TIMBERWOLF

TW SX200

23

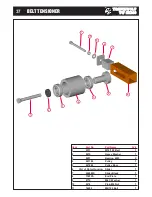

GREASE THE ROLLER SPLINE AND BEARING

SERVICE INSTRUCTIONS

NOTE: This should be done every 50 hours. In dirty or

dusty conditions or during periods of hard work it should be

done more frequently. If the slides become dry the top roller

will tend to hang up and the pulling-in power of the roller

will be much reduced. Excessive wear will ensue.

1.

Remove the top roller box guard.

2.

Remove the nearside roller box guard.

3.

Apply multipurpose grease directly to the slide surfaces

indicated (B).

DO NOT USE GRAPHITE BASED GREASE.

4.

Refit both the roller box guards.

1.

Remove the top roller box guard.

2.

Locate the grease nipple indicated (A).

3.

Use a pump action grease gun to apply a generous

amount of grease to each roller drive.

DO NOT USE GRAPHITE BASED GREASE.

3.

Refit the top roller box guard.

NOTE: This should be done regularly. In dirty and dusty conditions or during periods of hard

work it should be weekly. If the bearings and splines are allowed to run dry premature wear will

occur resulting in a breakdown and the need for replacement parts. This failure is not warranty.

Early signs of insufficient grease includes squeaking or knocking rollers.

1. Remove the drum housing guard, situated on the offside of

the machine.

2. Apply two pumps of grease to the bearing (A) taking care

not to over grease.

3. Refit guard.

1. Turn the discharge tube to point forward of the machine.

2. Using a 24 mm spanner remove the two M16 bolts

clamping the drum housing shut.

3. Carefully lift the drum housing until it rests on its stop.

4. Apply two pumps of grease (B) to the bearing taking care

not to over grease.

5. Lower the top of the drum housing and reinstall the two M16

bolts.

6. Torque these to 65lbft.

B

Both bearings need regularly greasing.

A

B

A

GREASE THE DRUM BEARINGS

GREASE THE ROLLER BOX SLIDES

Summary of Contents for TW SX200

Page 28: ...TIMBERWOLF TW SX200 27 IDENTIFICATION PLATE EXAMPLE...

Page 36: ...Blank page...