2. Test your repair before regular operation of the sprayer to

be sure that the problem is corrected. If the sprayer does

not operate properly, review the repair procedure to

determine if everything was done correctly. Refer to the

Troubleshooting Charts to help identify other possible

problems.

3. Make certain that the service area is well ventilated in

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Customer Service (U.S.) .......................

1-800-526-5362

Fax ................................................

1-800-528-4826

Customer Service (Canada) ..................

1-800-565-8665

Fax ................................................

1-905-856-8496

Customer Service (International)...........

1-201-337-1240

Fax ................................................

1-201-405-7449

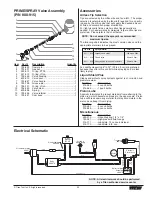

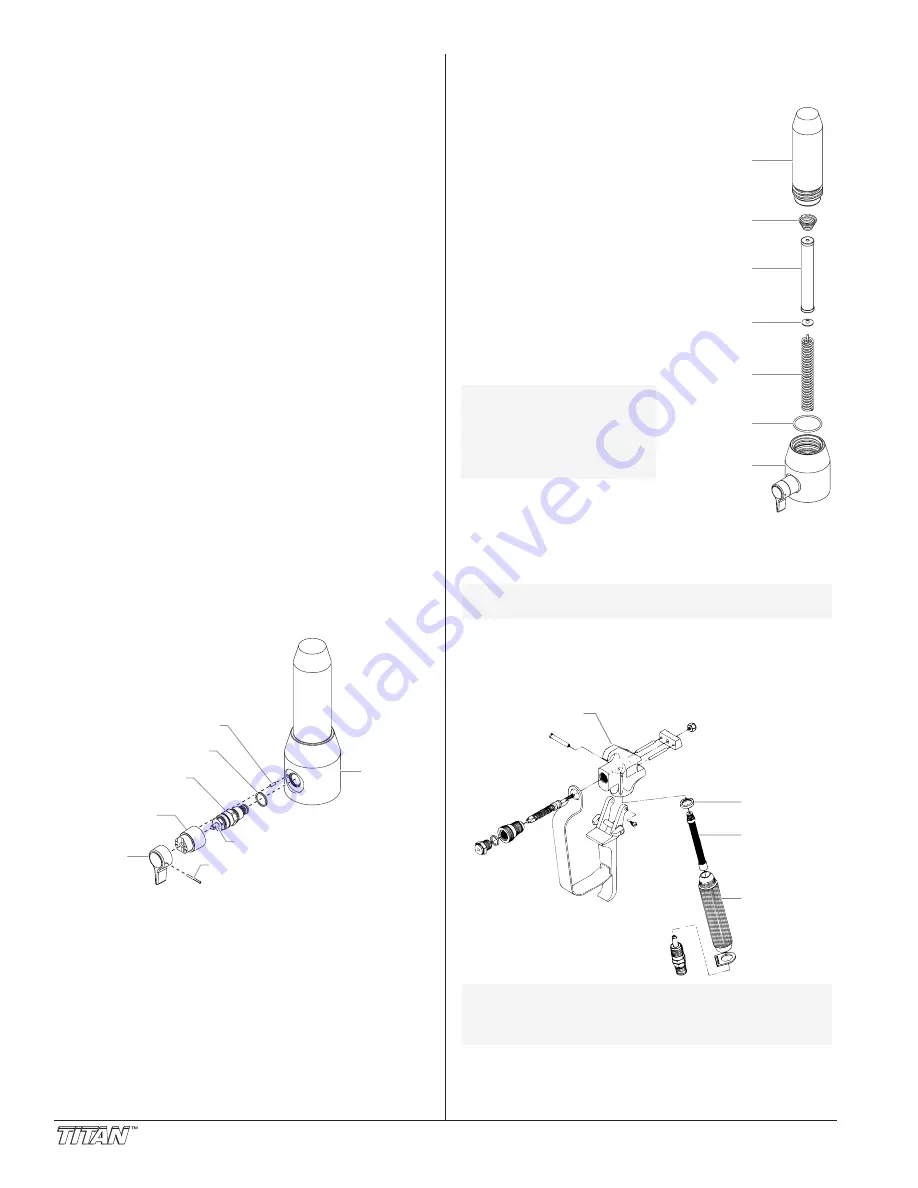

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 800-915.

1. Push the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new

valve housing assembly into the filter block. Tighten

securely with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the filter block using the dowel pin.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

Gasket

Dowel Pin

Cam Base

Valve Stem

Filter

Housing

Valve Housing

Assembly

Valve

Handle

Groove Pin

8

© Titan Tool Inc. All rights reserved.

Replacing the Filters

Pump Filter

1. Loosen and remove the filter

body by hand.

2. Slip the filter off of the core

spring.

3. Inspect the filter. Based on

inspection, clean or replace

the filter.

4. Inspect the o-ring. Based on

inspection, clean or replace

the o-ring.

5. Slide the new or cleaned

filter over the core spring

with the filter spring adapter

in place. Push the filter into

the center of the filter

housing.

6. Slide the filter body over the

filter and thread it into the

filter housing until secure.

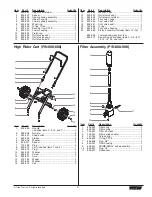

Gun Filter

1. Move the gun trigger lock to the unlocked position.

2. Loosen and remove the handle from the gun body.

3. Turning clockwise, unscrew the filter from the gun body.

4. Turning counterclockwise, screw the new or cleaned filter

into the gun body.

5. Make sure the handle seal is in position and thread the

handle into the gun body until secure.

6. Move the gun trigger lock to the locked position.

NOTE: For more detail, part number information, and

assembly drawings at larger scale, please see

the LX -80 Professional Airless Gun Owner's

Manual (#313-012).

Gun Body

Handle Seal

Filter

Handle

NOTE: Left-handed threads require turning the filter

clockwise to remove.

NOTE: The filter body

should be hand-

tightened, but make

sure it is seated

fully into the filter

housing.

Filter Body

Filter Spring

Filter Spring

Adapter

Core Spring

Filter

O-ring

Filter Housing