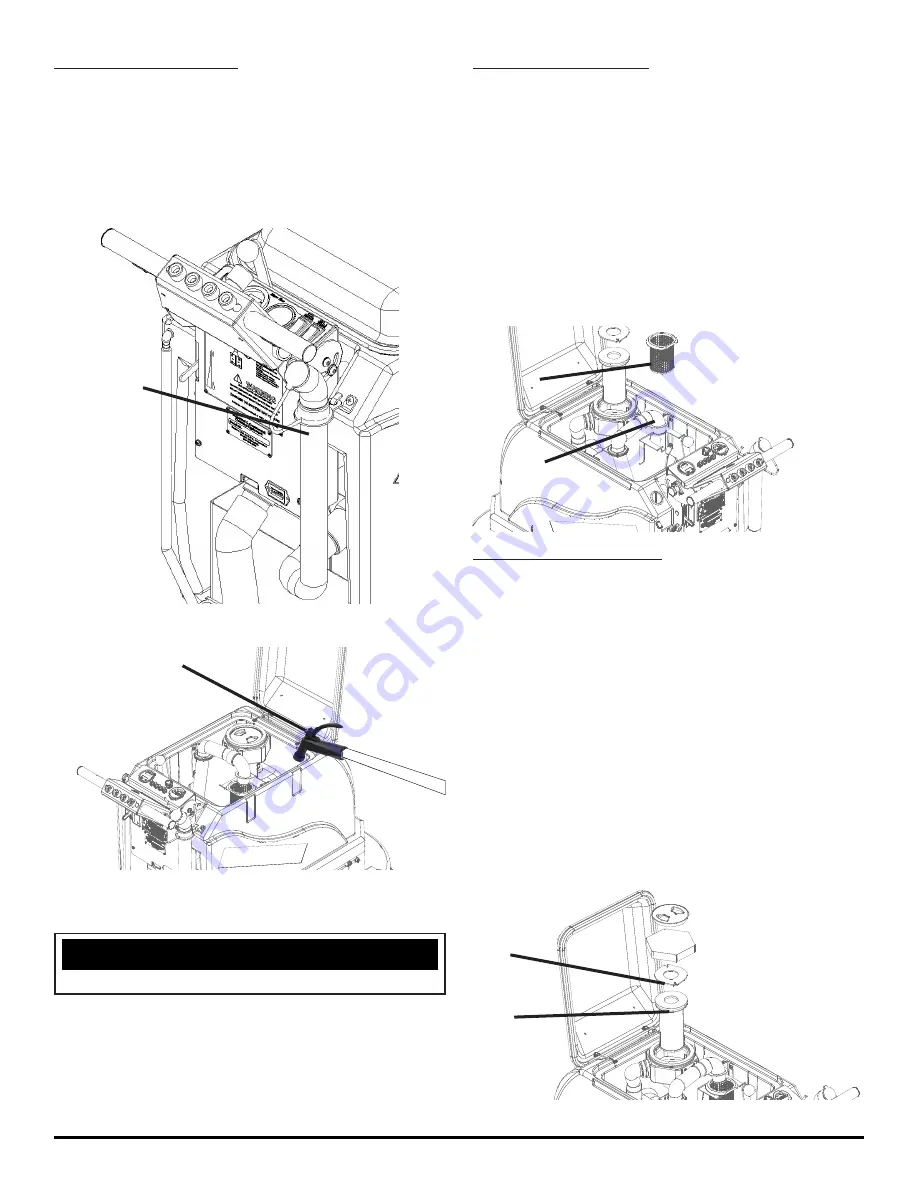

CLEAN “DRAIN SAVER”:

With Recovery Lid open and Tank fully drained:

1. Remove 2'' Squeegee Intake Hose

(A)

from

“Drain Saver” strainer

(B)

(SEE BELOW)

.

2. Remove stainless screen and dispose of debris.

3. Rinse screen with fresh water from the

outside while holding the screen upside

down. This will allow for better cleaning.

4. Replace the screen into the bracket.

5. Replace 2'' Squeegee Intake Hose.

CLEAN VACUUM SCREEN:

With Recovery Lid open and Tank fully drained:

1. Remove Vacuum Screen retaining

clip

(C)

(SEE BELOW)

.

2. Pull Vacuum Screen and float ball

assembly

(D)

off of the Vacuum box.

3. Rinse with hot water.

4. Dry thoroughly.

5. Replace the Vacuum Screen onto box.

6. Replace and tighten retaining clip.

A

B

B

A

C

D