Barrier cabinet

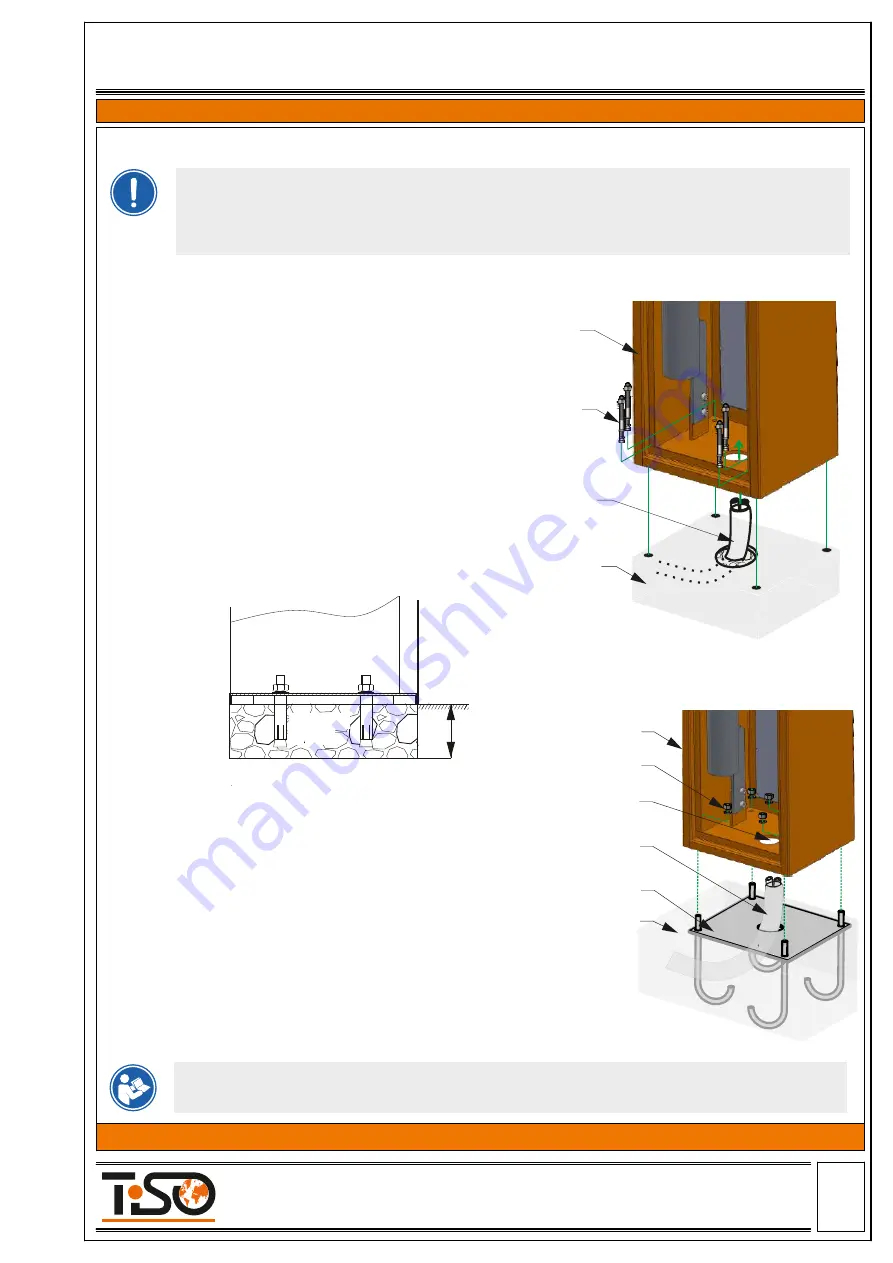

Concrete

base

Corrugated pipe for

communications

Anchor redibolt

М12х165

Concreted

pit

Bottom

plate

Corrugated pipe for

communications

Washer and

nut (4 pairs)

Communication

input

Cabinet

Concreting to be carried out in accordance with existing standards

The required electrical cables must be routed out of the concrete base.

џ

Place the barrier cabinet on the concreted bottom

plate

fix

and

with nuts.

џ

Level the

horizontally with the help of

bottom plate

the building level;

џ

Concrete the

;

bottom plate

џ

Install a corrugated pipe for communications for

laying electrical cables;

џ

Dig a pit for the

;

bottom plate

Option 2 - Laying the bottom plate for foundation

4) The Boom Barrier cabinet to be installed and anchor

nuts to be screwed.

3)

The cabinet to be oriented correctly, and levelled by

means of builder's level, anchor (M12x165) holes for

high performance concrete expansion to be marked and

drilled along the perimeter.

2) The barrier cabinet is fixed to the foundation by

means of anchor bolts. The depth of concreting depends

on the softness of soil and on the depth of soil freezing

(160–500 mm).

1) Dig the ground for concrete base, prepare the

corrugated hoses necessary for making connections for

the subsequent routing of cables in them (the required

number of channels depends on the type of installation

and the connected accessories).

Option 1 -Cabinet fastening

There are two ways to mount a barrier cabinet on the site:

It is recommended to install barrier cabinet in such a way that cabinet door to be opened from the

protected area.

The ground on the installation site shall be sufficiently stable for installation of boom barrier. If the

stability of the soil is unsatisfactory, increase the depth of pit as recommended by the specialists.

6.3 Preparation of bottom plate and installation of barrier cabinet

150-500

Cabinet

±0,000 R.s.l.

Concrete

base

Page

-12-

Size А4

Installation and Operation Manual

Revision 1.0 2021

ROAD BLOCKING SYSTEMS

Office and Production site:

Tel.:

+380 (44) 291-21-11

14 Promyslova str., 02088, Kyiv, Ukraine,

Fax:

+380 (44) 291-21-02

E-mail:

sales@tiso.global www.tiso.global

BOOM BARRIER OPTIMUS