75 of 90

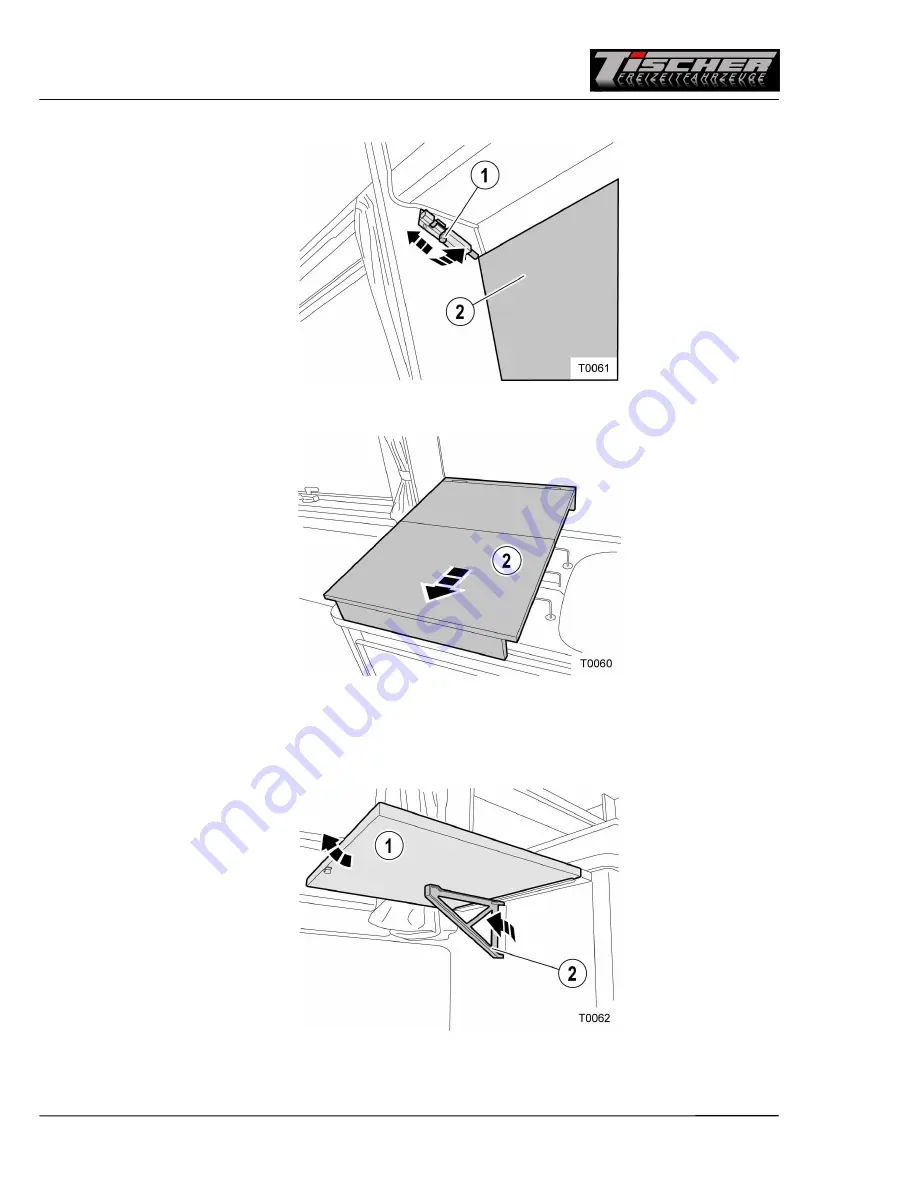

9.2 Hob cover

In order to fold down the cover for the hob, hold cover

2

, loosen locking mechanism

1

and fold down

cover

2

. In order to fold the cover up, proceed in reverse order.

9.3 Extending the working area (special equipment)

In order to unfold the working area extension

1

, lift working area

1

and pivot support

2

to the left. In

order to fold working area

1

down, proceed in reverse order.