17 AUIA.123.00.00.00.00-05 OM

2.2.3 The turnstile is installed in the following order:

–

inspect the turnstile for integrity, absence of visual damages and defects;

–

verify the turnstile’s completeness;

–

prepare installation site for mounting of ready-to-install turnstile: surface should be plain, hard and

without defects (corrugations, overlaps etc.);

–

protective ducts or conduits should be laid to the center of the turnstile’s rotor and to installation

sites of power supply units and to control sites to pull power and control cables of the turnstile;

–

mark the hole drilling places and check the marking according to the Appendix A. For this

purpose it is necessary to install the turnstile rotor and enclosures and make sure that the holes on

flanges match the floor or foundation holes. Modify the marking, if required.

The turnstile should be installed and fixed only after all the turnstile electric connection cables are

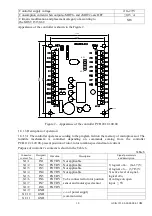

pulled. For access to fixation holes (see the Figure 1) it is necessary to remove sheeting, fix the

turnstile by means of Redibolt (anchor with jacket and screw) and make sure that the installed turnstile

is stable;

–

earthen the turnstile, connect power cable to the turnstile and control panel according to the wiring

diagram (see the Appendix C).

After the required installation sheeting should be placed back.

2.3 Preparation for use

2.3.1 Commissioning instructions

Prior to energizing of the turnstile:

1) make sure of proper connection and good condition of all connecting cables;

2) clear the area of the turnstile’s blades rotation from foreign particles.

3) check revolving of rotor: rotor with blades should revolve smoothly and after revolving to 120° it

should be locked.

When mains cable of power supply unit is connected to the network the flag rotation is locked. The

turnstile is set in initial state. Flag with blades is locked from rotation in both directions and access

between enclosures is barred by one of the blades.

The turnstile is set in initial state: entry and exit LED displays are red («

›‹

» is lit)

1

.

2.3.2 Required inspections

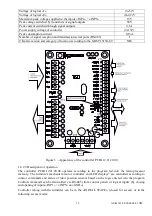

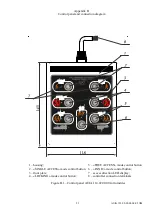

2.3.2.1 When rotor turnstile is commissioned as part of Access Control System or when it is controlled

by means of control panel (complete with reader racks and LED display panel) it is necessary to

perform inspections specified in the Table 9. During inspections the wiring diagram according to the

Appendix C and the control panel according to the Appendix B should be used.

Table 9

Operating Mode

Mode Setting

LED Display

1

Functional Check

1 Turnstile is closed

in both directions

(initial state)

–

Red LED display is lit

Make sure that rotor can’t be

rotated in any direction

2 Single access in

one direction

Push the

«SINGLE» access

button to access

in chosen

direction

(«A» or «B»)

Green arrow of single

access is lit in chosen

direction and red LED

display is lit in

opposite direction

Make sure that in case of

gentle push in the direction of

authorized access rotor starts

rotating and stops after rotation

to 120º.

Rotor should not start rotation

independently

3 Single access in

both directions

Push both

«SINGLE»

access buttons to

access in two

directions

(«A» or «B»)

Green arrows of single

access are lit in both

directions

Make sure that in case of

gentle push in the direction of

authorized access rotor starts

rotating and stops after rotation

to 120º.

Rotor should not start rotation