UM-18

4 Installation instructions

Notes on lubrication

CTU features rails with self-lubricating recirculating ball bear-

ings.

Carriages with recirculating ball bearings also have a retain-

ing cage that eliminates the “steel on steel” contact between

adjacent rolling bodies and prevents misalignments of theses

parts in the circuits.

Lubricant tanks are installed on the fronts of carriages with

recirculating ball bearings. These small reservoirs release the

right quantity of lubricant in the areas where the ball bearings

support the applied loads.

This system guarantees long maintenance intervals: every

5000 km or once a year, whichever quantity is reached first.

■

Insert the dispensing nozzle into the specific lubricator.

■

Type of lubricant: class NLGI 2 lithium soap based grease.

■

More frequent lubrication is necessary for heavy duty

applications or difficult environmental conditions.

For more information, contact Rollon.

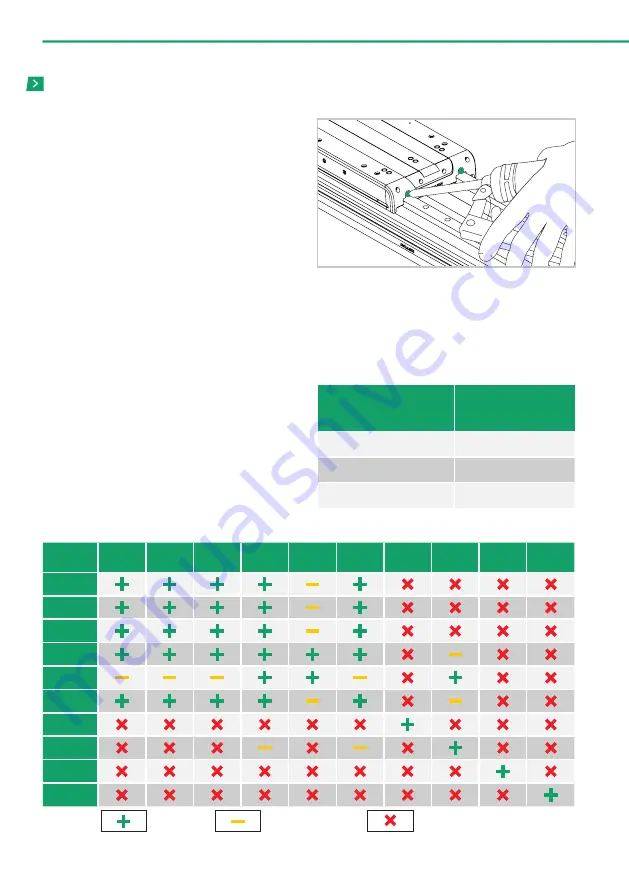

Quantity of grease necessary for re-lubricating each of the 4 blocks.

Type

Quantity

[cm

3

]

CTU130-1I

0.7

CTU160-1I

1.4

CTU220-1I

2.4

Lithium

Calcium

Lithium

Calcium

Lithium

Complex

Calcium

Complex

Calcium

Complex

Sulfonate

Aluminum

Complex

Polyurea

Bentone

Sodium

Lithium

Calcium

Lithium

Calcium

Lithium

Complex

Calcium

Complex

Calcium

Complex

Sulfonate

Aluminum

Complex

Polyurea

Bentone

Sodium

Grease compatibility

Compatible

Compatible in certain

Proportions

Not compatible

Fig. 26

Tab. 7

Summary of Contents for ROLLON CTU 220-1I

Page 2: ......

Page 44: ...UM 42 Notes Notes...

Page 45: ...UM 43 Cobot Transfer Unit Notes...

Page 46: ...UM 44 Notes Notes...

Page 47: ......