36

4)

The turnstile to be energized;

5)

Zero position setting button on magnetic sensor board to be pushed and hold for at least 1

second, then to be released (make sure that the button pressure force does not bend the

board);

6)

After the button on the magnetic sensor board is released the zero position LED to be lit;

7)

Presence of signals of rotation angle changing, speed and zero position on controller PCB

201 - terminals: IN5, IN6, IN7, IN8. During

blade opening and closing:

- IN5, IN6

–

should exchange winks.

- IN7

–

is lit brightly if the blade is not moved

or is moved slowly. Brightness is decreased if

blade is rotated rapidly.

-

IN8

–

to be lit in just set zero position;

8)

Turnstile to be deenergized;

9)

Motor to be connected to PCB 201, terminals

MOT1;

10)

The turnstile to be energized;

11)

Turnstile operation to be checked

12)

New zero position setting is completed

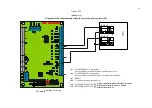

Leaf initial position calibration (Fig.21).

1)

The initial position setting button on the magnetic sensor board to be pushed (care must be

exercised to avoid the board bending due to the button pushing force);

2)

The new leaf initial position to be set;

3)

The button to be released;

4)

After the button on the magnetic sensor board is released the initial position LED to be lit;

5)

The presence of turning angle, speed and initial position change signals on controller

PCB201 to be checked

–

terminals: IN5, IN6, IN7, IN8. When the leaf is turned:

- IN5, IN6 to be exchanged winks.

- IN7 is lit brightly when leaf is no turned or turned slowly. When it is turned quickly then

bright will be reduced,

- IN8 to be lit only in the set initial position;

6)

The new initial position calibration The new initial position setting is completed.is

completed

Fig. 21

–

General view of the «JETPAN»turnstile magnetic sensor

Fig. 20

–

Turnstile blade in zero position

(access way is open)

Gap

between magnetic axis and

magnetic sensor

Top view of the installed magnetic

sensor

Layout of board over

magnetic axis