UM-11

Cobot Transfer Unit

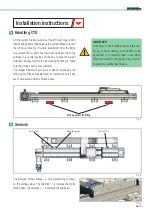

Fig. 5

Handling CTU

Lift the system, making sure to set the lift truck forks on both

load bearing beams that make up the system. Make sure that

the lift truck forks are in points equidistant from the fixing

crosspieces that support the load-bearing beam. Place the

carriage in a central position on the axis to keep the weight

balanced. Always monitor the load during handling to make

sure that it does not tip over suddenly.

The images below will give you an idea for positioning the

lifting points. Please consider them as indications only. They

are to help explain what is written above.

The direction of the carriage -/+ for programming is shown

on the carriage sides. The direction “-” is towards the motor

driving head, the direction “+” is towards the idle head.

Pick up points for lifting

IMPORTANT!

If the mass of the individual pieces totals over

20 kg, to avoid damage or accidents to the

operator(s), it is recommended to use lifting

machines suited to the specific use and ma-

neuvered by qualified technicians.

Installation instructions

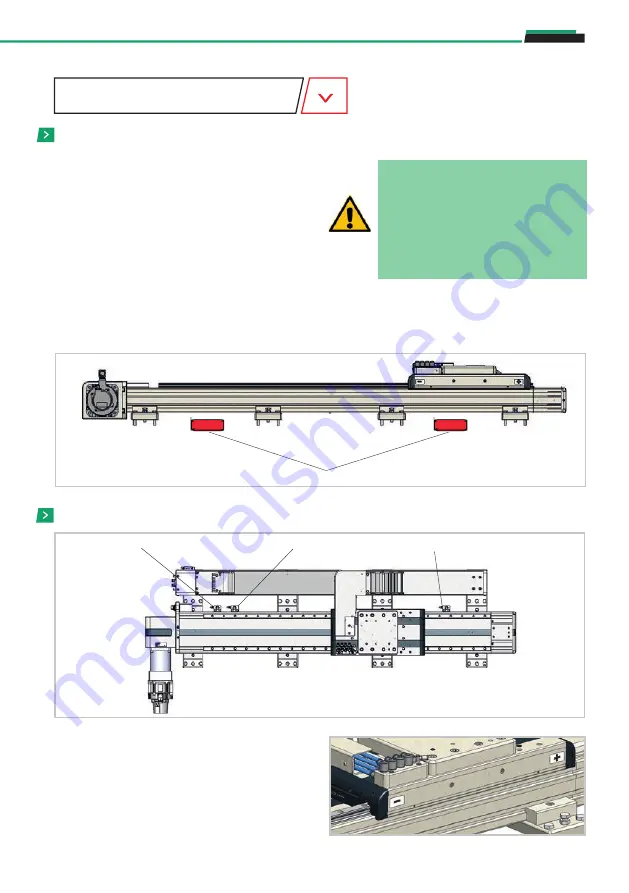

Fig. 6

Fig. 7

Sensors

Limit switch 1

Machine homing

Limit switch 2

Summary of Contents for ROLLON CTU 220-1I

Page 2: ......

Page 44: ...UM 42 Notes Notes...

Page 45: ...UM 43 Cobot Transfer Unit Notes...

Page 46: ...UM 44 Notes Notes...

Page 47: ......